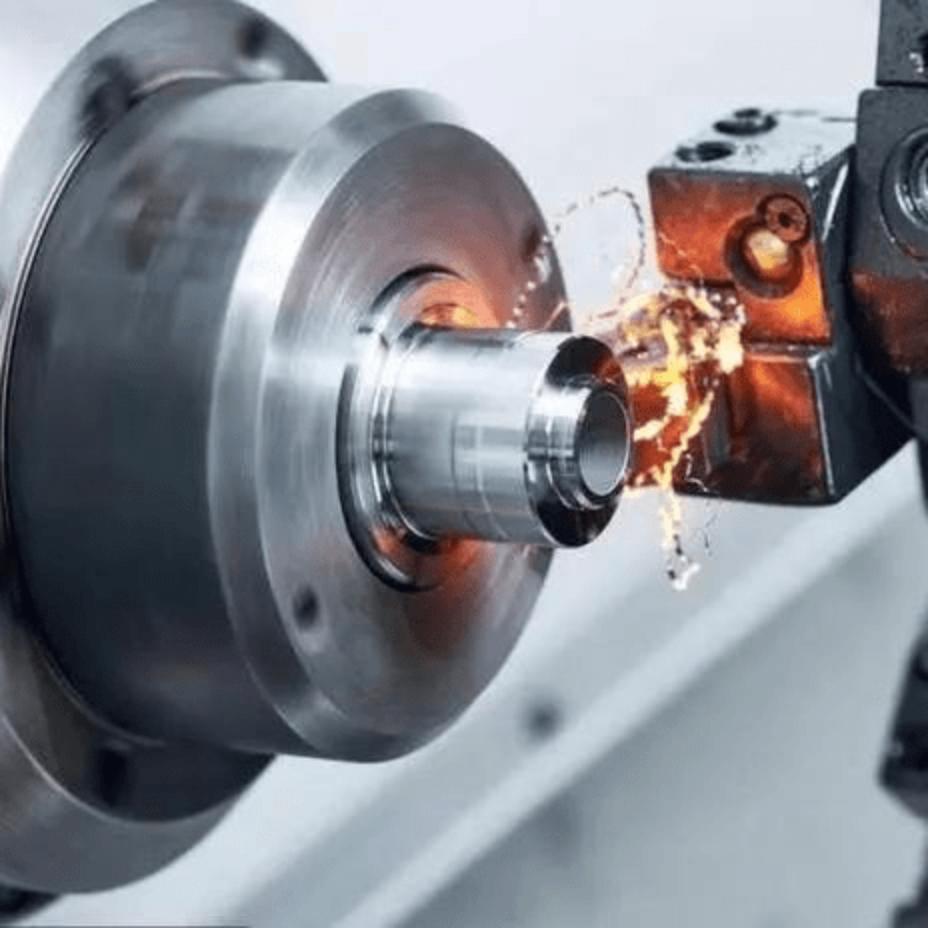

CNC machining is a cornerstone in the manufacturing industry, demonstrating the marriage of efficiency and precision. Stainless steel is the most widely used material in CNC machining due to its exceptional durability and adaptability. Because of its inherent strength and resistance to corrosion and wear, it’s the perfect material for a wide range of applications. This article explores the many benefits of using CNC machining to create stainless steel parts and reveals the relationship between this material and this method. We’ll look at how stainless steel can be fully utilized by CNC machining to create parts with remarkable accuracy, adaptability, efficiency, and surface finish.

Benefit 1: Precision and Accuracy

Stainless steel parts with outstanding dimensional tolerances can be produced thanks to CNC machining’s exceptional precision and accuracy. This is made possible by the computer numerical control (CNC) system, which carefully directs the machining operation to produce repeatable and consistent results.

CNC machining ensures that every part meets the exact specifications specified in the CAD design by eliminating human error and inconsistencies, in contrast to traditional manual machining methods. In many industries, including aerospace, medical, and automotive, where even small deviations can have serious repercussions, precision is crucial.

