In the dynamic realm of manufacturing, striking the perfect balance between budgetary constraints and top-notch product quality remains an enduring challenge. A pivotal player in this delicate dance is CNC 6061 aluminum, renowned for its versatility, cost-effectiveness, and exceptional machining capabilities. As industries seek precision engineering without compromising financial prudence, CNC 6061 aluminum emerges as a cornerstone material, especially when partnered with expert CNC machining services like those provided by JTR Machinery in China.

What is CNC 6061 Aluminum?

CNC 6061 aluminum, a heat-treatable alloy with excellent machinability, has gained popularity for its balance of strength and weight. Comprising aluminum, magnesium, and silicon, it is known for its corrosion resistance and weldability. These qualities, combined with its cost-effectiveness, make it an ideal material for a wide range of applications.

Why Choose CNC 6061 Aluminum?

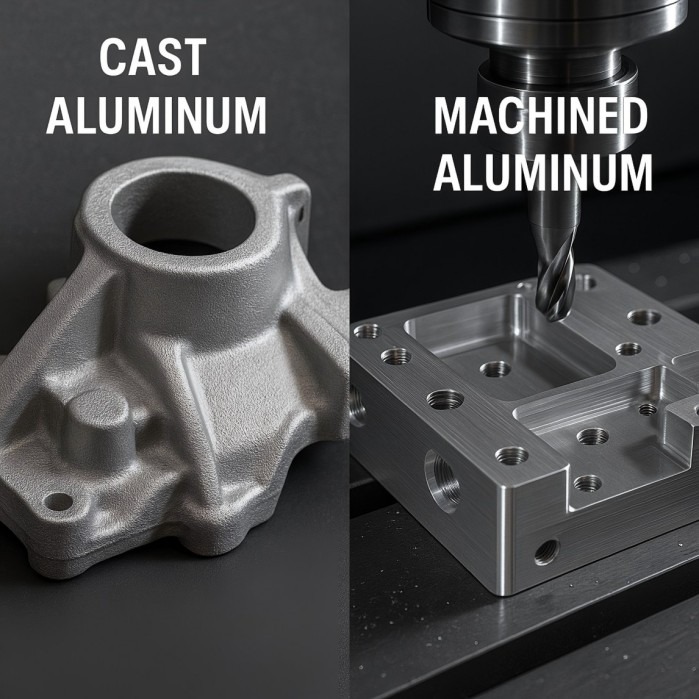

Precision Machining with CNC 6061 Aluminum:

One of the standout features of CNC 6061 aluminum is its suitability for precision machining. Computer Numerical Control (CNC) machining processes, such as milling and turning, are seamlessly applied to this material, enabling manufacturers to achieve intricate designs and tight tolerances. This makes it an excellent choice for industries demanding precision, such as aerospace, automotive, and electronics.

Cost-Efficiency in Production:

The cost-effectiveness of CNC 6061 aluminum is multifaceted. Its availability and widespread use contribute to competitive pricing in the market. Additionally, the ease with which it can be machined reduces production times and, consequently, labor costs. This makes CNC 6061 aluminum an attractive option for companies aiming to optimize their manufacturing processes while maintaining high-quality standards.

Weight-to-Strength Ratio:

In industries where weight is a critical factor, such as aerospace and automotive, CNC 6061 aluminum shines. Its impressive strength-to-weight ratio allows for the creation of robust components without adding unnecessary heft. This characteristic not only enhances overall product performance but also contributes to fuel efficiency and cost savings in transportation.

Corrosion Resistance for Longevity:

The corrosion resistance inherent in CNC 6061 aluminum translates into extended product longevity, mitigating maintenance costs over time. This feature proves invaluable in outdoor applications, marine environments, and any scenario where exposure to harsh weather conditions is a concern. As industries prioritize sustainable and long-lasting solutions, CNC 6061 aluminum emerges as a frontrunner.

Sustainable and Recyclable:

Beyond its immediate benefits, CNC 6061 aluminum aligns with the growing emphasis on sustainability in manufacturing. Aluminum is fully recyclable, and the recycling process requires only a fraction of the energy needed to produce it from raw materials. This makes CNC 6061 aluminum an eco-friendly choice, appealing to environmentally conscious businesses and consumers alike.

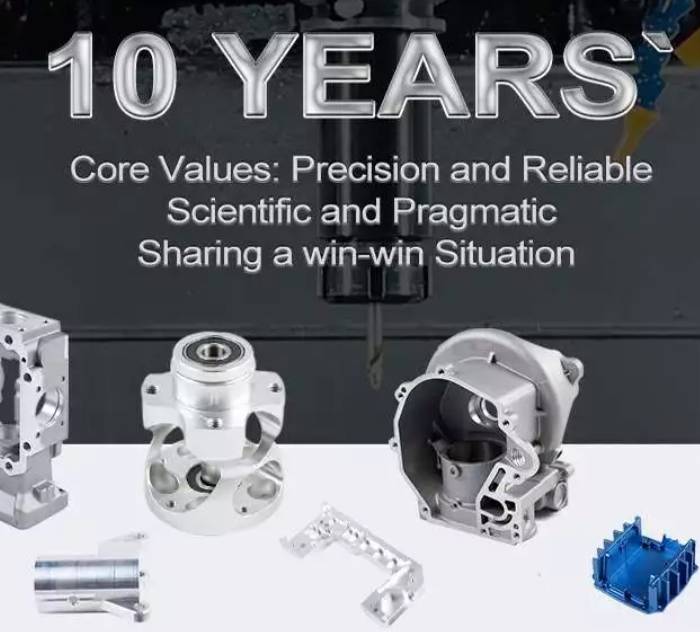

JTR Machinery: Elevating CNC Machining Excellence

In the realm of CNC machining in China, JTR Machinery stands out as a paragon of precision and reliability. Their expertise in handling CNC 6061 aluminum, coupled with state-of-the-art machinery, ensures that clients receive unparalleled service. The synergy of CNC 6061 aluminum and JTR Machinery’s proficiency offers a compelling solution for businesses seeking optimal precision within budgetary constraints.

Conclusion:

In the quest for cost-effective precision, CNC 6061 aluminum emerges as a standout solution. Its versatility, machinability, and cost-effectiveness make it a top choice for industries demanding precision engineering while managing budget constraints. As technology continues to advance, CNC machining with materials like 6061 aluminum opens up new possibilities, offering a perfect blend of affordability and quality for manufacturers across various sectors. As we look to the future, it’s evident that the marriage of precision and budget considerations will find a reliable partner in CNC 6061 aluminum.