What is Milled Steel?

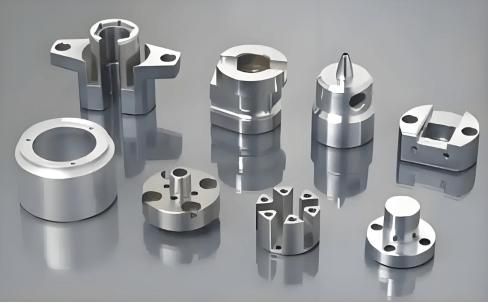

Milled steel refers to steel that has undergone a milling process, where a rotating cutting tool removes material to achieve the desired shape, surface quality, and dimensional accuracy.

Milled steel refers to steel that has undergone a milling process, where a rotating cutting tool removes material to achieve the desired shape, surface quality, and dimensional accuracy.

The performance and reliability of these motors hinge on the…

From the Wright brothers’ pioneering flight to today’s sophisticated jetliners…

The food processing industry relies heavily on specialized machinery to…

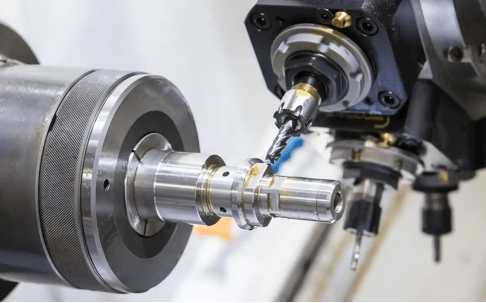

CNC machining, a subtractive manufacturing process that uses programmed computer…

Computer Numerical Control (CNC) machining has emerged as a cornerstone of…

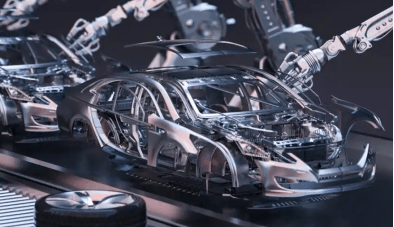

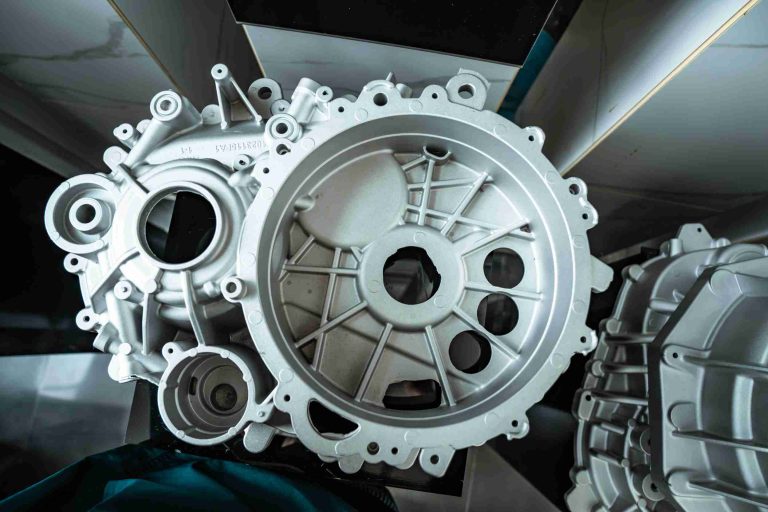

The automotive industry thrives on innovation, pushing the boundaries of…

CNC machining offers unparalleled precision in manufacturing and plays a pivotal…

Titanium alloys have emerged as a critical material in aerospace, medical,…

Brass and copper are widely used in various industries due…

Aluminum machining parts have become ubiquitous in modern industries. From…

CNC machining aluminum presents unique challenges that require careful consideration to…

Request A Quote