What is Electroless Plating?

Electroless plating is also called autocatalytic plating. This is a surface treatment method in which metal ions in the plating solution are reduced to metal by a suitable reducing agent without an applied current and then deposited on the surface of the part.

What Are the Characteristics of Electroless Plating?

1. Electroless plating is a new type of metal surface treatment technology.

2. The electroless plating process is simple, energy-saving, and environmentally friendly.

3. Electroless plating is widely used, with uniform coating and good decoration.

4. In terms of functionality, it can improve the electrical conductivity and lubricating properties of parts.

5. In terms of protective performance, the obtained parts have good corrosion resistance, good wear resistance, high gloss, high surface hardness, high-temperature resistance, and improved service life.

6. The obtained parts have high bonding strength: the bonding strength of the alloy layer and the metal base after electroless plating treatment increases.

7. The obtained parts have no obvious thickening at the sharp corners or edges and do not need to be ground after plating.

8. The process technology has strong adaptability and uniform coating: uniform coating can also be obtained on the inner surface of blind holes, deep holes, corners, gaps, etc.

What is the Principle of Electroless Plating?

The principle of electroless immersion plating technology is: the electroless plating process does not require electricity but uses a strong reducing agent in a solution containing metal ions to reduce metal ions to metal through a redox reaction, and then deposit on the surface of the part to form a dense coating.

Application of Electroless Plating

Copper and copper alloys, aluminum and aluminum alloys, cast iron, steel, die steel, and stainless steel can all be used as substrates for electroless plating.

What is Electroplating?

Electroplating is a process in which a metal film is attached to the surface of a part by electrolysis. It is to enhance the corrosion resistance of metals, increases hardness, prevents wear, and improves electrical conductivity, smoothness, heat resistance, and surface beauty. Electroplating is used on the outer layers of many coins.

What is the Principle of Electroplating?

Electroplating uses the principle of electrolysis. When electroplating, the workpiece to be plated is used as the cathode, and the plated metal or other insoluble material should be used as the anode. In the electroplating solution containing the cations of the plating metal, the cations of the plating metal can be reduced on the surface of the workpiece to be plated to form a plating layer.

What Are the Elements of Electroplating?

1. Cathode: workpiece to be plated.

2. Anode: The soluble anode is the metal to be plated. Insoluble anodes, mostly precious metals.

3. Electroplating solution: Contains metal ions to be plated.

4. Electroplating tank: the tank body that can withstand and store the electroplating solution. Factors such as strength, corrosion resistance, temperature resistance, etc. need to be considered.

5. Rectifier: A device that provides DC power.

What is the Difference Between Electroless Plating and Electroplating?

1. The principle is different: The principle of electroless plating is that under the catalysis of metal, the deposition process of metal is produced by a controllable redox reaction through a reducing agent, without the need for DC power equipment.

Electroplating uses the principle of electrolysis and requires DC power equipment

2. Electroless plating can deposit coatings on non-conductors.

3. Electroless plating has less waste liquid, lower cost, and less environmental pollution. It has gradually replaced electroplating in many fields and has become an environmentally friendly surface treatment process.

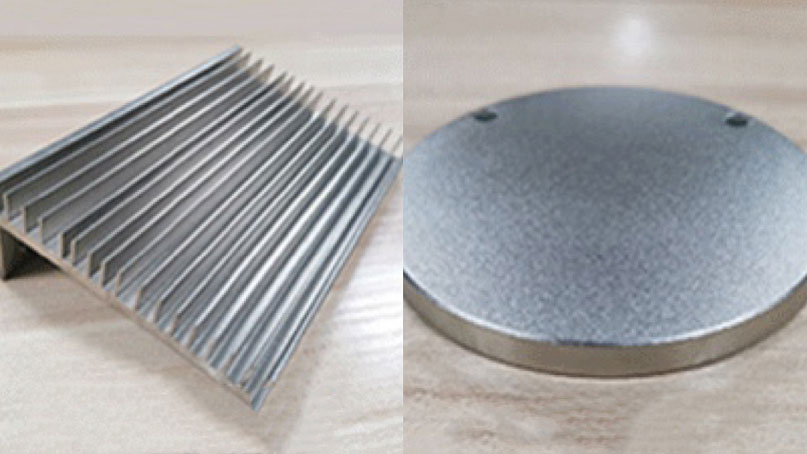

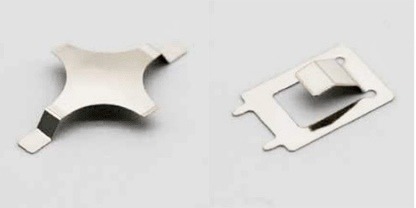

4. The electroless nickel layer is very uniform. As long as the plating solution can be soaked and the solute exchange is sufficient, the plating layer will be very uniform, and the electroless plating can almost achieve the effect of profiling. Electroplating cannot coat the full surface of some complex-shaped workpieces, but electroless plating can be used to coat workpieces of any shape.

5. The bonding force of the electroless plating layer is generally higher than that of the electroplating layer.

The difference between electroless plating and electroplating has been introduced above. In addition to these two surface treatment processes, JTR can provide a variety of surface treatment processes. For example spraying, first-class anodizing service, and so on. We can provide mold production, and batch parts production services, and can choose CNC machining, stamping, sheet metal, injection molding, and various processes according to specific needs. If you have related needs or want to know more, please feel free to contact us.