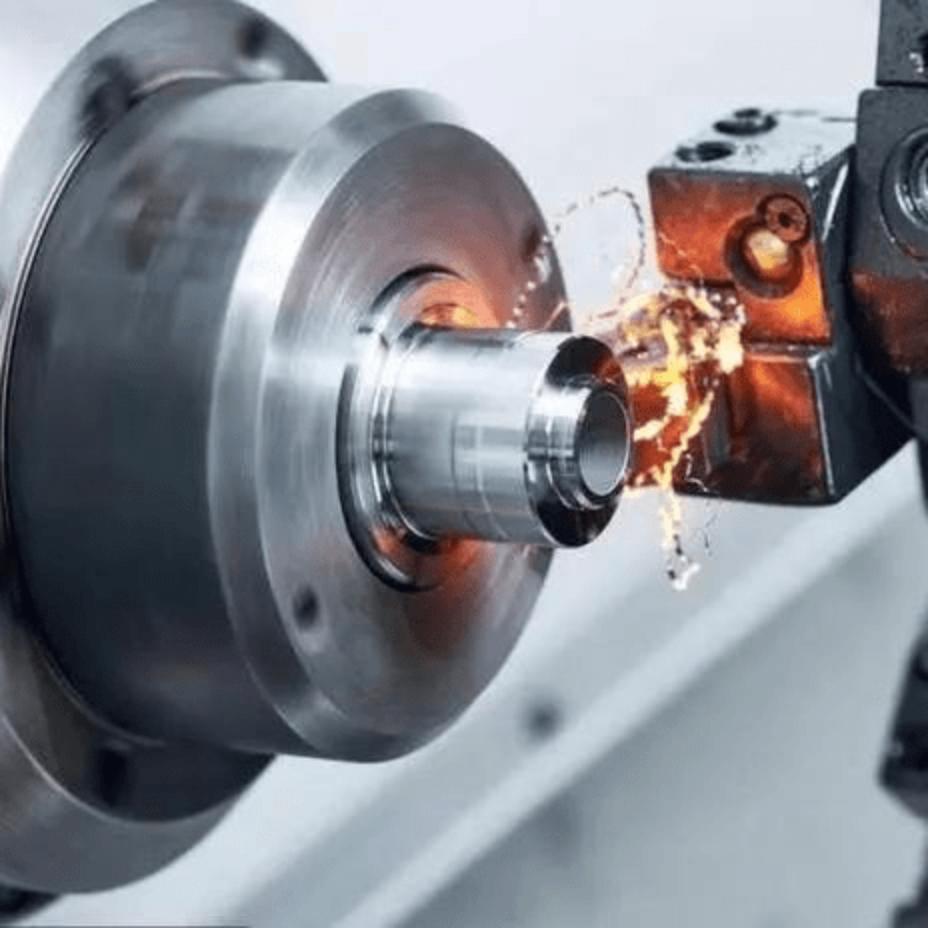

Precision, efficiency, and material versatility are critical in today’s manufacturing environment. CNC machining has emerged as an effective solution, providing a unique combination of these critical components. This article delves into the world of CNC machined parts, examining the benefits they bring to a variety of applications. We’ll then demonstrate the vast array of materials that can be precisely shaped using CNC machining, catering to a wide range of project requirements. Finally, we’ll introduce CNC machining manufacturer JTR and explain why we’re the best partner for your CNC machining needs.

Advantages of CNC Machining Parts

CNC machining offers numerous advantages over traditional machining methods. Here’s a breakdown of the key benefits that make CNC machined parts an appealing choice for a variety of applications:

- High Precision and Accuracy: CNC machines use computer-controlled tools to manufacture parts with high dimensional accuracy and repeatability. This is critical for applications requiring tight tolerances and precise functionality.

- Improved Part Complexity: CNC machining can handle complex geometries and intricate features that manual machining cannot. This enables innovative designs and parts with increased functionality.

- Enhanced Repeatability: CNC programs ensure consistent part production, ensuring that each machined component is identical to the previous one. This level of repeatability is required to ensure consistent product quality in high-volume manufacturing.

- Material Versatility: CNC machines can work with various materials, such as metals, plastics, and composites. This versatility allows you to choose the best material for your application based on strength, weight, corrosion resistance, or other desired properties.

- Reduced Waste: CNC machining reduces material waste compared to traditional methods. The computer-controlled tools precisely remove material while leaving little scrap. This translates to cost savings and a lower environmental impact.

- Increased Production Efficiency: Automation and computer control allow CNC machines to run continuously with minimal setup time. This results in faster production cycles and higher output than manual machining.

- Improved Surface Finish: CNC machining can produce parts with superior surface finishes that are smooth and consistent, requiring little post-processing. This can improve the appearance, functionality, and performance of the components.

- Design Flexibility: CNC machining allows for rapid design iterations and program modifications. This flexibility allows for more efficient prototyping and product development cycles.

- Reduced Labor Costs: CNC machining automates machining tasks, reducing the need for manual labor. This can result in significant long-term cost savings, particularly in high-volume production.

