Agricultural Machinery Parts Machining: How Small Parts Can Achieve Big Agriculture

Agriculture has always been the backbone of human civilization, evolving…

Agriculture has always been the backbone of human civilization, evolving…

Polycarbonate, a versatile engineering thermoplastic, has revolutionized numerous industries due…

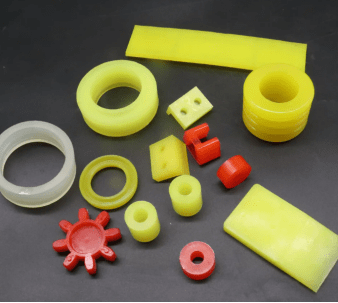

CNC machining plastics have revolutionized the manufacturing industry, enabling the creation…

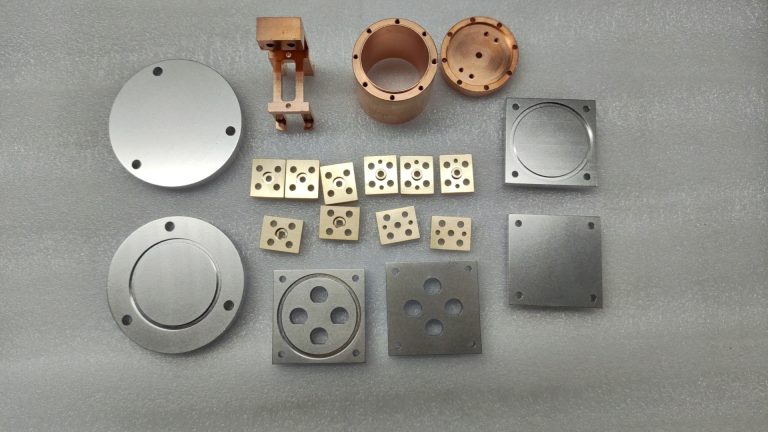

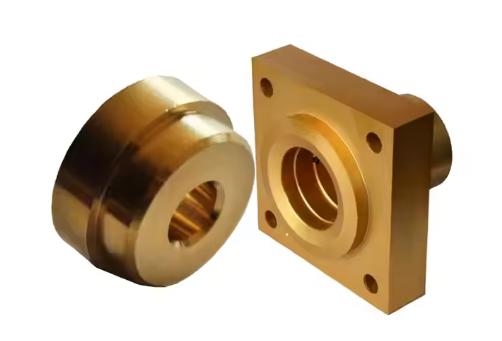

Brass, a versatile alloy composed primarily of copper and zinc,…

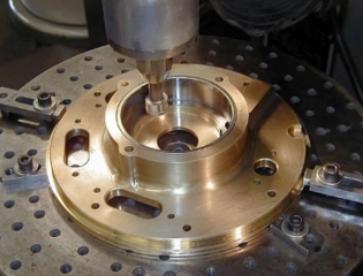

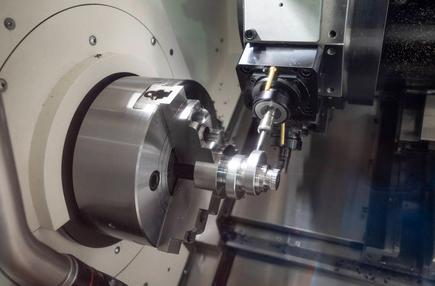

CNC (Computer Numerical Control) machining is a crucial manufacturing method…

Anodizing is a critical post-processing treatment for CNC machined aluminum parts, enhancing…

Titanium alloys are a class of metals renowned for their…

From the tiniest components to the most complex assemblies, every…

CNC machining relies on precision materials, and aluminum alloys are…

Copper and brass are two versatile metals commonly used in CNC…

ABS (Acrylonitrile Butadiene Styrene) is a versatile thermoplastic polymer widely used…

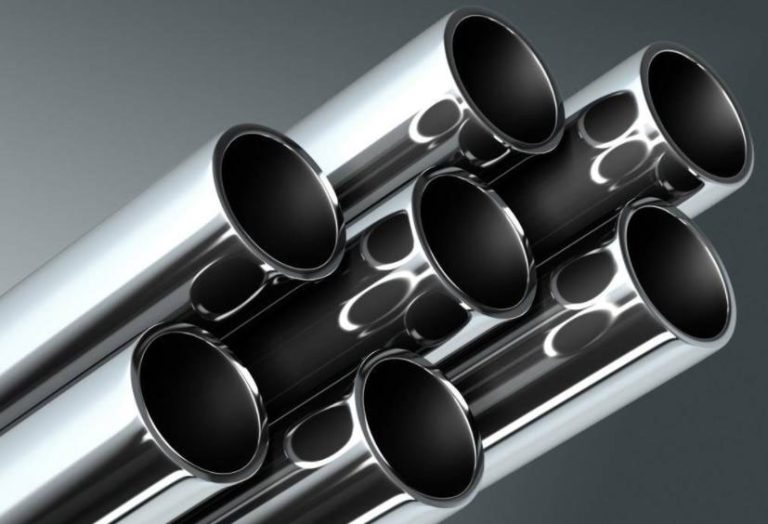

Stainless steel, renowned for its corrosion resistance, presents unique challenges…

Request A Quote