The demand for precise, lightweight, and durable aluminum parts continues to grow, making the selection of the right CNC machining service provider a critical decision. Here we share 10 key considerations to help you make an informed decision and give you a recommendation of a China CNC machining service supplier.

Consideration 1: Experience and Expertise

The longer a company has been providing Aluminum CNC Machining Services and the more diverse their project portfolio, the higher the likelihood they possess the expertise to handle complex projects and troubleshoot potential issues effectively. Experience translates to a deeper understanding of aluminum alloys, machining techniques, and industry best practices. Skilled machinists and engineers help achieve tight tolerances and high precision. When selecting an aluminum CNC machining provider, prioritize their experience and expertise in handling aluminum alloys.

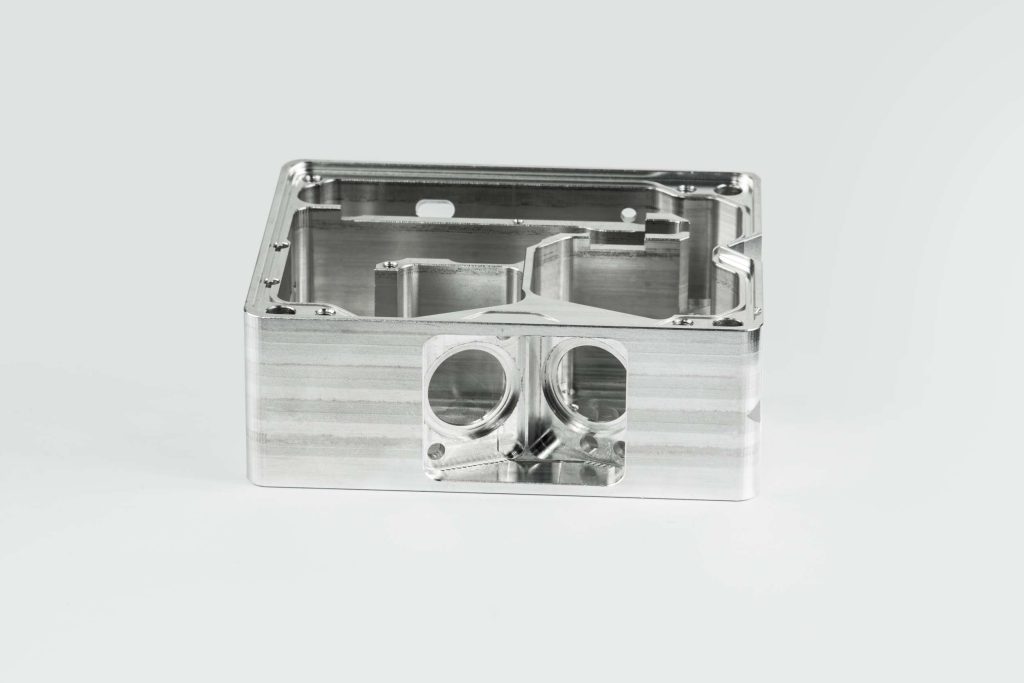

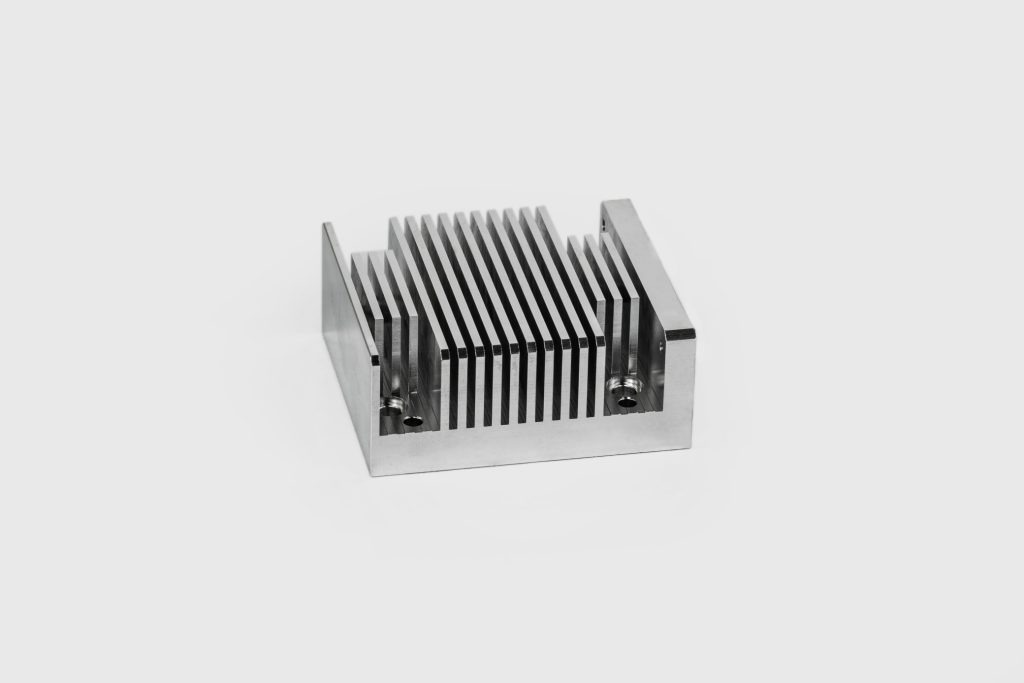

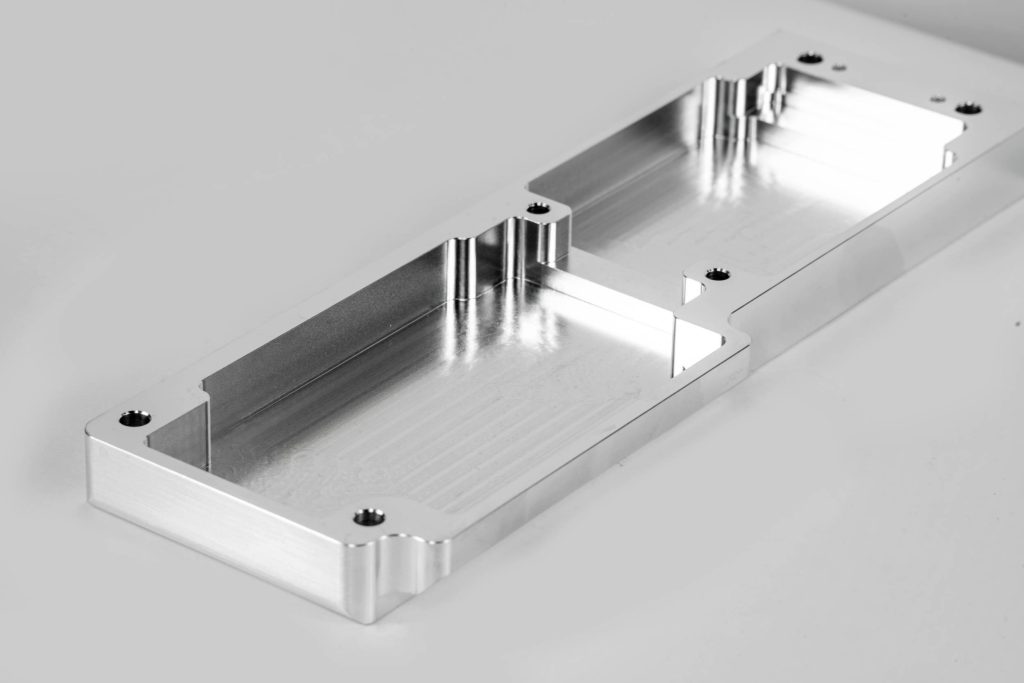

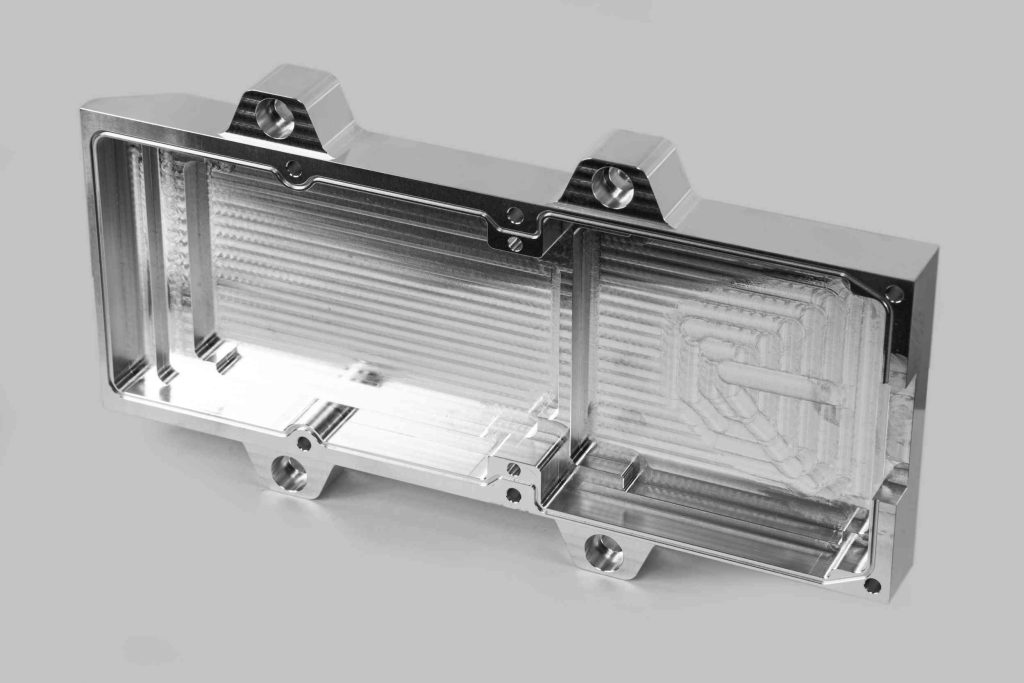

At JTR Machine, our extensive experience in providing Aluminum CNC Machining Services spans over 10 years. We have successfully completed numerous projects involving a wide range of aluminum alloys, including 6061, 7075, and 5052, for clients across various industries. For instance, we partnered with a leading aerospace company to produce intricate aluminum brackets for aircraft interiors, meeting stringent tolerances and demanding timelines. Our team of seasoned machinists and engineers brings a wealth of knowledge to every project, ensuring optimal machining strategies and high-quality outcomes for your Aluminum CNC Machining Services needs.

