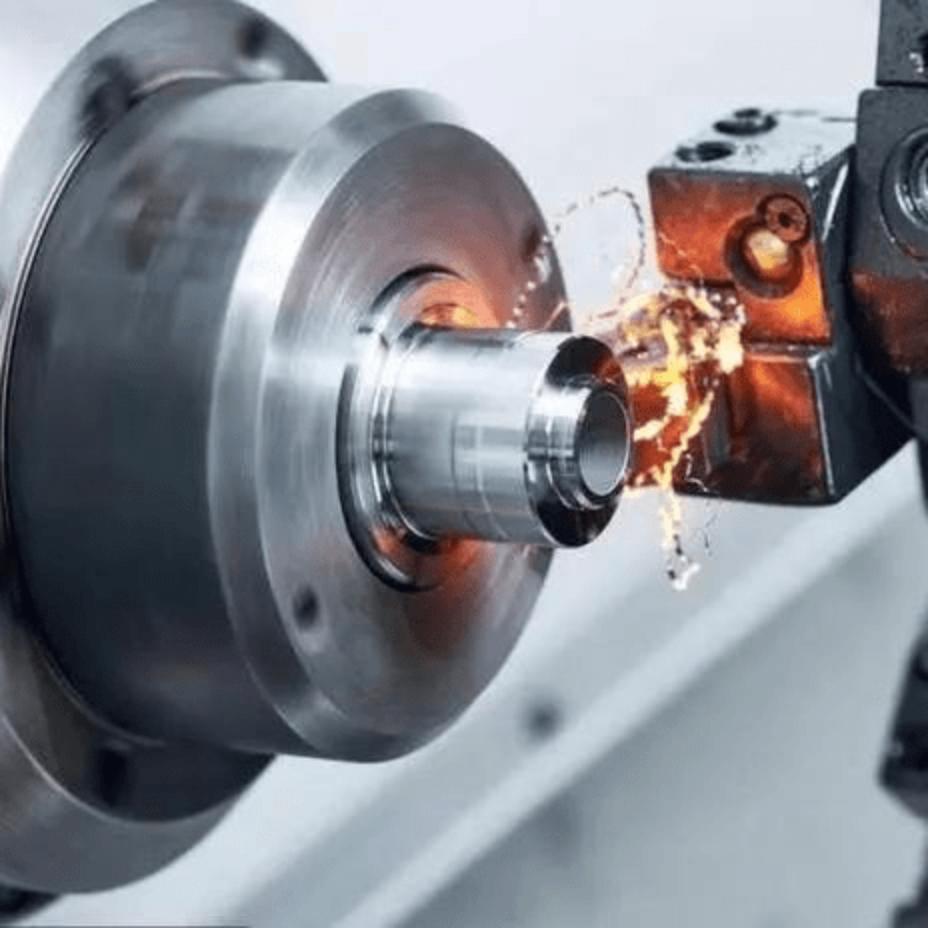

CNC machining, or Computer Numerical Control machining, is a manufacturing process in which computer-controlled machines create parts from a block of material such as metal, plastic, or wood. These machines are programmed with specific instructions that direct them in precisely moving cutting tools to remove material and create the desired shape and features of the finished part. Combining the versatility of CNC machining with the desirable properties of aluminum opens up a world of possibilities for producing strong, lightweight, and precisely crafted parts. If you’re looking for a versatile and cost-effective way to produce high-quality parts, this powerful combination could be the answer.

How Strong Is CNC-Machined Aluminum?

CNC-machined aluminum is a popular material for a variety of applications due to its unique set of properties. However, in terms of strength, it can be significantly stronger than pure aluminum, with a UTS ranging from approximately 270 MPa to more than 580 MPa, depending on the alloy and temper. It’s critical to recognize that there is no single answer. The strength of CNC-machined aluminum is dependent on several factors.

Factor 1: Aluminum Alloy

- 6061-T6: This versatile alloy has good strength, weldability, and corrosion resistance, making it ideal for a variety of applications. Its ultimate tensile strength (UTS) is approximately 310 MPa (45,000 PSI).

