CNC machine tool is a digitally controlled machine tool. Its working principle is to identify and translate the specified programs and codes through the control system and display these programs and codes with numbers. After processing by the control device, various commands are issued to guide the machine tool to produce mechanical products according to the requirements of the drawings.

CNC machine tools usually consist of 5 parts: host, CNC equipment, drive equipment, auxiliary equipment, and programming equipment. The job of the host machine is to process and produce parts. Numerical control equipment is the main control system. Its hardware equipment includes monitors, paper tape readers, printed circuit boards, etc., and software equipment is some programs used to complete production. Drive equipment is the main power equipment of CNC machine tools. Auxiliary equipment, including lighting, lubrication, etc., is a device that enables CNC machine tools to successfully complete material processing.

Numerical control technology is a high-tech and new technology in modern industrial production. With the development of precision manufacturing technology and automation technology, numerical control technology is not only a digital control process but a combination of mechanical design technology, automation technology, manufacturing process technology, computer technology, modern control technology, sensor detection technology, and network communication technology, etc.

There are many advantages of numerical control technology, and it can have the advantages of flexible automation, high efficiency, and high precision at the same time. Numerical control technology has the functions of microelectronics, computers, information processing, automatic detection and control technology. With the continuous update of the development of machinery manufacturing and automation technology, numerical control technology is updated faster and faster.

Application of Numerical Control Technology

CNC machining involves general machinery and machine tools, aerospace engineering, bridges, ships, automobiles, communication industries, energy, construction, and other fields. The application of numerical control technology can handle the processing of complex structures, such as the whole aircraft structure, aircraft fuselage, submarine structure, robot, and so on. Numerical control technology can be applied to large-scale engineering construction, such as oil drilling derricks, building bridges, etc.

Application in Industrial Production

In the specific industrial production process, the automation of production is realized by inputting the computer program code into the computer, and then through the specific program.

In some production lines with a harsh working environment, such as welding or painting and other production links. CNC machining can improve labor conditions, and can also ensure production efficiency and personal safety. The application of CNC machine tool technology to industrial production enables industrial products to be produced in accordance with unified standards, improves the standardization of products, improves industrial production efficiency and product quality, and saves labor.

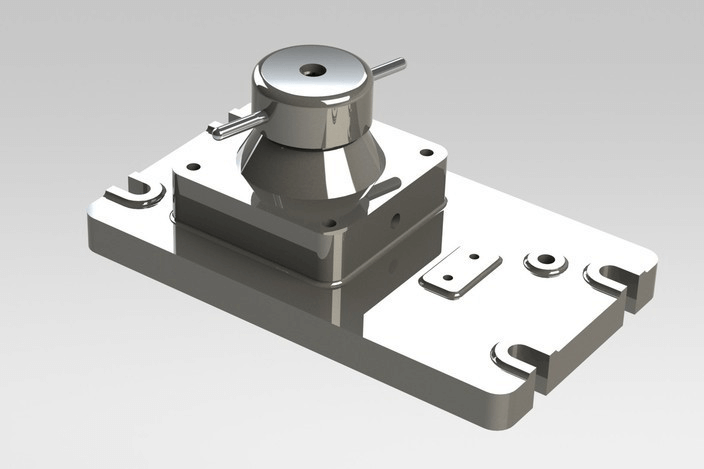

Application of Machine Tools

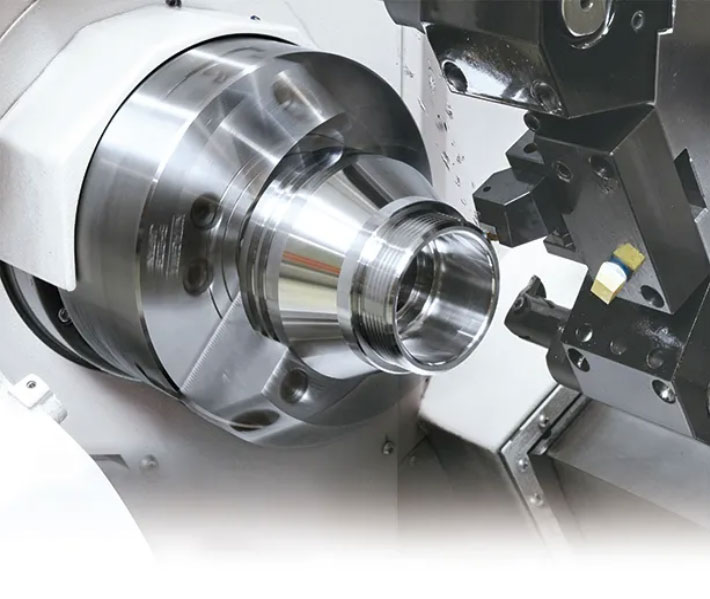

The manufacture of mechanical equipment is a very important part of modern industrial production. With the rapid development of the modernization process, there are also higher requirements for the machinery manufacturing industry, so machine tools with control capabilities are an indispensable part of the machinery manufacturing industry in today’s society.

