CNC turning is a versatile process that can be used to produce a wide variety of parts. However, traditional turning methods can be limited in terms of accuracy, productivity, and flexibility. Advanced techniques in CNC turning can help to overcome these limitations and improve the quality, efficiency, and versatility of CNC turning operations. Here we will focus on the frequently used advanced techniques in CNC Turning and find the benefits compared to traditional turning methods.

What are the Advanced Techniques in CNC Turning?

There are several advanced techniques that can be used to improve the quality, accuracy, and efficiency of CNC turning.

- 5-axis turning: This technique allows the cutting tool to move in five axes, which gives the CNC machine the ability to machine complex shapes with a single setup. This can save time and improve accuracy. For example, a 5-axis CNC lathe can be used to machine a part with a helical groove or a freeform surface.

- Live tooling: This technique allows the cutting tool to be changed or adjusted while the machine is still running. This can save time and improve productivity. For example, live tooling can be used to machine threads on a part without having to stop the machine and change tools.

- Thread milling: This technique is used to machine threads on a workpiece. It is a more accurate and efficient way to machine threads than traditional methods. Thread milling uses a special tool that has multiple cutting edges, which allows it to machine the thread in a single pass.

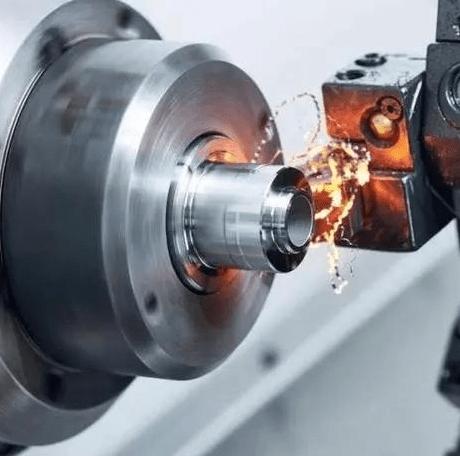

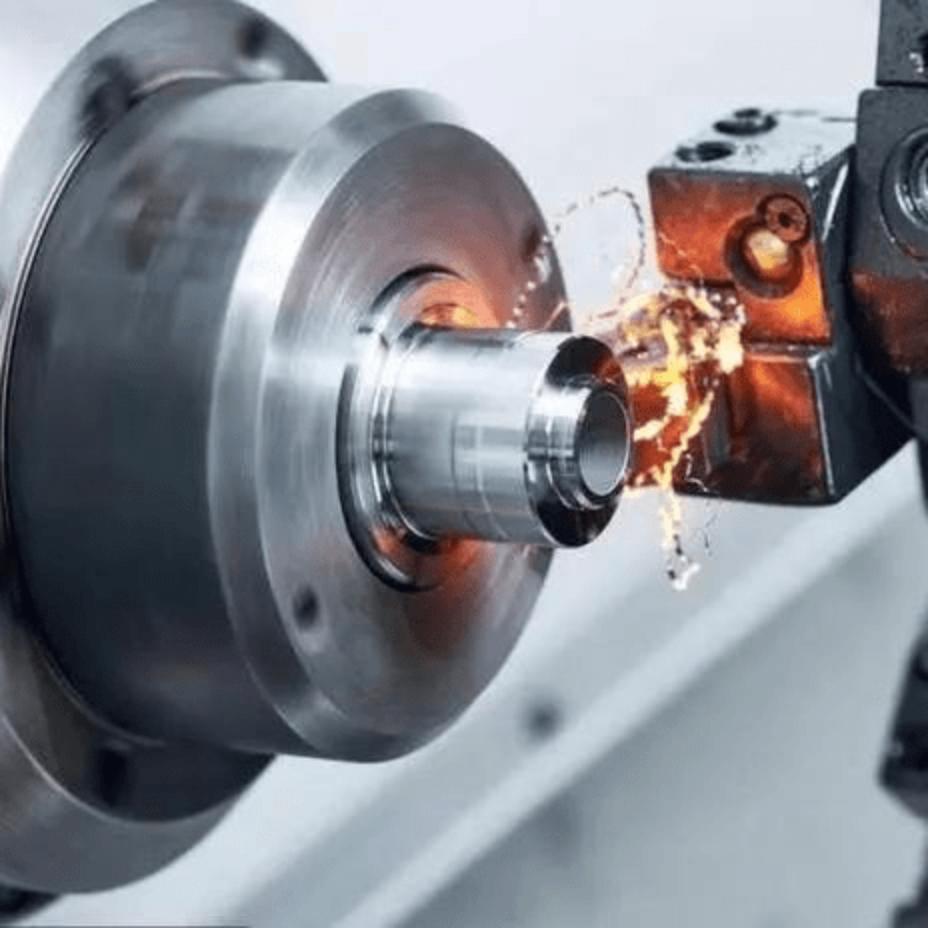

- Hard turning: This technique is used to machine hardened steels and other difficult-to-machine materials. It uses special cutting tools and techniques to achieve high accuracy and surface finish. Hard turning uses high-pressure coolant to cool the cutting tool and the workpiece, which helps to prevent the tool from wearing out prematurely.

- High-speed machining: This technique uses high spindle speeds and feed rates to machine parts quickly. It is a good choice for high-volume production applications. High-speed machining uses special cutting tools that are made from high-speed steel or carbide.

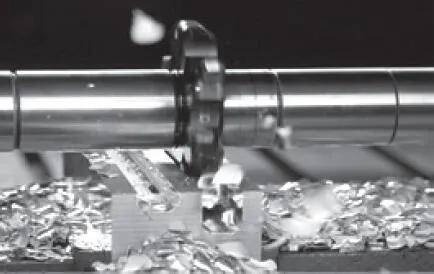

- Multitasking machining: This technique allows multiple machining operations to be performed on the same machine at the same time. This can save time and improve productivity. Multitasking machining can be used to machine a part in a single setup, which eliminates the need to move the part between machines.

What are the Benefits of Using Advanced Techniques in CNC Turning?

Here are some of the benefits of using advanced techniques in CNC turning compared to traditional techniques:

