We often hear the words casting and forging in mold making. How to tell the difference between these two manufacturing processes? Should we choose casting or forging in mold making?

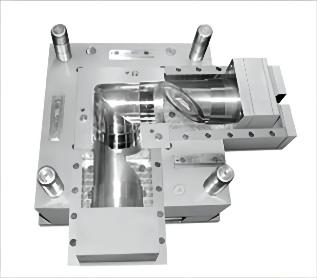

Why do we need mold making?

Mold making refers to the transformation of raw materials into molds through CNC machining and other methods and then mass production of parts through abrasive tools.

How it works is simple? First, the mold designer designs the mold structure through the computer (or draws the drawings by hand) according to the requirements of the product (part), and then the skilled workers pass various mechanical processing (such as lathes, milling machines, machining centers) according to the requirements of the drawings, EDM, wire cutting, etc.) do a good job of each part on the mold and then assemble and debug until qualified products can be produced.

The advantage of mold making is that parts or products can be mass-produced through molds, reducing costs; making parts through molds can achieve ultra-high-efficiency production (currently, no production method can achieve the efficiency of molds), and it guarantees product accuracy, and at the same time The mold is easy to realize automatic production.

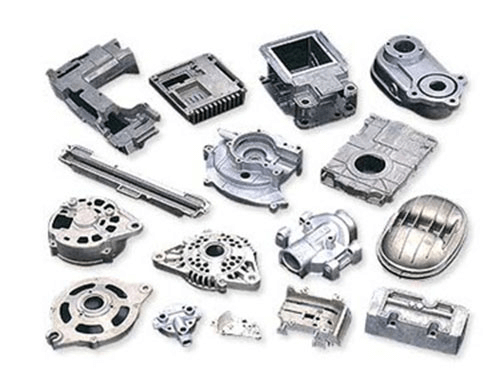

Manufacture of molds by casting

Casting is a process of smelting metal into a liquid that meets certain requirements, pouring it into a mold, cooling, solidifying, and cleaning to obtain a casting (part or blank) with a predetermined shape, size and performance. The basic technology of the industry.

The cost of the blank produced by casting is low, and it is more economical for parts with complex shapes, especially with complex inner cavities; at the same time, it has wide adaptability and good comprehensive mechanical properties. But the materials (such as metal, wood, molding materials, etc.) and equipment (such as sand mixers, molding machines, metallurgical furnaces, core making machines, shakeout machines, shot blasting machines, cast iron flat plates, etc.) required for casting production are relative. It will produce dust, harmful gas, and noise and pollute the environment.

Types of mold casting

The casting method of the mold is customarily divided into:

①Ordinary sand casting, including wet sand, dry sand, and chemically hardened sand.

②Special casting can be divided into special casting with natural mineral sand and gravel as the main molding material according to the molding material (such as investment casting, mud casting, negative pressure casting, solid casting, casting workshop shell casting, ceramic casting, etc.) and special casting with metal as the main casting material (such as metal mold casting, pressure casting, low-pressure casting, continuous casting, centrifugal casting, etc.).

Casting process

① Preparation of casting molds (containers that make liquid metal into solid castings), casting molds can be divided into sand molds, metal molds, ceramic molds, clay molds, graphite molds, etc. according to the materials used; they can be divided into disposable and semi-permanent types according to the number of uses and permanent type. The main factor affecting the quality of castings is the quality of mold preparation.

② Melting and pouring of cast metals, cast metals (cast alloys) mainly include cast steel, cast iron, and cast non-ferrous alloys;

③ Casting treatment and inspection. Casting treatment includes:

- Removing foreign matter on the core and casting surface.

- Removing pouring risers.

- Shoveling burrs and seams, and other protrusions.

- Heat treatment.

- Shaping.

- Anti-rust treatment.

- Rough machining.

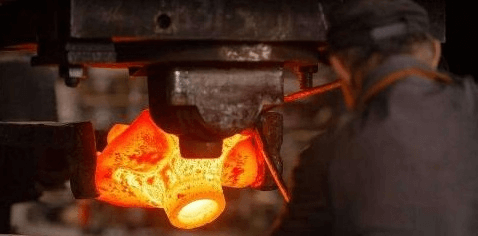

Manufacture of molds by forging

Forging is the use of a forging press to apply pressure to a metal blank to deform it plastically. Finally, the processing method of forgings with certain shapes, sizes, and mechanical properties is obtained.

Manufacturing molds by forging can eliminate as-cast porosity and welding holes in the metal of the mold, and the mechanical properties of forgings are generally better than those of castings of the same material.

Important parts in machinery with high loads and severe working conditions are mostly manufactured by forging, except for rolling plates, profiles, or welded parts with simple shapes.

Forging is divided by forming a method

- Open forging (free forging)

Using impact force or pressure to deform the metal between the upper and lower stanchions (anvil blocks) to obtain the required forgings, mainly two types are manual forging and mechanical forging.

- Closed mode forging

The metal blank is compressed and deformed in a forging die cavity with a certain shape to obtain a forging, which can be divided into die forging, cold heading, rotary forging, extrusion, etc.

According to deformation temperature

Forging can be divided into hot forging (processing temperature is higher than the recrystallization temperature of the billet metal), warm forging (lower than the recrystallization temperature), and cold forging (normal temperature).

Forging materials are mainly carbon steel and alloy steel of various compositions, followed by aluminum, magnesium, titanium, copper, etc., and their alloys. The original state of the material is a bar, ingot, metal powder, and liquid metal. The ratio of the cross-sectional area of the metal before deformation to the cross-sectional area of the die after deformation is called the forging ratio. Correct selection of forging ratio can improve product quality and reduce costs.

How to choose forging or casting to make molds?

For mold making, both forging and casting have unique advantages. We should choose a relatively suitable processing method according to the mold’s physical characteristics and the mold’s requirements.

At JTR, to ensure that the customized molds can fully display the mold characteristics and improve the service of the molds, we will recommend different mold making methods according to the different needs of customers.