Steel is a vital material used in countless applications due to its strength and durability. However, its Achilles’ heel is its susceptibility to corrosion, which can significantly reduce its lifespan and structural integrity. One of the most effective methods to protect steel from corrosion is hot dip galvanizing. This process not only enhances the longevity of steel but also provides robust protection in a variety of environments. This article delves into how hot dip galvanizing protects steel, exploring the process, the protective mechanisms of zinc coating, its benefits, and how it compares to other protection methods.

Understanding the Hot-Dip Galvanizing Process

Hot dip galvanizing involves immersing steel in molten zinc, resulting in a metallurgical bond between the zinc and steel. The process can be broken down into several key steps:

- Surface Preparation: The steel surface is cleaned to remove dirt, oil, and other contaminants through degreasing. This is followed by pickling in a dilute solution of hydrochloric or sulfuric acid to remove mill scale and rust.

- Fluxing: The cleaned steel is dipped in a flux solution, usually zinc ammonium chloride, to prevent oxidation before galvanizing.

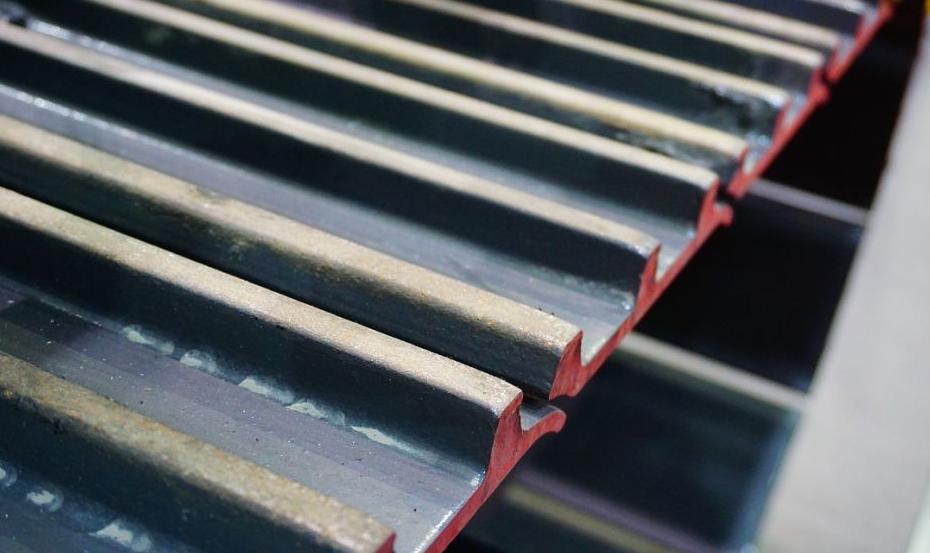

- Galvanizing: The steel is immersed in a bath of molten zinc at temperatures around 450°C (840°F). The zinc reacts with the steel to form a series of zinc-iron alloy layers topped with a layer of pure zinc.

- Cooling and Finishing: After galvanizing, the steel is cooled, often in a quench tank, and inspected for quality.

Mechanisms of Zinc Coating Protection

Hot dip galvanizing protects steel through a combination of barrier protection, cathodic protection, and self-healing properties. Each of these mechanisms plays a critical role in preventing corrosion and ensuring the longevity of the steel.

Barrier Protection

The primary mechanism by which hot dip galvanizing protects steel is through barrier protection. The zinc coating acts as a physical shield that prevents corrosive elements such as water, oxygen, and chloride ions from reaching the steel surface. This barrier is particularly effective because zinc is highly resistant to atmospheric corrosion. The galvanized layer consists of multiple intermetallic layers of zinc-iron alloy topped with pure zinc, providing a robust and impervious coating that protects the steel beneath.

Cathodic Protection

In addition to acting as a physical barrier, the zinc coating provides cathodic protection. This is a form of electrochemical protection where the zinc, being more electrochemically active (more anodic) than steel, serves as a sacrificial anode. In the presence of an electrolyte (such as water), the zinc corrodes preferentially to the steel. This sacrificial corrosion of the zinc layer means that even if the coating is damaged and the underlying steel is exposed, the surrounding zinc will corrode first, protecting the steel from rusting.

Self-Healing Properties

One of the remarkable features of hot dip galvanized coatings is their ability to self-heal. When minor scratches or abrasions occur, the exposed steel is still protected by the zinc. This self-healing occurs through a process called zinc patina formation.

When zinc corrodes, it forms zinc oxide, which further reacts with water and carbon dioxide in the atmosphere to form zinc carbonate. This zinc carbonate is a stable and adherent layer that can cover scratches and minor damage, effectively sealing the exposed steel and preventing further corrosion. This process ensures that the protection continues even after the coating has been physically damaged, significantly enhancing the durability and longevity of the galvanized steel.

The self-healing properties are particularly beneficial in environments where the steel is subject to mechanical wear or impact, such as in construction and transportation. This feature reduces the need for frequent maintenance and repairs, thereby lowering the overall lifecycle cost of the steel structure or component.

