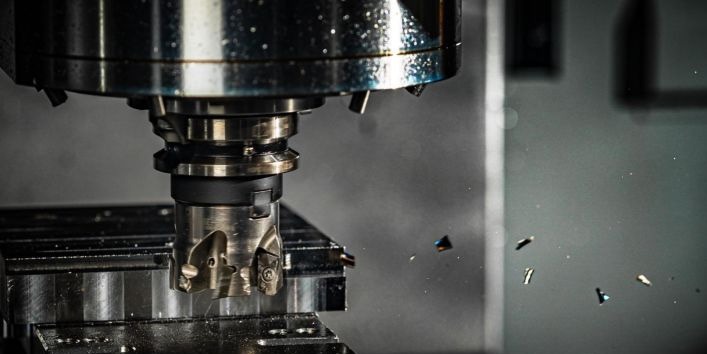

CNC machining is a widely utilized manufacturing process that enables the production of precise and intricate parts from various materials, including plastics. When it comes to CNC plastic machining, selecting the right material is crucial to ensure the desired performance, functionality, and durability of the final product. In this article, we will explore the different types of CNC plastic materials commonly used, their unique properties, and provide valuable insights on how to choose the most suitable material for your CNC machining project.

There are several types of plastic materials commonly used in CNC machining, each with its own unique properties. Here are some of the most commonly used CNC plastic materials:

- Acrylic (PMMA): Acrylic is a transparent plastic known for its excellent optical clarity. It is lightweight, easy to machine, and has good impact resistance. Acrylic is often used for signage, display cases, and decorative parts.

- Polycarbonate (PC): Polycarbonate is a strong and impact-resistant plastic. It has high transparency and can withstand high temperatures. Polycarbonate is commonly used for applications that require durability, such as protective covers, machine guards, and automotive components.

- ABS (Acrylonitrile Butadiene Styrene): ABS is a tough and durable plastic that is resistant to impact and heat. It is commonly used in consumer electronics, automotive parts, and household appliances. ABS can be easily machined and offers good dimensional stability.

- Nylon (Polyamide): Nylon is a versatile plastic known for its high strength, excellent wear resistance, and low friction properties. It is used in a wide range of applications, including gears, bearings, structural components, and industrial machinery parts.

- POM (Polyoxymethylene): POM, also known as Delrin or Acetal, is a low-friction engineering plastic. It has high stiffness, good dimensional stability, and excellent resistance to wear and chemicals. POM is often used in precision gears, bearings, and electrical components.

- PVC (Polyvinyl Chloride): PVC is a widely used plastic known for its chemical resistance and good electrical insulation properties. It can be machined easily and is commonly used in pipes, fittings, electrical enclosures, and construction materials.

- HDPE (High-Density Polyethylene): HDPE is a lightweight and strong plastic with excellent chemical resistance. It is commonly used in applications such as containers, tanks, pipes, and packaging materials.

These are just a few examples of CNC plastic materials, and there are many other types available with different properties and applications. When choosing a plastic material for CNC machining, it’s important to consider factors such as mechanical properties, chemical resistance, temperature resistance, and the specific requirements of your project.

How to Choose the Plastic Materials for CNC Machining

Choosing the right plastic material for CNC machining involves considering several factors to ensure that the selected material meets the requirements of your project. Here are some steps to help you choose the appropriate plastic material:

- Identify project requirements: Understand the specific needs of your project. Consider factors such as mechanical properties (strength, stiffness, impact resistance), chemical resistance, temperature resistance, dimensional tolerances, electrical properties, and appearance requirements.

- Evaluate material properties: Research different plastic materials and compare their properties to your project requirements. Consider factors such as strength, hardness, flexibility, wear resistance, friction properties, and thermal conductivity. Pay attention to any special characteristics or limitations of each material.

- Consult material datasheets: Obtain datasheets or technical information for the plastic materials you are considering. Datasheets provide detailed information about the material’s properties, machining guidelines, temperature limits, and other relevant data. Analyze the information to determine if the material aligns with your project needs.

- Consider cost and availability: Evaluate the cost and availability of the plastic materials. Some materials may be more expensive or harder to source than others. Take into account your budget and the feasibility of obtaining the required material within your desired timeframe.

