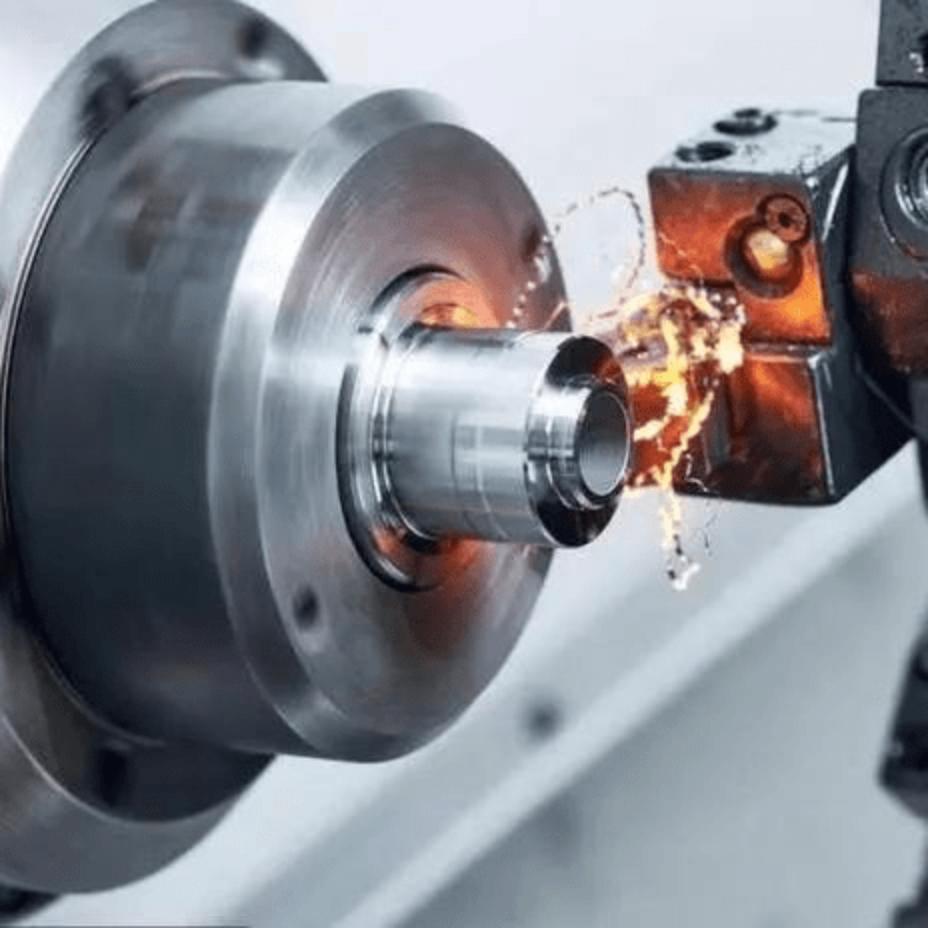

CNC machining is becoming the preferred method for producing strong, complex parts, and its use with stainless steel is growing. Strong, resistant to corrosion, and having a sleek appearance, this adaptable metal is a dream material for a wide range of uses. However, before you start working on your next masterpiece made of stainless steel, we must ask you this important question: Does the design of parts for CNC machining stainless steel have any restrictions?

It is not intended to stifle creativity to accept these limitations. It’s about creating a link between your aspirations and reality so that your masterpiece made of stainless steel comes out of the machine not only gorgeous but also perfectly working. Come along with us as we investigate the limits of CNC machining and reveal the unspoken restrictions that influence each marvel of sculpture.

What Are the Material and Design Limitations to Designing CNC Machining Stainless Steel Parts?

Material Properties:

- Hardness and strength: Compared to softer metals like aluminum, stainless steel is more difficult to machine because of its relative strength and hardness. In addition to limiting the kinds of tools and methods that can be employed, this can also result in longer machining times and more tool wear.

- Thermal expansion: Temperature variations cause stainless steel to expand and contract. This can result in finished parts warping or having dimensional errors, particularly in complex or large designs. To guarantee that parts retain the appropriate shape and fit, design decisions must consider this attribute.

- Internal stresses: Because the material is released from the bulk during machining, stainless steel is susceptible to internal stresses. This can cause distortion or cracking, especially in areas with thin walls or sharp corners. These stresses can be reduced with careful design considerations.

Design Complexity:

- Internal features and geometries: Using conventional CNC tools to machine intricate internal features like channels, cavities, or undercuts can be challenging or impossible. These features add to the cost and complexity by requiring additional machining steps or specialized tooling.

- Thin walls: During machining, thin walls may deflect and vibrate a lot, which could result in incorrect dimensions or problems with surface finish. Sufficient wall thickness must be maintained to guarantee part stability and strength.

- Sharp corners: Sharp corners can produce weak spots in the part and be difficult to reach with ordinary tools. It is usually preferred to have rounded transitions or fillets to increase strength and machinability.