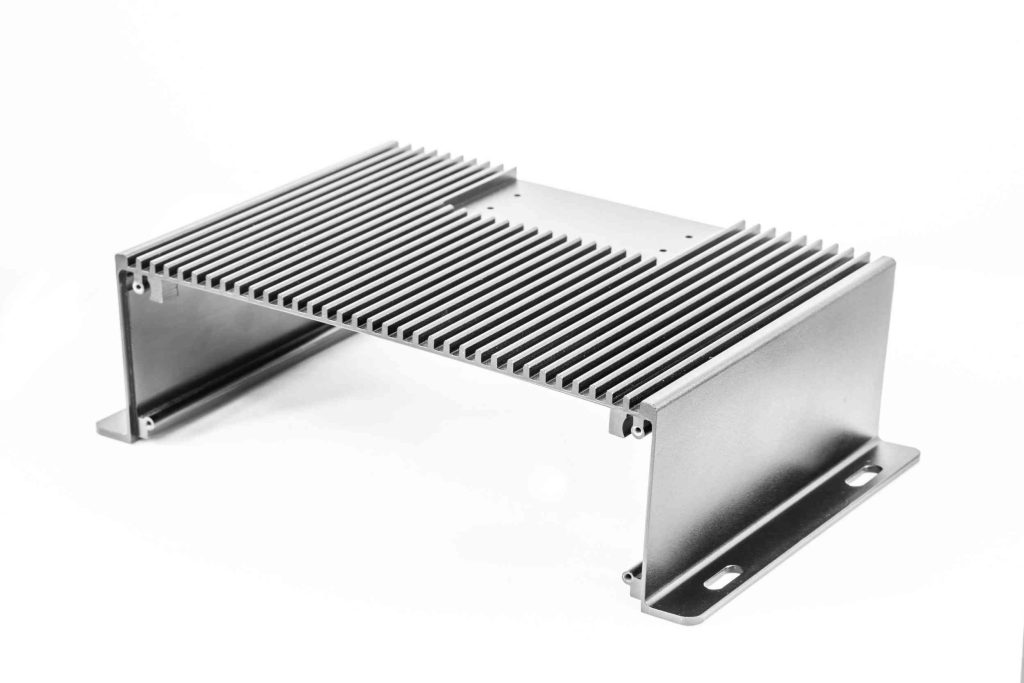

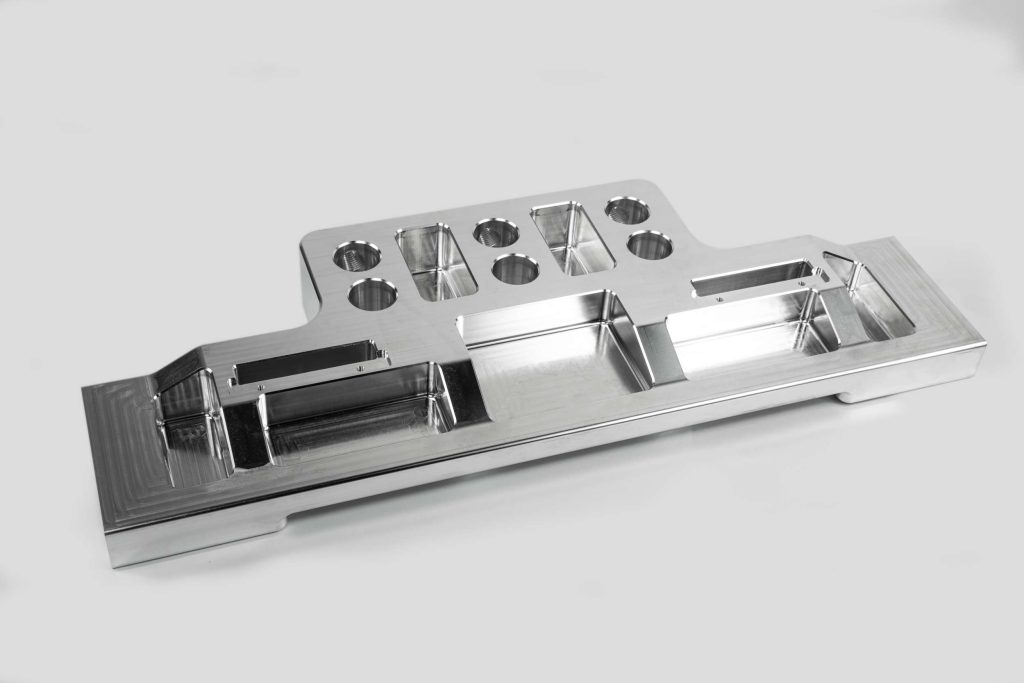

