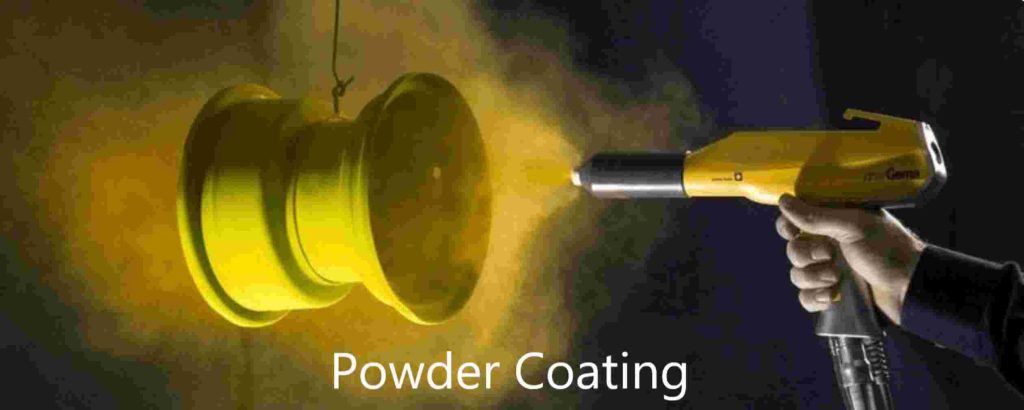

Powder coating is a modern and popular dry-finishing technique that uses finely ground polymer particles instead of traditional liquid paint. These vibrant, free-flowing powders are electrostatically applied to a grounded surface before being heat-cured to create a long-lasting, appealing finish. Unlike liquid paint, powder coating does not use solvents or thinners, making it a more environmentally friendly option. Liquid paint, the traditional surface finisher, is a wet mixture of pigments, binders, and solvents that provides color, protection, and, in some cases, texture to various surfaces. In contrast to powder coating, which is applied as a dry powder, liquid paint is applied as a fluid and solidifies through natural drying or heat curing. Is Powder Coating Better Than Liquid Paint?

Main Differences Between Powder Coating and Liquid Paint

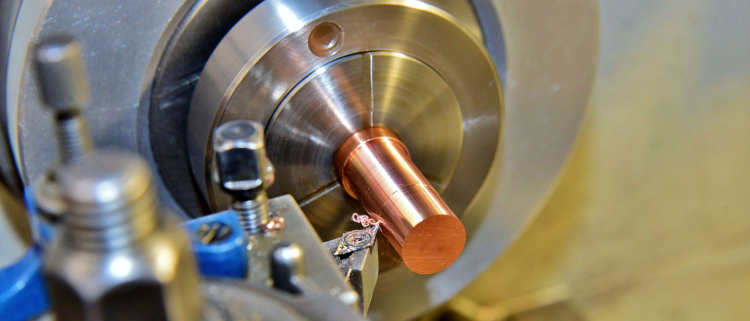

- Powder Coating: Powder coating involves electrostatically applying a dry powder to a grounded surface. The powder is then baked to form a hard, durable finish. This method is typically more environmentally friendly than liquid painting because it generates less waste and does not use solvents.

- Liquid paint: Liquid paint is applied wet with a brush, roller, or sprayer. The paint must then dry naturally or be cured in an oven. Liquid paint can be more difficult to apply evenly than powder coating, and it is also more prone to scratches and chips.

Performance Comparison between powder coating and liquid paint

Durability

Powder coating creates a thicker, more uniform layer than liquid paint. This extra thickness translates to better overall protection against physical damage such as scratches, dents, and abrasions. The electrostatic application and subsequent curing of powder coating form a chemical bond with the underlying surface. This bond is significantly stronger than the mechanical adherence of liquid paint, increasing resistance to chipping, peeling, and flaking.

Corrosion Protection

Powder coating produces a thicker, more continuous film than liquid paint. This thicker layer provides better barrier protection against corrosive elements such as moisture, salt, and chemicals. Consider it a stronger wall that protects your metal from the elements. Liquid paint application can leave tiny gaps or imperfections, especially around corners or complex shapes. These gaps serve as entry points for corrosion to begin its insidious work. The electrostatic application of powder coating ensures a more uniform and consistent coating, reducing these vulnerable spots. In essence, powder coating’s thicker, more uniform layer, superior adhesion, solvent-free nature, and long-lasting finish create a more robust barrier against corrosion than liquid paint. As a result, it is the preferred choice for applications such as outdoor furniture, automotive parts, industrial equipment, and any metal surface exposed to harsh environments.

Finish Quality

Powder coating typically produces a thicker film than liquid paint. This translates to improved scratch and chip resistance, which protects the underlying surface for a longer period. Powder coatings are available in a wide range of matte, gloss, textured, and metallic finishes that are difficult to achieve with liquid paint. This adaptability enables greater design flexibility and customization. The cured finish of powder coating is highly resistant to UV rays, chemicals, and extreme temperatures, retaining its color and appearance for years to come. As a result, it is ideal for outdoor applications and surfaces subjected to harsh conditions.

How Long Does Powder Coating Last Compared to Liquid Paint?

Powder coating has a much longer lifespan than liquid paint, with estimates ranging from 20 to 40 years for properly applied powder coating, whereas even high-quality liquid paint may show significant wear and tear after 5 to 10 years. Factors that contribute to Powder Coating’s Durability:

- Thicker Film: Powder coatings typically form a thicker layer than liquid paint, providing better resistance to abrasions, scratches, and chips.

- Chemical Bonding: Powder particles melt and chemically bond to the underlying surface during the curing process, resulting in a more permanent and resilient bond than liquid paint’s physical adhesion.

- Resistant to Environment: Powder coatings outperform liquid paints in harsh environments, withstanding UV rays, extreme temperatures, and chemicals better.

- Minimal Maintenance: In comparison to liquid paint, the durable finish requires less maintenance and touch-ups, extending its lifespan even further.

While liquid paint has a shorter and less durable finish, its ease of application and wider color options may still suit some specific needs. Powder coating, on the other hand, is the clear winner in terms of longevity for projects that require long-lasting protection, superior aesthetics, and minimal maintenance.

Conclusion

Choosing the incorrect method based on incorrect information can result in disappointment. Knowing the limitations of each method prevents you from expecting a long-lasting finish on surfaces that aren’t suitable for liquid paint or an exact color match with powder coating. Using the incorrect method can result in a waste of time, money, and materials. Choosing the best one for the surface and the desired outcome ensures success and prevents the need to redo the work later. Using an incompatible method can cause damage to the surface. Understanding the suitability of each approach for various materials helps to avoid irreversible damage and costly repairs. JTR is a professional company dedicated to providing powder coating services and other surface finishing services. For more information, please contact us.