- Improved accuracy and surface finish: Advanced techniques can be used to achieve higher accuracy and surface finish than traditional methods. This is important for parts that require tight tolerances or a smooth surface finish.

- Increased productivity: Advanced techniques can help to reduce machining time and improve throughput. This can be a major benefit for high-volume production applications.

- Reduced costs: Advanced techniques can help to reduce material waste and tool wear. This can save money in the long run.

- Increased flexibility: Advanced techniques can be used to machine complex shapes and difficult-to-machine materials. This gives manufacturers more design freedom and allows them to produce a wider range of parts.

- Improved safety: Advanced techniques can help to improve safety in the workplace by reducing the need for manual intervention. This is important for reducing the risk of accidents and injuries.

How to Use Advanced Techniques in CNC Turning to Achieve High-quality Results?

Here are some additional tips that may be specific to certain advanced techniques:

- For 5-axis turning, it is important to use a machine that has the right capabilities for the job. The machine should have the necessary axes of motion and the ability to control the cutting tool accurately.

- For live tooling, it is important to use tools that are designed for the specific application. The tools should be strong enough to withstand the forces of cutting and should be able to handle the required cutting parameters.

- For thread milling, it is important to use a tool that has the correct number of flutes and the correct geometry for the thread size. The tool should also be made from a material that is resistant to wear.

- For hard turning, it is important to use a cutting tool that is made from a material that is hard enough to withstand the heat and forces of cutting. The tool should also be coated with a material that is resistant to wear.

- For high-speed machining, it is important to use a cutting tool that is made from a material that is strong enough to withstand high cutting speeds. The tool should also be coated with a material that is resistant to heat and wear.

- For multitasking machining, it is important to use a machine that has the right capabilities for the job. The machine should have the necessary axes of motion and the ability to control multiple cutting tools simultaneously.

By following these tips, you can use advanced techniques in CNC turning to achieve high-quality results for a wide variety of applications.

JTR offers a wide range of CNC turning services, and we are committed to providing our customers with the highest quality products and services. Our team of experienced engineers will work with you to develop a perfect turning plan that meets your specific needs.