As we all know, electroplating is a process of plating a thin layer of other metals or alloys on the metal surface using the principle of electrolysis, thereby preventing metal oxidation, improving wear resistance, corrosion resistance, electrical conductivity, light reflectivity, and enhancing aesthetics.

During electroplating, the plated metal or other insoluble materials are used as the anode, the workpiece to be plated is used as the cathode, and the solution containing the cations of the plated metal is used as the electroplating solution, and then the cations of the plated metal are reduced on the surface of the workpiece to be plated to form a coating. What is the difference between the common electroplating zinc, nickel electroplating, and chromium electroplating?

What is Electro Galvanizing?

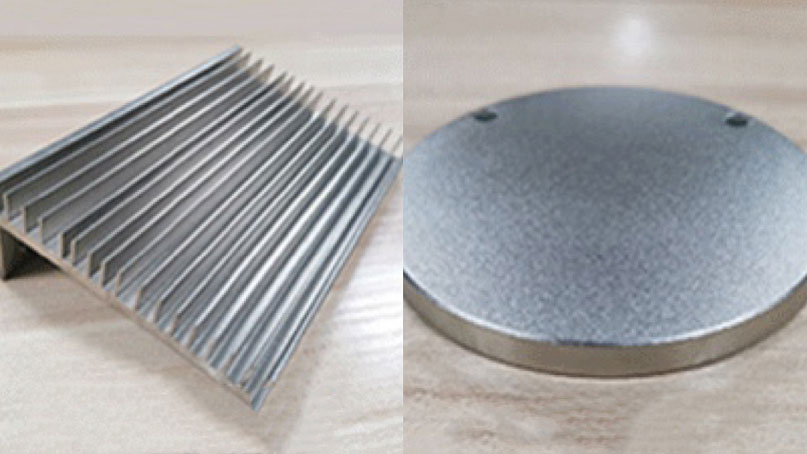

Electro galvanizing is a process of forming a uniform, dense, and well-bonded metal or alloy deposition layer on the surface of the workpiece by using the principle of electrolysis.

Features of Electro-galvanizing:

- Compared with other metals, zinc is a relatively cheap and easily plated metal.

- The color after galvanizing is the silvery white of zinc.

- After passivation after plating, it can show different colors such as black, color, army green, etc. Passivation can increase the protective properties and decorative properties of the plated parts.

Applications of Electro Galvanizing:

- Widely used to protect steel parts, especially to prevent atmospheric corrosion. It can effectively improve the corrosion resistance and service life of steel parts.

- Can also be used to add a decorative appearance.

What is Electroplating Chrome?

Electroplating chrome is divided into electroplating hard chrome and decorative chrome.

Electroplating hard chrome is generally used on the surface of the product position of the mold. After chrome plating, the mold and workpiece will have the advantages of smooth surface, smooth surface, easy demoulding, and no rust.

Electroplating decorative chrome refers to chrome plating on a pre-polished surface to obtain a silver-blue mirror-like finish.

Features of Chrome Plating:

- Chrome plating on pre-polished surfaces results in a silver-blue specular finish.

- The decorative chrome layer has good gloss, strong reflective ability, and excellent decorative properties. It also has excellent hardness and wear resistance.

- The molds and workpieces treated with chrome plating have the following advantages:

(1) The surface is flat, smooth, and easy to demould.

(2) Will not rust.

(2) Increase hardness, corrosion resistance, acid resistance, and wear resistance.

Applications of Chrome Plating:

- Electroplating hard chrome is generally used on the surface of the product position of the mold.

- Decorative chrome plating can be used for protection and decoration. Exposed parts such as automobiles, bicycles, trains, medical equipment, light industrial products, metal furniture, etc. require decorative chrome plating.

What is Electroplating Nickel?

Electroplated nickel is silvery white with some yellow in it. Electroplated nickel is mainly used as a protective decorative coating. Can prevent corrosion, and increase wear resistance, gloss, and aesthetics.

Features of Electroplated Nickel:

- Corrosion Resistance: Nickel has excellent corrosion resistance, making electroplated nickel coatings ideal for protecting metal substrates from rust and degradation caused by exposure to harsh environments.

- Hardness: Electroplated nickel coatings can be engineered to provide hardness levels suitable for specific applications, offering wear resistance and durability.

- Uniformity: The electroplating process allows for the creation of uniform nickel coatings with consistent thicknesses, ensuring even protection and coverage over the entire substrate surface.

- Smoothness: Electroplated nickel coatings can be deposited to achieve smooth and uniform surfaces, which is beneficial for applications requiring low friction or contact resistance.

- Ductility: Nickel coatings can exhibit good ductility, allowing them to conform to the shape of the substrate and withstand deformation without cracking or peeling.

- Adhesion: Properly prepared substrates and optimized electroplating processes can result in strong adhesion between the nickel coating and the substrate, ensuring long-term performance.

Applications of Electroplating Nickel:

- Protective and decorative coating: Nickel plating is widely used on household items like plumbing fixtures, doorknobs, and car parts to improve their corrosion resistance and appearance.

- Functional applications: Nickel plating is used on machine parts, tools, and electronics to enhance wear resistance and improve overall functionality.

- Base layer for other plating: Due to its good adhesion properties, nickel is often used as a base layer before applying other decorative or functional coatings like chrome plating.

- Electroforming: Thick nickel deposits can be created through electroplating to make molds, printing plates, and other industrial items.

Differences between Electroplated Zinc, Electroplated Nickel, and Electroplated Chromium

Zinc, nickel, and chromium are all popular choices for electroplating, but they each offer distinct advantages and disadvantages:

Electroplated Zinc:

- Pros: Most affordable option, good sacrificial protection (corrodes first to protect underlying metal), widely available.

- Cons: Offers less corrosion resistance than nickel or chromium, dull gray appearance.

Electroplated Nickel:

- Pros: Excellent corrosion resistance, good wear resistance, ductile and malleable, bright and attractive finish.

- Cons: More expensive than zinc, can be susceptible to hydrogen embrittlement in some high-strength steels.

Electroplated Chromium:

- Pros: Superior corrosion resistance, very hard and wear-resistant, high luster and shine.

- Cons: Most expensive option, chromium plating can be hazardous due to the use of hexavalent chromium (Cr(VI)), environmental regulations restrict its use in some areas.

Here’s a table summarizing the key differences:

| Property | Electroplated Zinc | Electroplated Nickel | Electroplated Chromium |

| Base Metal | Typically steel or iron | Various metals, often steel or brass | Typically steel or brass |

| Corrosion Resistance | Moderate | High | Excellent |

| Wear Resistance | Moderate | Good | Excellent |

| Aesthetic Appeal | Moderate | Moderate | Excellent |

| Common Applications | Automotive, construction, household appliances | Automotive, aerospace, electronics | Automotive trim, plumbing fixtures, appliances |

| Surface Finish | Typically dull gray to shiny | Bright and attractive | Bright, reflective |

| Coating Durability | Moderate | Good | Excellent |

| Cost | Low | Medium | High |

The three common electroplating processes and the differences between them are briefly described above. As a professional manufacturer dedicated to providing high-quality rapid prototyping and mass manufacturing services, JTR can provide a variety of surface treatment services, including various types of electroplating processes. We clearly understand the differences and characteristics of different processes and can customize the most suitable manufacturing solution according to your needs. If you need it, please feel free to contact us.