Benefits of Hot Dip Galvanizing

Hot dip galvanizing offers numerous benefits when used to protect steel, making it a preferred method in many industries. These benefits include:

Long-Term Durability

One of the most significant benefits of hot dip galvanizing is its ability to provide long-term protection. The zinc coating formed during the galvanizing process is highly resistant to corrosion and can last for decades, even in harsh environments. The metallurgical bond between the zinc and steel creates a durable layer that is less likely to be damaged by mechanical wear or environmental factors. This extended lifespan means that galvanized steel structures and components require less frequent maintenance and replacement, ensuring continued performance and reliability over time.

Cost-Effectiveness

While the initial cost of hot dip galvanizing may be higher than other corrosion protection methods, it is highly cost-effective in the long run. The extended lifespan and reduced maintenance requirements of galvanized steel lead to significant savings over the life of a project. Moreover, the predictability of maintenance and replacement schedules helps avoid unexpected costs. The reduced need for frequent repairs or recoating translates into lower overall costs, making hot dip galvanizing an economically attractive option for protecting steel.

Comprehensive Protection

Hot dip galvanizing provides comprehensive protection to steel structures. The zinc coating covers all surfaces of the steel, including edges, corners, and hard-to-reach areas that are often vulnerable to corrosion. This complete coverage ensures that no part of the steel is exposed to the environment, thereby preventing localized corrosion and enhancing the overall integrity of the structure. The uniformity of the coating, achieved through the immersion process, guarantees consistent protection across the entire surface of the steel.

Versatility

Hot dip galvanizing is a versatile process that can be applied to a wide range of steel products, from small fasteners to large structural beams. This versatility makes it suitable for numerous applications across various industries, including construction, automotive, agriculture, and energy. Galvanized steel is used in building frameworks, bridges, car bodies, farming equipment, and pipelines, among many other applications. The ability to galvanize complex shapes and sizes of steel components adds to the adaptability and utility of the process.

Environmental Advantages

Hot dip galvanizing is also beneficial from an environmental standpoint. Galvanized steel is highly recyclable, and the zinc coating does not interfere with the recycling process. This makes galvanized steel an environmentally friendly choice that supports sustainability. Additionally, the durability of galvanized steel reduces the need for frequent replacements, leading to less material waste over time. The galvanizing process itself adheres to stringent environmental regulations, ensuring that it has minimal impact on the environment.

Hot dip galvanizing offers a range of benefits that make it an excellent choice for protecting steel. Its long-term durability, cost-effectiveness, comprehensive protection, versatility, and environmental advantages combine to provide a robust and reliable method for preventing corrosion. These benefits ensure that galvanized steel remains a top choice in many industries, helping to extend the lifespan and performance of steel structures and components.

Comparison with Other Protection Methods

When it comes to protecting steel from corrosion, several methods are available, each with its own advantages and disadvantages. Here, we compare hot dip galvanizing with other common steel protection methods: painting and coatings, electroplating, and using corrosion-resistant alloys.

| Criteria | Hot Dip Galvanizing | Painting and Coatings | Electroplating | Corrosion-Resistant Alloys |

| Process | Immersion in molten zinc | Application of paint or protective coatings | Application of a thin metal layer using electric current | Alloying with elements like chromium, nickel |

| Durability | Long-term (decades) | Moderate; regular maintenance required | Moderate; requires frequent maintenance | High; excellent resistance to corrosion |

| Coverage | Comprehensive; all surfaces including edges | Variable; may not cover edges and corners well | Uniform but thin coating | Comprehensive; inherent material property |

| Self-Healing Properties | Yes; minor scratches self-repair through zinc oxidation | No | No | No |

| Cathodic Protection | Yes; zinc acts as a sacrificial anode | No | Limited; dependent on coating integrity | No |

| Initial Cost | Moderate to high | Low to moderate | Moderate | High |

| Maintenance | Low | High; requires regular repainting | Moderate to high; frequent touch-ups needed | Low |

| Aesthetic Flexibility | Limited; typically not as smooth or customizable | High; available in various colors and finishes | High; smooth and uniform finish | High; often has a high-quality, attractive finish |

| Environmental Impact | Recyclable; minimal impact | Dependent on paint/coating used | Dependent on materials used | Recyclable; durable lifespan reduces waste |

| Application Versatility | High; suitable for various shapes and sizes | High; can be applied on-site | High; precise control over thickness | Limited by cost and material availability |

This comparison highlights the distinct advantages and trade-offs of each steel protection method. Hot dip galvanizing provides robust, long-lasting protection with minimal maintenance, making it ideal for many industrial applications. Painting and coatings offer aesthetic flexibility but require frequent maintenance. Electroplating provides a smooth finish but offers less durable protection. Corrosion-resistant alloys offer excellent durability but at a significantly higher cost. The best choice depends on specific application needs, environmental conditions, budget, and desired lifespan.

Conclusion

Hot-dip galvanizing is a reliable and cost-effective method for protecting steel from corrosion. It provides a long-lasting, durable, and versatile solution for various applications. If you’re looking to extend the lifespan of your steel structures and equipment, hot-dip galvanizing is a strong option to consider. Professional hot-dip galvanizing service please feel free to contact JTR. They can also provide you other surface finishing services.