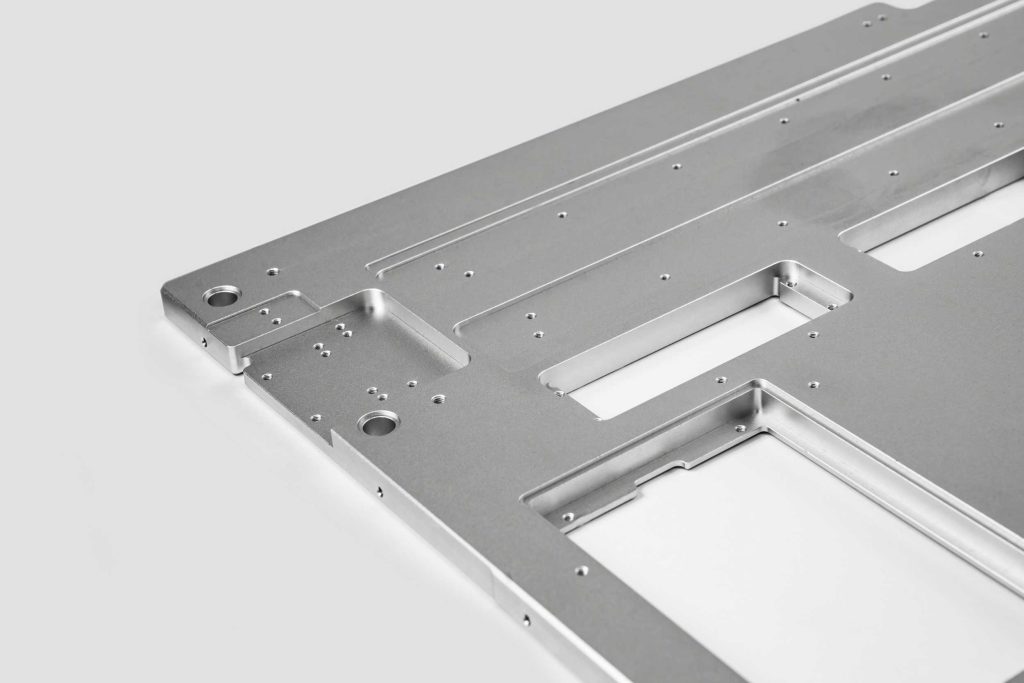

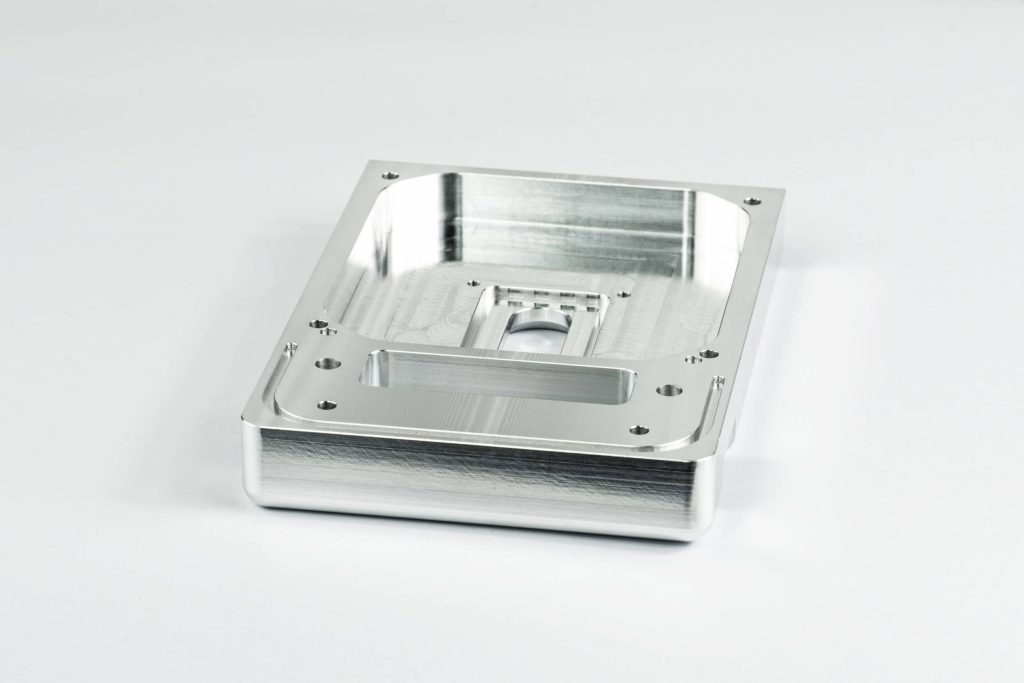

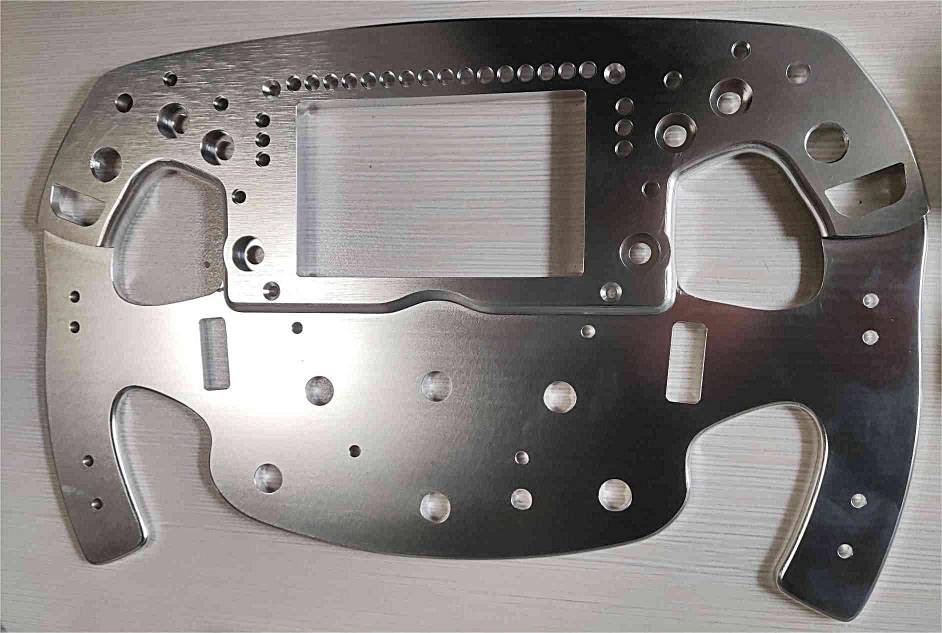