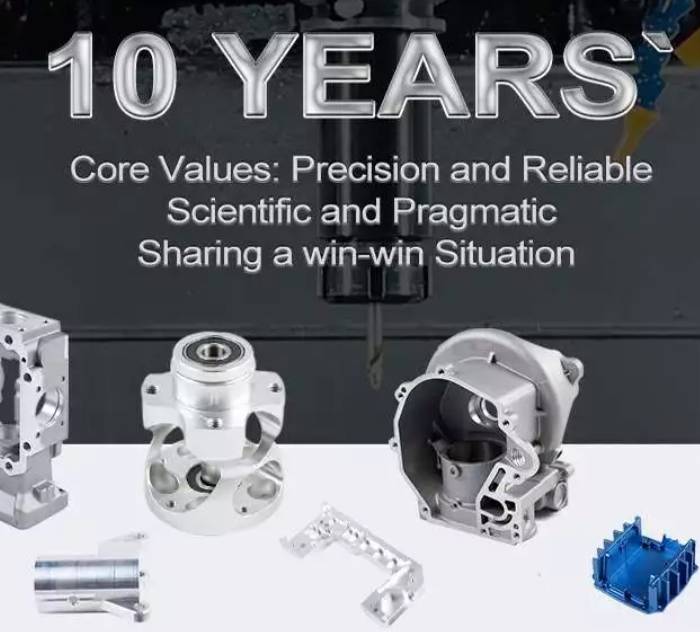

Benefit 2: Versatility and Customization

- CNC machining can produce a wide range of stainless steel parts, from simple to complex designs. This is so that intricate features and geometries can be created using computer-aided design (CAD) files, which are used to program CNC machines. Therefore, parts for a wide range of applications, such as consumer goods, automotive, aerospace, and medical, can be produced using CNC machining.

- CNC machining allows for the customization of stainless steel parts. This implies that parts can be customized to fit particular needs and uses. For instance, parts with various surface finishes, tolerances, and dimensions can be produced via CNC machining. Forging and casting are two examples of manufacturing processes that cannot provide this degree of customization.

- CNC machining can produce small batches of stainless steel parts efficiently. This is a result of CNC machines’ ability to be programmed to produce parts precisely and quickly. Consequently, low-volume production and prototyping benefit greatly from CNC machining.