- 7075-T6: This high-strength alloy is commonly used in aerospace and military applications due to its excellent UTS of 434-580 MPa (63,000-84,000 psi). However, it is less machinable and more prone to corrosion than 6061-T6.

- 5052: This non-heat-treatable alloy has good corrosion resistance and formability, but lower strength than 6061-T6 and 7075-T6. Its UTS is approximately 270 MPa (39,000 PSI).

Factor 2: Temper

The temper is a heat treatment process that alters the microstructure and mechanical properties of aluminum alloys. For example, “T6” denotes a solution heat treatment followed by aging, which significantly improves strength over the annealed condition.

Factor 3. Geometry and Design

The shape and design of the CNC-machined part can also affect its strength. For example, a thin, unsupported section is weaker than a thicker, reinforced one. Additionally, stress concentrations around sharp corners can result in premature failure.

Factor 4. Machining Process

The CNC machining aluminum parts process itself has the potential to affect the final part’s strength. Cutting speeds, feed rates, and tool selection can all have an impact on material integrity and residual stress levels.

Is CNC-Machined Aluminum Lightweight?

Absolutely! CNC-machined aluminum is one of the lightest metals, with high strength and machinability. Here’s why.

Density

Aluminum has a significantly lower density than many other commonly used metals, including steel and copper. This means that for the same volume, an aluminum part will be significantly lighter. However, simply being light is not enough. We also need the material to be strong enough for the intended use. Aluminum excels in this area, providing high strength for a low weight. Aluminum’s machinability is also enhanced by its lower density. It is typically easier and faster to machine than denser metals, allowing for more intricate and complex designs. This contributes to weight optimization by removing unnecessary material during the machining process.

Machining Process

CNC machining, as opposed to traditional casting or forging processes, allows for the removal of material with extreme precision. This means that only the necessary material remains, resulting in a much lighter finished product than bulkier methods. CNC machining allows you to program and control the cutting and tool paths. This allows engineers to optimize the part’s design by strategically placing material where it is needed for strength while removing it from non-critical areas. This targeted approach results in a lightweight part that retains the required strength.

Strength-to-Weight Ratio

The strength-to-weight ratio essentially tells us how much weight a material can support relative to its weight. Aluminum, for example, has a high strength-to-density ratio. This means that you can achieve the same level of structural integrity with an aluminum part that weighs significantly less than a steel part.

Is CNC-Machined Aluminum Corrosion-Resistant?

The answer to whether CNC-machined aluminum is corrosion-resistant is determined by two factors: the aluminum alloy used and the environmental conditions to which it will be exposed. In general, most CNC-machined aluminum parts have good corrosion resistance, particularly when compared to other common metals such as steel. Aluminum forms a thin layer of aluminum oxide on its surface when exposed to air. This oxide layer acts as a barrier, preventing the underlying metal from further corrosion. However, the level of corrosion resistance varies greatly depending on the aluminum alloy used. Below are some of the most common alloys and their corrosion resistance:

- 6061: This is a versatile and widely used alloy with excellent overall corrosion resistance, making it appropriate for a wide range of applications.

- 5052: This alloy is highly corrosion resistant, particularly in marine environments, but it has a lower strength than 6061.

- 7075: This high-strength alloy resists corrosion well in most environments, but it is less resistant to saltwater and other harsh conditions than 6061 or 5052.

Furthermore, the environmental conditions in which the CNC-machined aluminum part will be used can influence its corrosion resistance. Salt water exposure, humidity, and pollution are all factors that can accelerate corrosion.

Conclusion

The statement, “Building Stronger, Lighter Products With CNC Machined Aluminum” is more than just a slogan; it expresses the unique benefits that this material and manufacturing process provide. It emphasizes the superior strength-to-weight ratio, resulting in lighter, more efficient, and long-lasting products with improved performance and design flexibility. This combination makes CNC-machined aluminum an extremely appealing option for a wide variety of applications. JTR provides CNC machining services. If you need them, please contact us.