In CNC machining, not every part delivers the same value for money. For procurement teams, engineers, and project managers, the key question isn’t simply “What’s cheapest?” but:

✅ Which parts give me reliable performance without overpaying?

✅ How do material, complexity, and order size affect price?

✅ Which parts avoid hidden machining or post-processing costs?

This article provides clear, practical insights—not vague guides or empty buzzwords—so you can make smarter CNC purchasing decisions.

What Actually Determines CNC Part Cost-Effectiveness?

| Factor | What It Means | Cost Impact |

| Material Choice | Different metals or plastics vary in cost, strength, machinability | Wrong materials = higher machining time, waste |

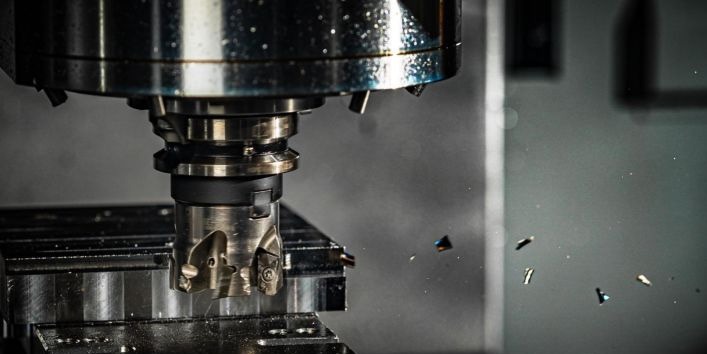

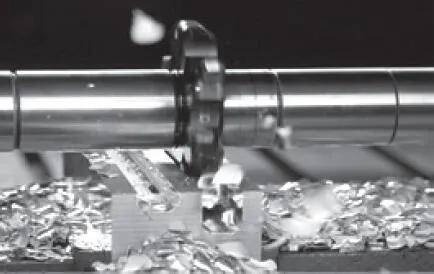

| Part Geometry | Complex shapes require more time and resources | Overly complicated designs drive up price |

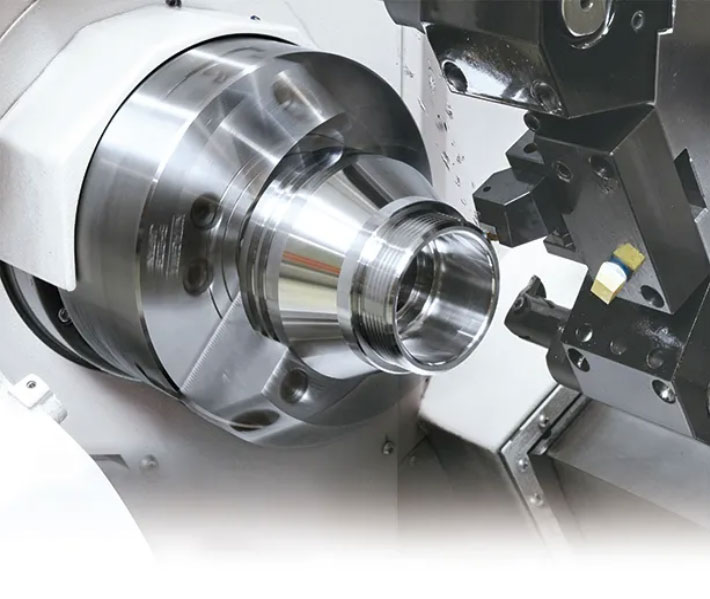

| Tolerances Required | Tighter tolerances mean slower machining, special tools | Excessive precision adds cost unnecessarily |

| Order Volume | More units lower the per-part price | Small batches increase setup and labor costs |

Bottom Line: Cost-effective parts are engineered, not improvised. Proper planning can slash prices without sacrificing quality.

When to Pay Extra Attention to Cost and Design

Watch for these scenarios—they often lead to unnecessary costs if handled wrong:

✅ Custom parts for classic cars or discontinued products

✅ Low-volume prototypes where unit price spikes fast

✅ Parts facing extreme heat, pressure, or stress

✅ Medical devices or implants with strict safety standards

Real-World Example: Classic car owners often use CNC to recreate rare parts. The key is using materials that match the function—no need for aerospace-grade alloys if standard aluminum performs perfectly.

Which CNC Machined Parts Are Truly More Cost-Effective?

Different Application Needs, Different “Best Value” CNC Choices

Your project type dramatically affects what makes a CNC part cost-effective.

| Industry | High-Value CNC Strategies |

| Automotive | Use aluminum or engineering plastics for brackets, mounts, custom components |

| Aerospace | Balance weight reduction with strength; aluminum often preferred unless titanium is essential |

| Electronics | Lightweight enclosures and structural parts; plastics or thin-walled metals optimize cost |

| Medical | For implants or tools, prioritize precision and regulatory materials despite higher price |

Example: Using titanium unnecessarily in automotive parts adds costs with minimal real-world benefit. Aluminum often meets strength needs at lower prices.

