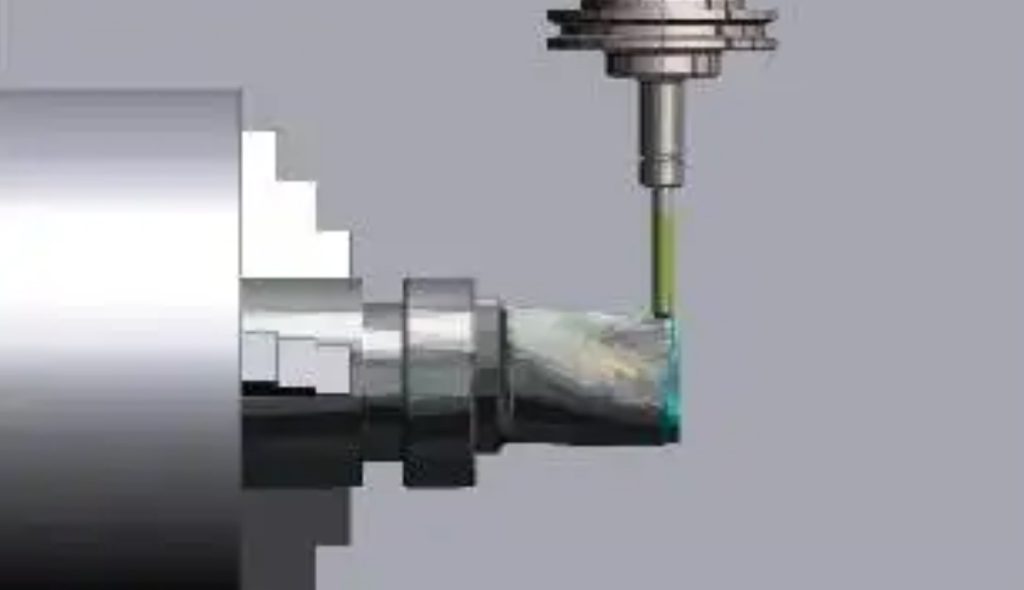

Businesses are continuously looking for creative ways to differentiate their products and satisfy the ever-changing needs of their customers in today’s dynamic and competitive marketplace. With its revolutionary ability to revolutionize both product design and manufacturing, computer numerical control (CNC) milling is enabling businesses to produce innovative products with unmatched precision, flexibility, and customization. In the subtractive manufacturing process known as CNC milling, materials are precisely shaped and sculpted using computer-controlled cutting tools. CNC milling, in contrast to conventional manual machining techniques, offers a degree of accuracy and repeatability that is just not possible for human hands to achieve. Due to its accuracy, previously unachievable complex and intricate geometries can now be created.

How Does CNC Milling Contribute to Product Innovation and Design Flexibility?

A rotating cutting tool is used in CNC milling, a computer-controlled subtractive manufacturing technique, to remove material from a workpiece. It is a strong and adaptable tool that can be used to make a broad range of products, from basic prototypes to intricate final products. CNC milling contributes to product innovation and design flexibility in several ways:

- Rapid prototyping: Prototypes of new products can be produced quickly by CNC milling machines, enabling designers to test their ideas and make necessary adjustments before moving forward with production. In addition to saving money and time, this can guarantee high-quality products.

- Complex geometries: Complex geometries that would be difficult or impossible to produce using conventional methods can be created by CNC milling machines. This makes it possible for designers to produce more useful and inventive goods.

- Precision and accuracy: CNC milling machines are highly accurate and precise, enabling them to produce products with a high level of detail. For products that require precision, like aerospace components and medical devices, this is crucial.

- Customization: Customized products can be made with CNC milling machines. This is crucial for goods like orthotics and prosthetics that must be customized to meet the needs of each user.

A useful tool for manufacturing and product development is CNC milling. It can assist companies in developing inventive and adaptable products that satisfy their clientele’s demands.

What Specific Examples Can You Provide of How CNC Milling Has Been Used to Create Innovative Products?

Sure, here are some specific examples of how CNC milling has been used to create innovative products:

Medical Devices

- Custom Prosthetic Limbs: The production of prosthetic limbs has been transformed by CNC milling, which makes it possible to create exact, personalized designs that suit each person’s specific requirements and body type. Amputees can now regain their independence and mobility with previously unheard-of levels of comfort and functionality thanks to technology.

- Implantable Devices: The production of implantable devices, including pacemakers, dental implants, and joint replacements, depends heavily on CNC milling. These devices can be safely implanted into the human body because of the precision and accuracy of CNC milling, which guarantees that they meet strict medical standards.

Aerospace and Automotive Industries

- Lightweight Aircraft Components: Producing strong and lightweight aircraft parts like wings, fuselages, and engine parts requires the use of CNC milling. Utilizing CNC milling to produce complex, high-strength parts enhances an aircraft’s overall performance and fuel efficiency.

