CNC vs. Forging vs. Die Casting:Which Bicycle Manufacturing Processes Fit Your Part?

The choice of process determines a part’s performance, cost, and…

The choice of process determines a part’s performance, cost, and…

Due to its good machinability, corrosion resistance, and its potential…

The global manufacturing landscape has witnessed a significant shift, with…

The demand for precise, lightweight, and durable aluminum parts continues…

Can CNC Machining Achieve Tight Tolerances?

How accurate is CNC machining?

The realm of precision manufacturing relies heavily on Computer Numerical…

What You Must Know Before Choosing CNC Machining Services

What is CNC Milling and Turning?

How to Use G41 and G42 in CNC Turning

As the automotive industry develops towards lightweight, intelligent and electrified,…

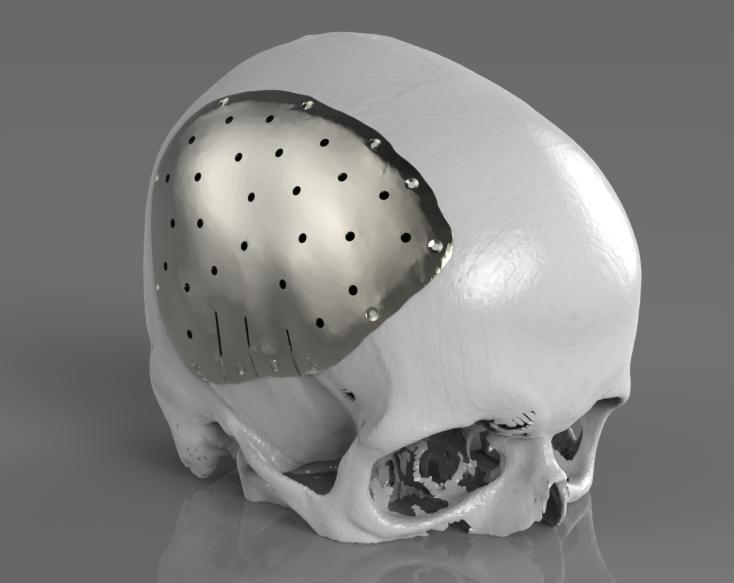

The human body is a complex and demanding environment. Medical…

Request A Quote