CNC machining plastic has emerged as a vital process in the manufacturing industry. Offering precision, flexibility, and a wide range of applications, plastic machining services have become indispensable for producing high-quality components. In this article, we will explore the fascinating world of CNC machining plastic, with a particular focus on CNC milling plastic.

What is CNC Machining Plastic?

CNC machining plastic, short for Computer Numerical Control machining, involves the use of automated machinery to shape and finish plastic components with exceptional precision. This technology allows manufacturers to create intricate and complex parts, making it a popular choice in industries like aerospace, automotive, medical, and electronics.

Plastic machining services utilize a variety of plastic materials, each chosen for its unique properties and suitability for specific applications. Plastics such as acrylics, polycarbonates, polypropylenes, and nylon are commonly used due to their versatility, durability, and ease of machining.

What is CNC Milling Plastic? Precision Action in CNC Machining Plastic?

One of the most widely used processes within CNC machining plastic is CNC milling. It involves the removal of material from a plastic workpiece using rotary cutters in a controlled and precise manner. Here’s a closer look at CNC milling plastic:

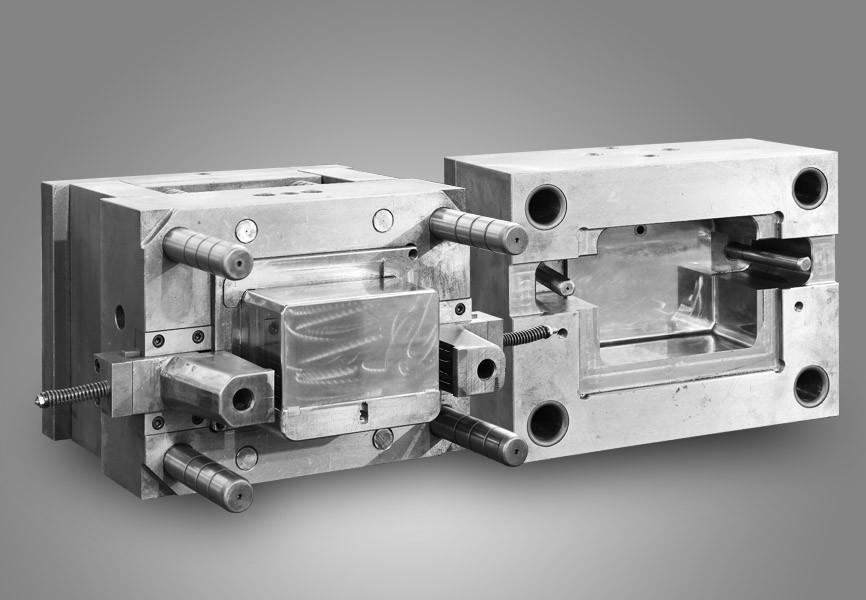

- Material Preparation: The process begins with selecting the appropriate plastic material. The choice depends on factors like the application’s requirements, material properties, and budget considerations. Once chosen, the plastic is cut or molded into a workpiece of the desired size and shape.

- Programming: A crucial step in CNC milling plastic is programming the CNC machine. Skilled operators use Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software to create a detailed blueprint of the part. This digital model guides the CNC machine’s movements, specifying toolpaths, cutting depths, and other essential parameters.

- Tool Selection: Selecting the right cutting tools is vital for achieving precision in plastic machining. Tools are chosen based on factors like the plastic material, desired finish, and intricacy of the part. Carbide end mills and high-speed steel tools are commonly used for milling plastic.

- Machining Process: With the program loaded and tools in place, the CNC milling machine executes the machining process. The cutting tools rotate at high speeds, and the machine precisely follows the programmed toolpaths to remove excess material. CNC milling plastic allows for intricate shapes, fine details, and tight tolerances.

- Quality Assurance: Throughout the CNC milling plastic process, quality checks and inspections ensure that the final part meets exact specifications. This attention to detail helps maintain the high standards required for various applications, from medical devices to aerospace components.

6 Key Advantages of CNC Machining Plastic

CNC machining plastic offers several advantages, making it a preferred choice for many industries:

- Precision: CNC milling plastic delivers unparalleled precision and consistency, even for complex and intricate geometries. This precision ensures that parts meet tight tolerances and quality standards.

- Versatility: Plastic machining services can handle a wide range of plastic materials, allowing manufacturers to choose the best-suited material for each application.

- Cost-Effectiveness: CNC machining plastic is cost-effective for both prototyping and production runs. Efficient toolpath optimization and minimal material waste contribute to cost savings.

- Rapid Prototyping: CNC machining plastic is ideal for rapid prototyping, allowing engineers to quickly test and refine designs before mass production.

- Durability: Many plastic materials used in CNC machining offer excellent durability, corrosion resistance, and lightweight properties, making them suitable for demanding environments.

- Reduced Lead Times: The automated nature of CNC machining reduces lead times, enabling faster production and quicker time-to-market for products.

Conclusion

CNC machining plastic has revolutionized the manufacturing industry by providing precision, versatility, and cost-effectiveness. Among the various plastic machining services available, CNC milling plastic stands out as a key player in creating intricate and high-quality plastic components. With the continuous advancement of technology and materials, CNC machining plastic will continue to play a vital role in shaping the future of manufacturing. Whether it’s for aerospace, automotive, medical, or countless other applications, CNC machining plastic remains a driving force behind innovation and progress in various industries.