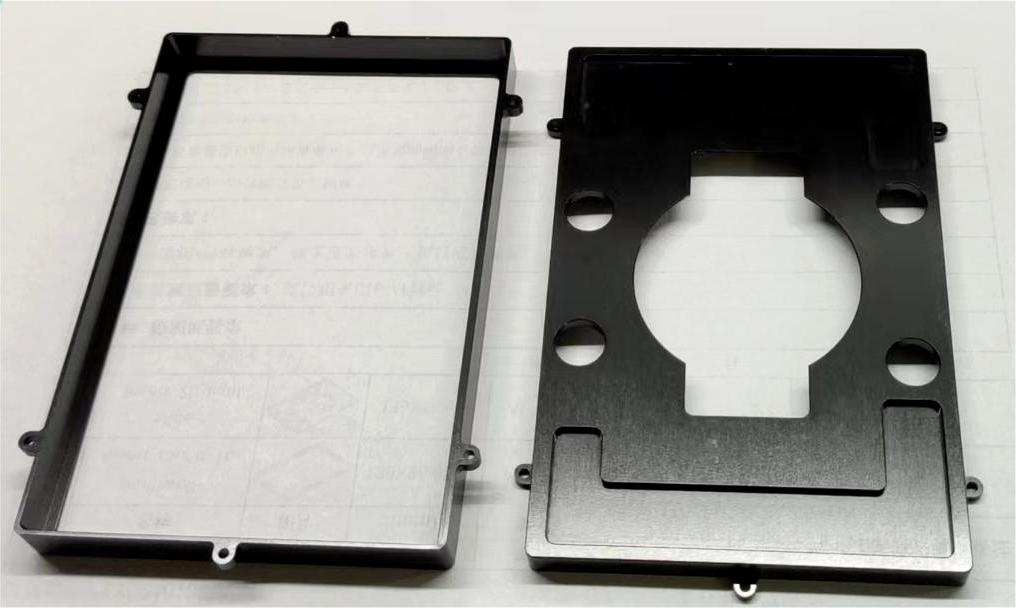

JTR CNC Machining Aluminum Parts:

