How to Calculate CNC Machining Time?

From the most basic rule, the CNC machining time is similar to other times, that is the distance or length divided by the speed or rate. Combines the characteristics of machining processes, the general formula for CNC machining time calculation of turning, milling, facing and more operations is as below. The machining time here refers to cutting time.

T=L/f*N

N=1000*V/π*D

T=Machining Time

L=Length of cut in mm

N= rpm (revolution of the job per minute)

V=cutting speed in mpm (meters per minute)

D=diameter of the rod in mm

f= feed in mm/rev (millimeters per revolution)

CNC Milling Machining Time Calculation

CNC milling is a machining process can make slots or ribs of various sections, flat surface in vertical, horizontal and inclined planes, surfaces of revolution, helical grooves and more. For milling operations, the feed rate may be in per tooth, which means that you need to know the number of cutting edges, teeth, or flutes on the tool.

T (CNC milling machining time)

Finally, the T=L*No. Of passes/f*N=331.79*5/2*111.46=1658.95/222.92=7.44 minute.

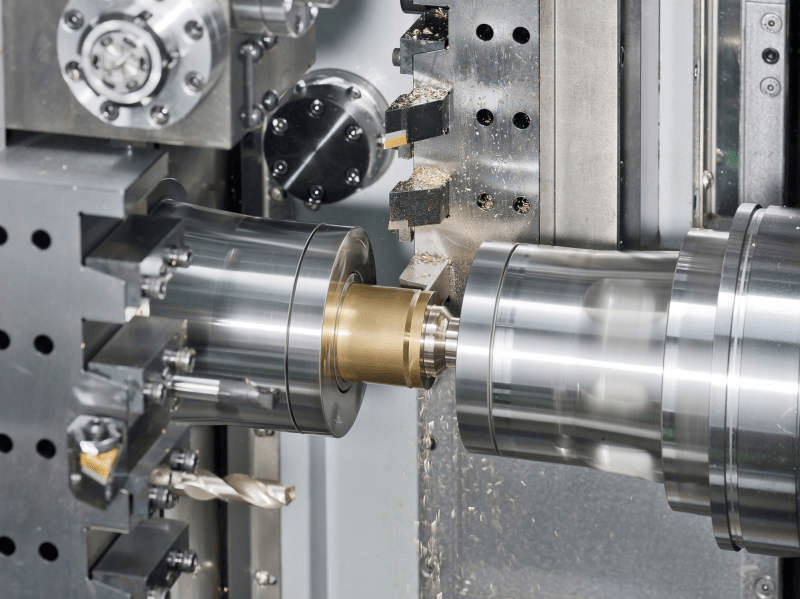

CNC Turning Machining Time Calculation

CNC Turning is a machining process in which producing turned parts by a single point tool on lathe machines. The cutting tool is fed either linearly in the direction parallel or perpendicular to the axis of rotation of the workpiece, or along a specified path to manufacture complex rotational shapes. The primary motion of cutting in turning is the rotation of the workpiece, and the secondary motion of cutting is the feed motion.

When calculating or estimating the CNC machining cycle time for the turning process, the formula is also based on

T=L/feed*N

The L or length=(tool approach+job length+tool over travels)*No. Of passes.

The N refers to average RPM, which is equal to 1000*cutting speed/π*average diameter.

2 Ways to Reduce CNC Machining Time

The machining auxiliary time of the machining center is the time for some indirect machining workpieces such as aligning the workpiece, tool setting time, tool changing time and so on. The time taken by these mechanical movements is called the machining auxiliary time. So how can we shorten the auxiliary time of the machining center? For the alignment and tool set of the workpiece, we can use the process positioning platform on the machining center. For tool change, we can choose some tool magazines with fast tool change speeds, such as the hat type tool magazine and the tool arm type tool magazine used on the machining center. Choosing the tool arm type tool magazine can save the tool change time.

The process positioning platform can save much auxiliary time

1) The process positioning platform eliminates the need for table alignment and tool set in the x and y directions when installing the workpiece. Compared with the traditional auxiliary operation, it can save about 90%-95% of the auxiliary time. The effective use rate of the machine tool has been increased from 57%-68% of the traditional auxiliary operation to 92%-96%. The cost of an expensive CNC milling machine and the depreciation of the processing center can also be reduced.

2) It can clamp many workpieces, especially the processing of small parts. The traditional workpiece clamping method must complete all the processing work according to the processing procedure after the workpiece is installed, while it cannot be replaced with other workpieces during the urgent processing. After the universal process positioning platform is adopted, as long as the workpiece or fixture positioning datum meets the requirements of the positioning platform, other workpieces that need to be processed can be replaced at any time for processing. After completion, locate and clamp the removed workpiece in the middle to resume processing.

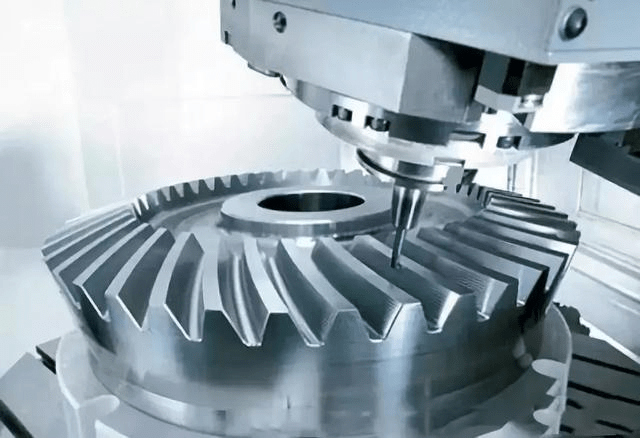

Type of tool magazine also matters processing speed

There are many different tool magazines of a machining center, such as a hat type, a knife arm type, a simultaneous type, a flying saucer type, etc. While ordinary vertical machining centers only use the hat type and the tool arm type. The tool-arm magazine can save 50% of the time compared with the hat-type tool magazine. It is more suitable to use the former one in mass production. The simultaneous-moving tool magazine and the flying saucer tool magazine are unique tool magazines for high-speed machining centers as well as drilling and tapping centers. The tool magazine of the high-speed machine tool also has a tool arm type tool magazine, and the tool changing the speed of these two tool magazines both are much.