- Large flat surfaces: Internal stresses released during machining can cause large flat surfaces to warp. This can be avoided by breaking these surfaces up into smaller panels or by including ribs for support.

How to Overcome Limitations to Designing CNC Machining Stainless Steel Parts?

Design for Manufacturability (DFM):

It all comes down to comprehending the material and process and then designing your design to be machined effectively and efficiently. Consider it similar to pre-heating your component for a CNC machine: the proper features, thickness, and complexity guarantee that the part emerges flawlessly, unburned, or undercooked. Reduce complexity to save money and headaches, select features that work well with the tools, and optimize wall thickness for strength without wasting any.

Collaboration with Machinists:

First, machinists with extensive experience are well-versed in both the material and the procedure. They can spot possible flaws in your design that you might not be aware of. Sharp corners, for instance, can be challenging to machine and increase the risk of tool breakage. More machinable design features can be suggested by skilled machinists.

Second, skilled machinists can assist you in making your design as manufacturable as possible. They can suggest the best instruments and methods for the job at hand. They can also assist you in finding ways to cut expenses and complexity.

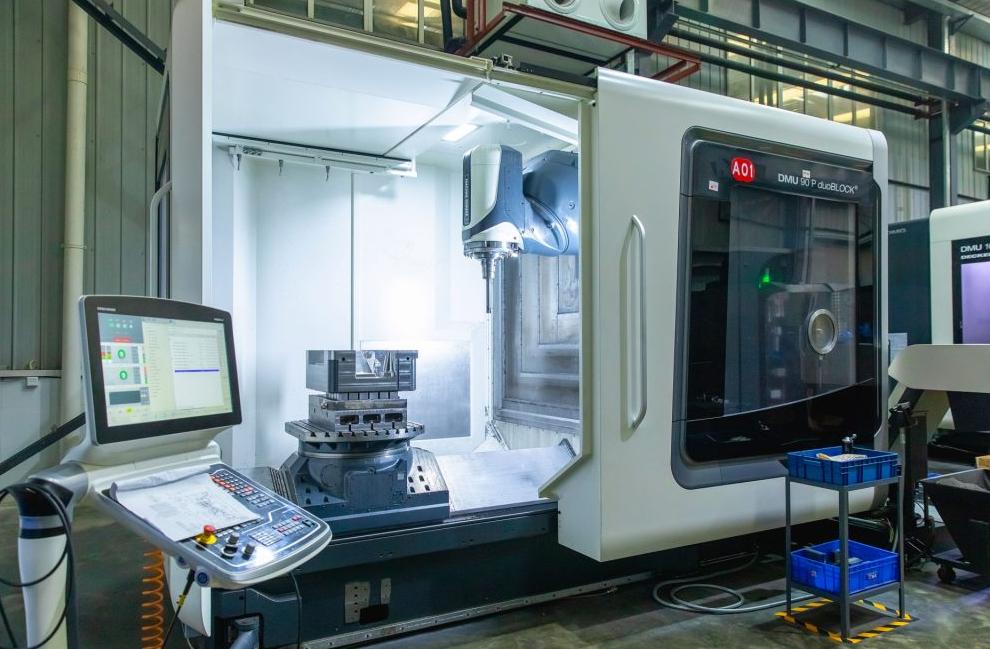

JTR offers a dependable one-stop CNC machining service that includes associated machining services for small, medium, and large-sized parts as well as quick prototyping part production in a range of materials. Welcome to contact us.

Prototyping and Iteration:

First, you can test your design and find any potential flaws with prototyping. For instance, you might discover that using your current tools to machine a sharp corner or access an internal feature is impossible. Before you commit to machining a large number of parts, prototyping can help you find these problems early in the design process.

Second, iteration helps you to improve the quality of your parts and refine your design. For instance, altering a feature’s design might enable you to increase the parts’ sturdiness or strength. You can find these chances and adjust your design as needed with the aid of prototyping and iteration.

What Are the Benefits within Limitations to Designing CNC Machining Stainless Steel Parts?

When constraints push designers to think creatively, they can spur efficiency and innovation in the CNC machining stainless steel parts. For instance, machine cutting sharp corners may be challenging due to the strength and hardness of stainless steel. Because of this, designers may decide to investigate alternate layouts that make use of fillets or rounded edges. In addition to increasing the part’s strength and durability, these designs may be easier to machine.

In CNC machining designs, it is important to strike a balance between practicality and complexity because this can result in parts that are both aesthetically pleasing and functional. For instance, a part’s correct operation might require a sophisticated internal feature. But, if the feature is overly complicated, it might be hard or impossible to machine. In this situation, the featured designer might need to make it simpler or come up with an alternate method to accomplish the same goal.

Conclusion

Recognizing the limitations of CNC machining stainless steel empowers creativity instead of stifling it. It offers a structure that lets you push boundaries without getting into trouble. You can fully realize the potential of CNC machining and produce beautiful, flawlessly functioning stainless steel parts by accepting these limitations and utilizing them constructively.