Consideration 2: Technology and Equipment

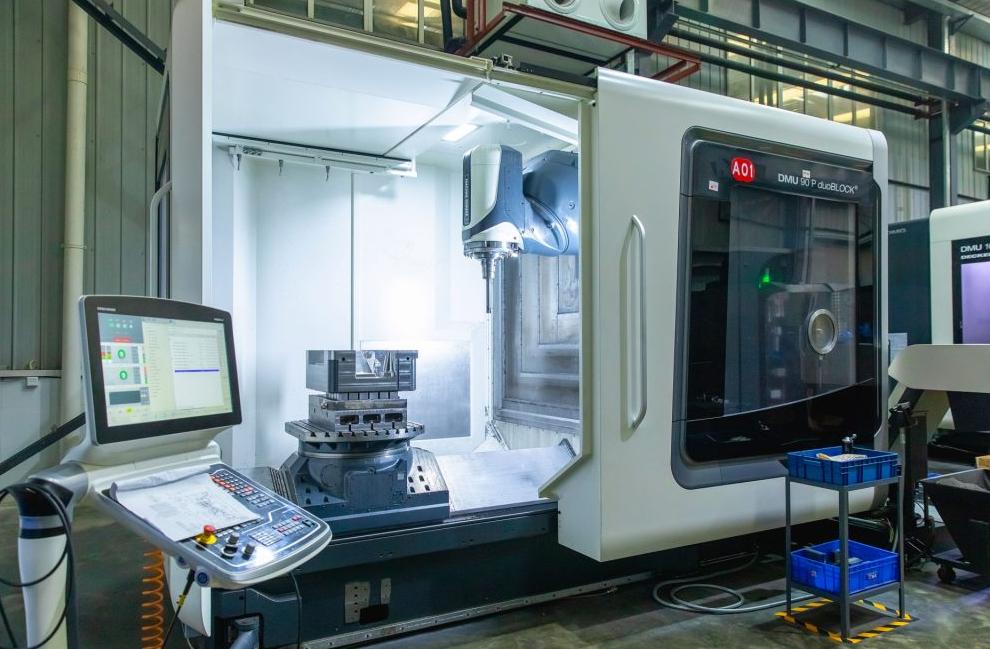

The sophistication and maintenance of a CNC machining service’s equipment directly impact the precision, efficiency, and complexity of the parts they can produce. Investing in advanced machinery demonstrates a commitment to quality and the ability to handle diverse Aluminum CNC Machining Services requirements.

JTR Machine has over 70 advanced CNC machines, including high-speed multi-axis milling machines and precision turning centers. Our continuous investment in technology ensures we can handle intricate geometries, tight tolerances (up to ±0.005mm), and demanding surface finishes for your Aluminum CNC Machining Services. For example, our 5-axis machining centers allow us to create complex aluminum parts in a single setup, reducing lead times and improving accuracy. This advanced technological infrastructure positions JTR as a leading provider of Aluminum CNC Machining Services.

Consideration 3: Quality Assurance and Precision

Quality assurance processes ensure that every part meets the required specifications and tolerances. This includes rigorous inspection processes, advanced metrology equipment, and adherence to quality management systems.

Quality is at the core of our Aluminum CNC Machining Services at JTR Machine. We implement a comprehensive quality assurance system that includes in-process inspections, final dimensional checks using Coordinate Measuring Machines (CMM), and material certifications. Our adherence to ISO 9001:2015 standards guarantees that every aluminum part we produce meets the highest quality standards and precise specifications. We provide detailed inspection reports upon request, ensuring complete transparency and confidence in our Aluminum CNC Machining Services.

Consideration 4: Material Selection and Availability

A reputable Aluminum CNC Machining Services provider should offer a range of aluminum alloys to meet the specific needs of different applications. They should also have reliable sourcing and efficient inventory management to ensure timely material availability.