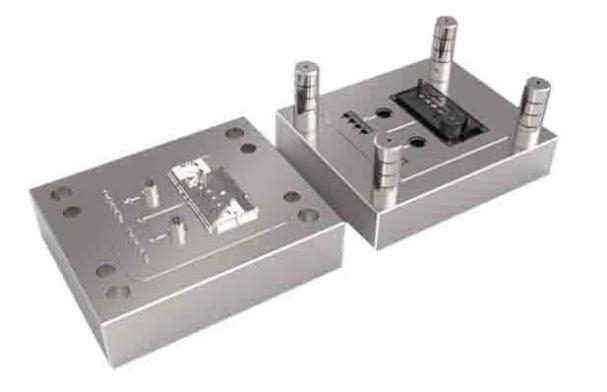

- Test prototypes: If possible, create prototypes or small test pieces using the selected materials. This allows you to assess how the material performs in terms of machining, dimensional accuracy, and desired physical properties. It also helps you identify any unforeseen issues or challenges that may arise during the machining process.

- Seek expert advice: If you’re unsure about the best material choice for your project, consult with material suppliers, CNC machining professionals, or engineers who specialize in plastics. They can provide valuable insights and recommendations based on their expertise and experience.

Remember that the choice of plastic material will depend on the specific requirements of your project. Consider the desired mechanical properties, environmental conditions, manufacturing processes, and any regulatory or industry standards that may apply. Taking the time to carefully evaluate and select the right plastic material will help ensure the success and performance of your CNC machined parts.

Conclusion

Remember that the choice of plastic material will depend on the specific requirements of your project. Consider the desired mechanical properties, environmental conditions, manufacturing processes, and any regulatory or industry standards that may apply. Taking the time to carefully evaluate and select the right plastic material will help ensure the success and performance of your CNC machined parts.

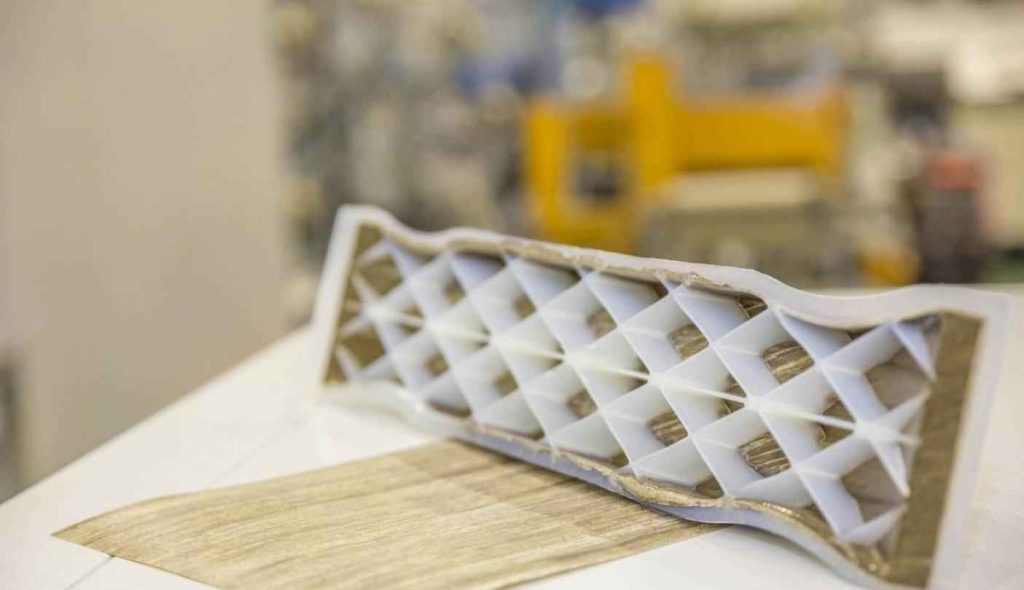

Choosing the appropriate plastic material for CNC machining is a critical decision that significantly impacts the success and quality of your project. By thoroughly understanding your project requirements, evaluating material properties, considering cost and availability, conducting prototype testing, and seeking expert advice, you can make an informed choice that aligns with your specific needs. Whether you require transparency, impact resistance, chemical compatibility, or dimensional accuracy, there is a wide range of CNC plastic materials available to meet diverse application demands. By contacting us for CNC machining, we will help you select the ideal plastic material for your CNC machining project, ensuring optimal performance and desired outcomes.