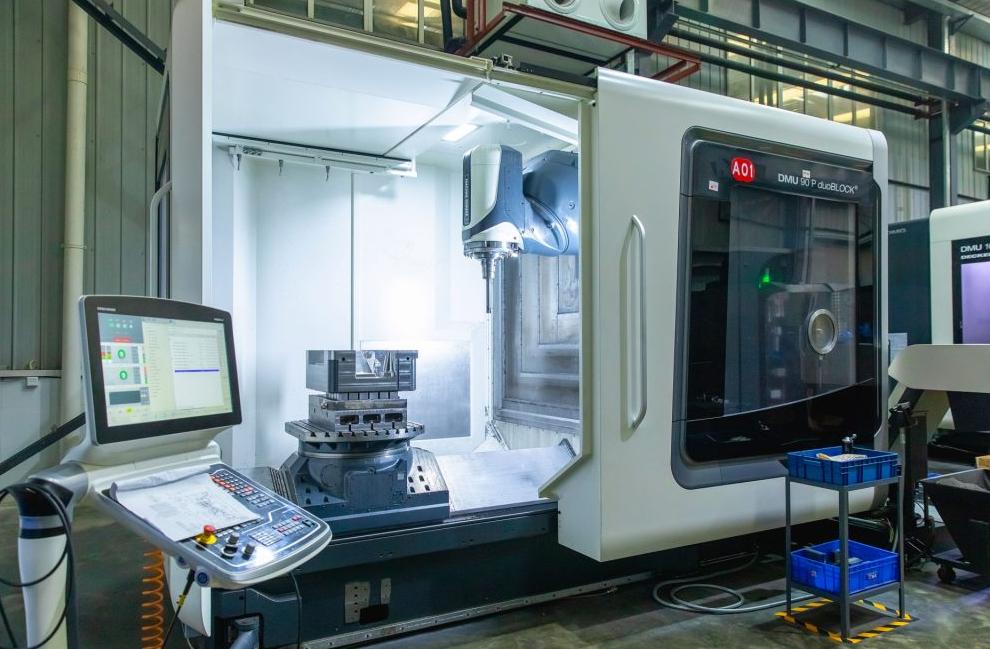

Benefit 3: Efficiency and Productivity

CNC machining stands out as a highly efficient and productive method for creating stainless steel parts due to its inherent characteristics and the advantages it offers over traditional manufacturing techniques. Let’s delve into the factors that contribute to its efficiency and productivity:

- Automated Processes and Computer Control: CNC machining is highly automated, requiring no human intervention and lowering the possibility of human error. Repeatable and consistent part production is ensured by the precise guidance of the machining process provided by computer numerical control (CNC). By reducing downtime and increasing output, this automation optimizes operations.

- Optimized Tool Paths and Rapid Cutting Speeds: CNC machining makes it possible to optimize tool paths, making sure that the cutting tools follow the most effective paths to produce the required part features. This optimization cuts down on pointless tool movements and speeds up the machining process. High cutting speeds are another capability of CNC machines that boost production effectiveness.

- Unattended Machining and Multi-Axis Capabilities: CNC machines can run for prolonged periods without human supervision, enabling production to continue even during off-peak hours or shifts. This capacity boosts overall productivity by extending the production period.

- Reduced Material Waste and Improved Sustainability: CNC machining reduces waste material by carefully cutting away the material that is required to form the desired part features. The economical and sustainable use of resources is enhanced by this effective material utilization.

Benefit 4: Surface Finish and Quality

Surface quality and finish are two of the many advantages that CNC machining provides when producing stainless steel parts. Examining “Surface Finish and Quality” in more detail will show you why CNC machining is a wise decision when it comes to stainless steel parts:

- Enhanced Aesthetics and Visual Appeal: Stainless steel parts can have a variety of surface finishes produced by manufacturers thanks to CNC machining, which accommodates a wide range of aesthetic preferences. CNC machining can create parts with mirror-like polishes and finely textured patterns that are both elegant and sophisticated, while also meeting functional requirements.

- Improved Functionality and Performance: Stainless steel parts’ functionality and performance are greatly influenced by their surface finish. part longevity and efficiency are increased when there is less wear and friction due to a smooth, consistent finish. Furthermore, a precisely defined surface can maximize heat transfer and fluid flow, two important factors in many applications.

- Corrosion Resistance and Durability: One of stainless steel’s most valued characteristics is its remarkable corrosion resistance. Its resistance to harsh environments, however, can be greatly affected by the surface finish. By guaranteeing a consistent and faultless finish, CNC machining preserves the integrity of stainless steel and lengthens its service life.

- Compliance with Industry Standards: There are strict requirements for surface finish in many different industries, especially those that deal with sensitive applications like medical devices and food processing equipment. The highest standards of quality and safety are consistently met by stainless steel parts made via CNC machining.

Conclusion

Precision, versatility, efficiency, and surface finish are all important requirements for high-quality stainless steel parts, and CNC machining is a powerful tool to meet these needs. It gives producers the ability to create robust, beautiful, and useful parts for a variety of uses. It is crucial to consider the benefits and drawbacks of every option when deciding which manufacturing process is best for producing stainless steel parts. A variety of applications find CNC machining to be an appealing option due to its exceptional combination of accuracy, adaptability, efficiency, and surface finish. JTR is a good option if you’re looking for a manufacturer who can provide you with excellent CNC machining service.