- Improved Safety: CNC machines reduce the risk of operator error and injuries that come with manual machining processes. The computer-controlled operation keeps workers safe from moving parts and sharp tools.

The benefits of CNC machined parts make them an invaluable asset in a variety of industries. CNC machining provides a compelling solution for producing high-quality, complex parts across a wide range of applications, thanks to superior precision and repeatability, as well as material versatility and production efficiency.

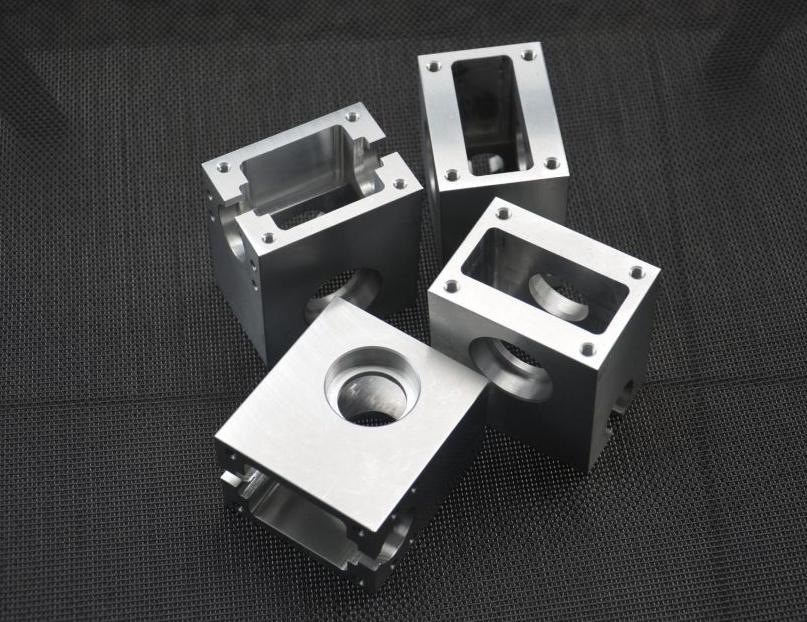

Different CNC Machining Parts

CNC machining is a versatile process that can work with a variety of materials. Here’s a breakdown of some commonly used materials and their key properties.

| Material | Properties | Applications |

| CNC Machining Aluminum Parts | Lightweight Ductile Good machinability Excellent corrosion resistance | Aerospace components Automotive parts Electronics enclosures Medical devices Consumer goods |

| CNC Machining Steel Parts | High strength Durable Wide range of alloy options Magnetic properties (depending on the alloy) | Machine components Gears and shafts Tools and dies Construction equipment Heavy machinery |

| CNC Machining Stainless Steel Parts | High strength Excellent corrosion resistance Good machinability (some grades) Hygienic | Medical instruments Food processing equipment Chemical processing equipment Marine hardware Architectural components |

| CNC Machining Brass and Copper Parts | Excellent electrical conductivity Good heat conductivity Malleable and ductile Aesthetic appeal | Electrical connectors Plumbing fittings Heat sinks Decorative parts Musical instruments |

| CNC Machining Titanium Parts | High strength-to-weight ratio Excellent corrosion resistance Biocompatible High melting point | Aerospace components Medical implants High-performance automotive parts Sporting goods Military equipment |

| CNC Machining Plastic Parts | Lightweight Wide variety of properties (strength, flexibility, heat resistance) Cost-effective Can be molded into complex shapes | Prototypes Consumer goods Gears and cams Electrical insulators Medical devices |

Why Choose JTR for Your CNC Machining Parts?

1. Experience and Capabilities

Different materials have distinct machining properties, and JTR with experience in your desired material will be more familiar with the best cutting parameters, tooling, and techniques for producing high-quality results. Consider the complexity of the parts you need machined. As a professional CNC machining manufacturer with experience dealing with complex geometries and tight tolerances, we will be better equipped to manage your project.

2. Quality Control Procedures

JTR has a clearly defined quality management system in place. This system should define its procedures for inspecting parts throughout the manufacturing process to ensure that they meet your dimensional specifications and quality requirements.

3. Customer Service and Communication

JTR responds to your inquiries and communicates clearly throughout the project. Clear and timely communication is essential for understanding your needs and promptly addressing any questions or concerns. We are a company that provides regular updates on your project’s progress, keeps you informed of any potential challenges, and actively seeks your input or approval when necessary.

Conclusion

Manufacturers can achieve exceptional results by leveraging the numerous benefits of CNC machining as well as the wide range of machinable materials. JTR as a professional CNC machining parts manufacturer in China with its commitment to precision, quality, and exceptional customer service, positions itself as the ideal partner for bringing your CNC machining requirements to life. We have the necessary experience, capabilities, and dedication to deliver high-quality parts on time and within budget. Whether you require complex prototypes, intricate components, or high-volume production runs, JTR is here to help you succeed in manufacturing. So, if you need a dependable and trustworthy CNC machining partner, look no further than JTR. Contact us today to discuss your project and see how we can make your vision a reality.