Which CNC Materials Give the Most Value?

Choosing the right material is one of the biggest cost drivers:

| Material | Ideal For… | Why It Saves Money |

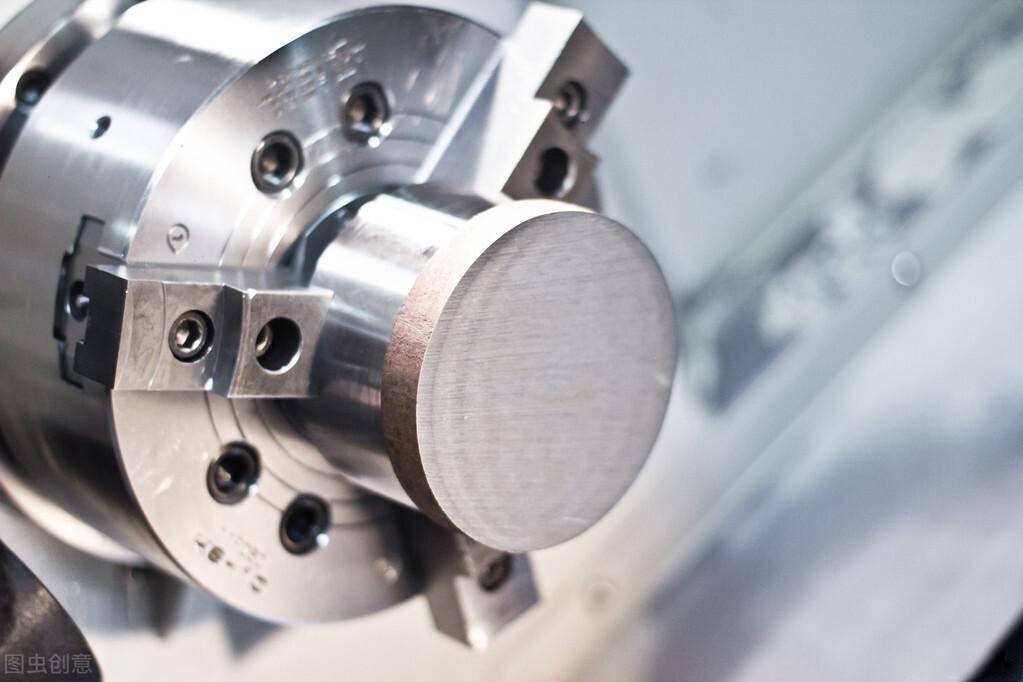

| Aluminum (6061, 7075) | Auto, aerospace, machine frames | Strong, light, easy to machine |

| Engineering Plastics (POM, Nylon, ABS) | Gears, housings, non-load parts | Low-cost, easy cutting, reliable for simple parts |

| Brass | Connectors, aesthetic parts, small fittings | Cuts cleanly, nice finish, low rework rate |

| Mild Steel | General structures, supports | Affordable, strong for everyday use |

| Titanium / Stainless | Extreme stress parts, medical implants | Only worth the price for critical parts |

Tip: Don’t overspend on premium materials if cheaper options do the job safely and reliably.

How Part Design, Tolerances, and Order Size Affect Costs

| Part Shape (Geometry) | Simple shapes = Faster, cheaper machining Complex curves, undercuts = More time, higher price |

| Precision (Tolerances) | ±0.01mm tolerances drive up time and tooling needs For non-critical parts, stick to standard ±0.1mm to save money |

| Order Volume | One-off prototypes = High per-part cost Larger batches = Lower price per piece |

Example: Simplifying a bracket’s design and avoiding tight tolerances can reduce costs by up to 40%.

How to Choose the Most Cost-Effective CNC Part

✅ Pick materials based on real use, not just “premium” labels

✅ Keep designs as simple as possible for your needs

✅ Only pay for tight tolerances when absolutely necessary

✅ Order in logical batch sizes—avoid small runs if possible

✅ Ask your CNC supplier how to optimize for lower costs early in the process

Avoiding Hidden CNC Costs

- Watch for these hidden cost drivers:

- Overly tight tolerances that require specialized tools

- Complex setups for under-optimized part shapes

- Expensive post-processing like polishing or coatings

- Small order quantities driving up per-part pricing

Conclusion

CNC machining delivers unbeatable flexibility, but maximizing value requires strategic choices—not vague promises or generic advice.

Whether you’re in aerospace, automotive, electronics, or medical fields, the most cost-effective CNC parts come from:

✔ Smart material selection

✔ Simplified part geometry

✔ Realistic tolerance decisions

✔ Optimized production volumes