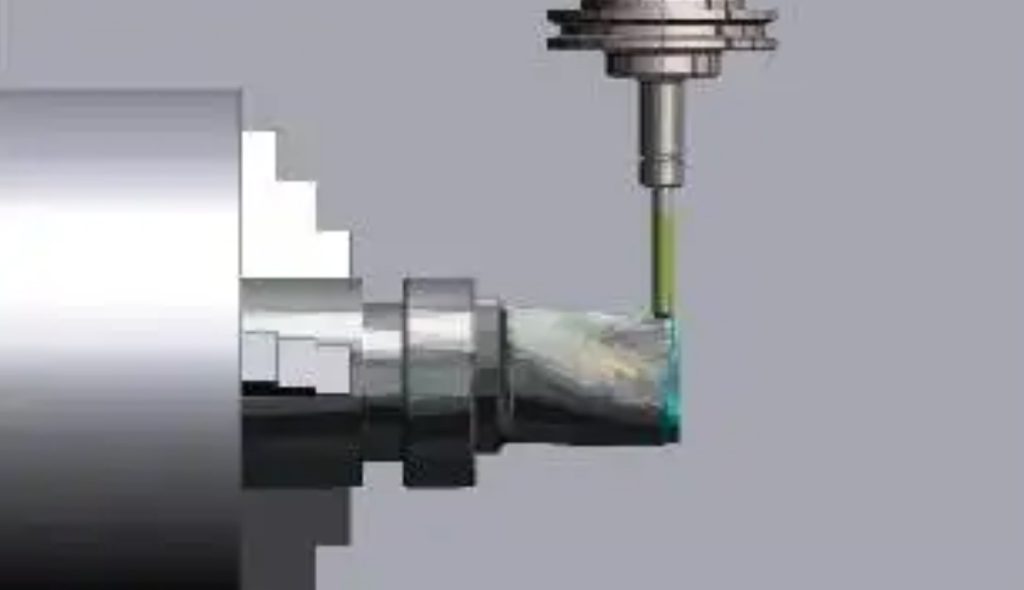

Computer numerical control technology can give the machine tools in the manufacturing industry a good control ability, and a computer control device can be installed in the machine tool, that is, to realize the application of numerical control technology in the machine tool. Numerical control technology can code and control the corresponding production links, and then issue corresponding commands to control the operation of the machine tool, which can make the machine tool automatically produce the required components.

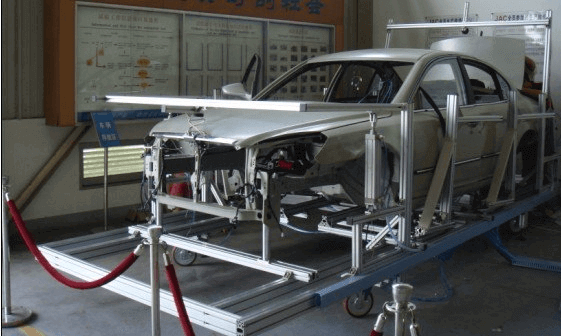

Applications in the Automotive Industry

Automobile crankshaft processing requires high production efficiency, good processing accuracy, strong flexibility, and a high degree of automation. After processing the crankshaft, fine grinding can be performed directly, eliminating the need for rough grinding. The application of numerical control technology in the machining of automobile crankshafts can solve this requirement.

Application in the Aviation Industry

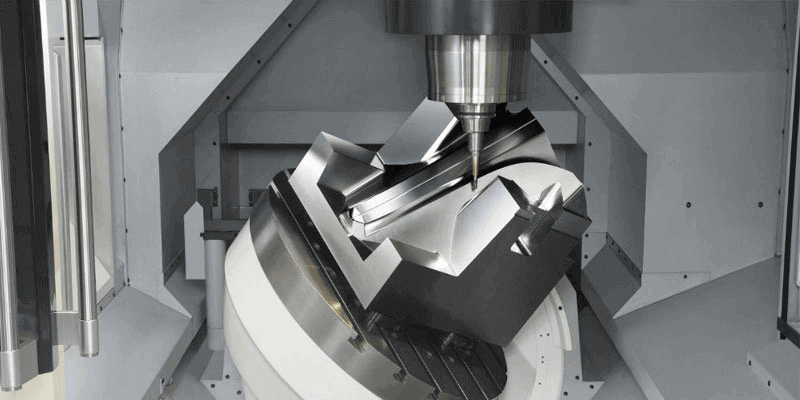

The aerospace field has very high material requirements for the parts it processes. Parts in the aerospace field require high precision, and some parts have poor rigidity. The application of numerical control technology can effectively solve these problems.

In the field of CNC machining, high-speed cutting technology has become a reality. Compared with traditional technology, numerical control technology is more flexible and precise, which can save energy and reduce expenses in the process of component production, and can improve the economic benefits of enterprises. Therefore, numerical control technology is widely used in the aviation industry, which is very important for the development of the aviation industry.

Application in the Medical Field

With the development of medical technology, CNC machine tool technology has further improved in the medical field. Numerical control technology can meet the requirements of very high precision for the equipment and equipment required by medicine.

Conclusion

JTR can have advanced CNC machine tools and can provide reliable one-stop CNC machining services. We can provide custom 3-axis, 4-axis, and 5-axis CNC machining services, as well as custom and wholesale services for small, medium, and large parts.