JTR Machine understands the diverse requirements of Aluminum CNC Machining Services and maintains a readily available stock of various aluminum alloys, including the commonly used 6061, the high-strength 7075, and the corrosion-resistant 5052. Our established relationships with reputable material suppliers ensure consistent quality and timely procurement. Our experienced team can also advise on the most suitable aluminum alloy for your specific application, considering factors like strength, machinability, and cost-effectiveness for your Aluminum CNC Machining Services.

Consideration 5: Customization and Flexibility

A good provider offers tailored solutions to meet specific needs, from prototyping to large-scale production.

JTR Machine prides itself on offering highly customized Aluminum CNC Machining Services. We work closely with our clients from the initial design phase through to final production, accommodating design changes and varying order quantities. Whether you require a single prototype or a large batch of complex aluminum parts, our flexible manufacturing processes can adapt to your specific needs and timelines. Our engineering team is adept at optimizing designs for manufacturability, ensuring cost-effective and efficient Aluminum CNC Machining Services.

Consideration 6: Surface Treatment and Finishing Options

Depending on the application, aluminum parts may require specific surface treatments and finishes to enhance their properties, such as corrosion resistance, wear resistance, or aesthetic appeal. A comprehensive Aluminum CNC Machining Services provider should offer a range of these options.

JTR Machine offers a comprehensive suite of surface treatment and finishing options for your Aluminum CNC Machining Services.

| Finishes | Materials | Colors |

| Anodizing | Aluminum/Alloy aluminum/Other metal | Grass green, red, black, etc. |

| Chrome & Galvanized | Steel/Stainless steel/Alloy steel | Bright silver |

| Powder Coating | All metal | Black, blue, yellow, red, etc. |

| Polishing | All metal and plastic | / |

| Blasting | All metal | Black, blue, yellow, red, etc. |

JTR also offer other surface finishing options and logos & symbols, feel free to get a quote!

Consideration 7: Production Capacity and Lead Times

A reliable provider will tell you their production capacity and typical lead times before the project processing to ensure the timely delivery of your aluminum parts.

JTR Machine has a rapid prototyping capability with lead times as short as 1-2 days, and also has a scalable production capacity to handle both small and large volume orders for Aluminum CNC Machining Services. Our efficient workflow, coupled with our advanced equipment and skilled workforce, allows us to maintain competitive lead times without compromising on quality. If you have any specific requirements, we can provide estimated lead times, ensuring transparency and reliable Aluminum CNC Machining Services.

Consideration 8: Cost control

Balancing cost and quality is a significant consideration when choosing aluminum CNC machining services.

JTR Machine is committed to providing cost-effective Aluminum CNC Machining Services without sacrificing quality. We offer transparent pricing and work with our clients to identify opportunities for cost optimization through design modifications and efficient machining strategies. Our detailed quotes clearly outline all costs involved, ensuring no hidden fees. We strive to provide the best value for your investment in Aluminum CNC Machining Services.

Consideration 9: Customer Support and Communication

A clear and responsive communication ensures a smooth and successful machining project.

At JTR Machine, we prioritize clear and consistent communication throughout the entire Aluminum CNC Machining Services process. Our dedicated project managers serve as your primary point of contact, providing regular updates, addressing your inquiries promptly, and ensuring a seamless experience.

Consideration 10: Compliance and Certifications

Compliance with industry standards is vital for quality assurance and trust.

We understand the importance of compliance and ensure our processes and documentation align with the necessary regulations. We hold ISO 9001:2008 and IATF quality system certification. At the same time, we adhere to environmental regulations and sustainable practices. Practicing waste recycling and using energy-efficient machines, we try our best to protect the environment.

Choosing the right aluminum CNC machining service provider impacts the quality, cost, and success of your project. JTR Machine stands out with its expertise, advanced technology, stringent quality control, and commitment to customer satisfaction. By partnering with JTR, you gain access to high-quality products and reliable service for all your aluminum CNC machining needs.