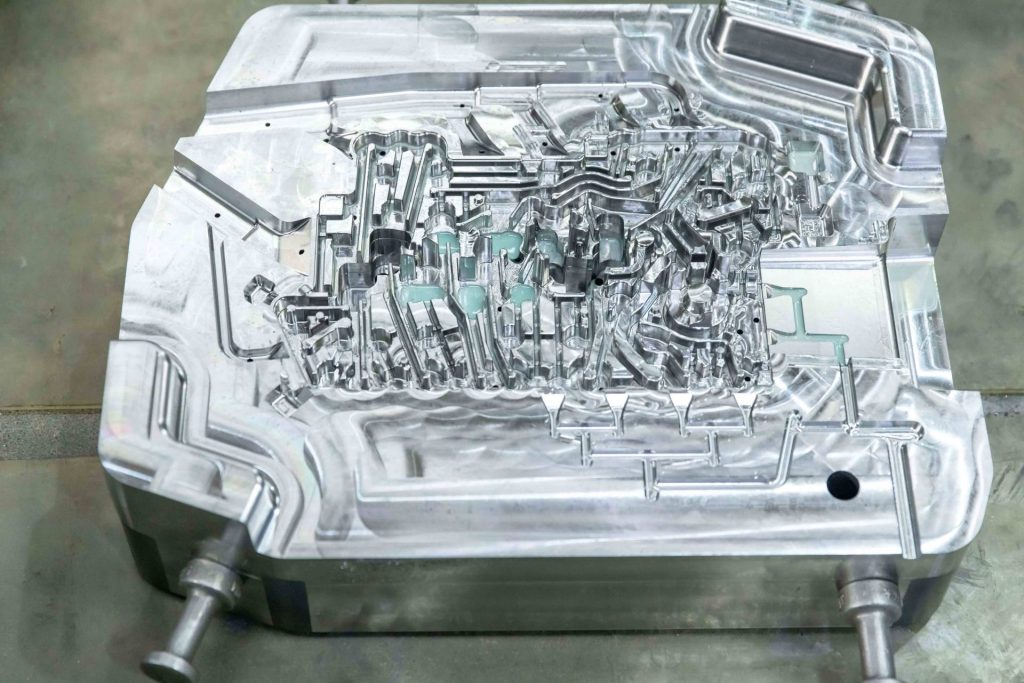

- Automotive Engine Components: The automotive industry uses CNC milling a lot to make intricate and accurate engine parts like intake manifolds, cylinder heads, and pistons. These components are guaranteed to meet the strict performance and reliability standards of contemporary engines thanks to the accuracy of CNC milling.

Consumer Goods

- Customized Mobile Devices: Customized back covers, accessories, and cases for mobile devices are made using CNC milling. People can now add distinctive patterns and designs to personalize their gadgets.

- Complex Sports Equipment: Bicycle frames, baseball bats, and golf clubs are just a few examples of the lightweight, intricate sports equipment made possible by CNC milling. Professional and amateur athletes alike can benefit from these products’ improved performance and durability thanks to this technology.

Creative Industries

- Architectural Models: Architects and designers can more clearly and precisely visualize and communicate their design concepts thanks to the precise and detailed architectural models produced by CNC milling.

- Sculptures and Artworks: As a useful tool for artists and sculptors, CNC milling enables them to produce elaborate and complex sculptures from a range of materials, including stone, metal, and wood.

These instances highlight the inventive and varied uses of CNC milling in a range of sectors. CNC milling is expected to become even more important in the future as technology develops, influencing both product design and manufacturing.

How Can CNC Milling Be Used to Personalize and Customize Products for Individual Consumers?

The process of personalizing and customizing products for individual customers has been transformed by CNC milling. It provides a level of repeatability, flexibility, and precision that is not possible with conventional manufacturing techniques. Here are some specific ways CNC milling is used for personalization and customization:

- Rapid prototyping: With CNC milling, designers can quickly produce prototypes of customized products, which helps them to improve the design and make sure the final product fits the needs of the customer. This iterative procedure shortens lead times and simplifies the customization process.

- Precision and accuracy: CNC milling machines possess the ability to produce products with an exceptional level of accuracy and precision. This is necessary to make precisely fitted customized items like dental implants, prosthetic limbs, and jewelry.

- Complex geometries: It would be difficult or impossible to create complex geometries and intricate details using traditional methods, but CNC milling can do it. This creates a plethora of opportunities for customized goods by enabling designers to use distinctive patterns, engravings, and designs.

- Material versatility: A large variety of materials, such as metals, polymers, wood, and composites, can be processed using CNC milling. Because of its adaptability, a range of materials can be used to create customized products that suit various tastes and aesthetics.

- Automation and scalability: Computer-aided design (CAD) software can be integrated and automated with CNC milling machines to facilitate the efficient production of customized products through mass customization.

Conclusion

CNC milling has emerged as a key driver of product innovation and customization, providing companies with an effective tool to design products that are not only inventive and efficient but also customized to meet the specific requirements and tastes of individual customers. With the ongoing advancements in technology, CNC milling is expected to become increasingly significant in the future of product design and manufacturing, bringing about a period of unparalleled customization, innovation, and efficiency. Chongqing Jin Te Rui Machine Co., Ltd. is an expert manufacturer dedicated to providing CNC milling service. Contact us if you would like more details.