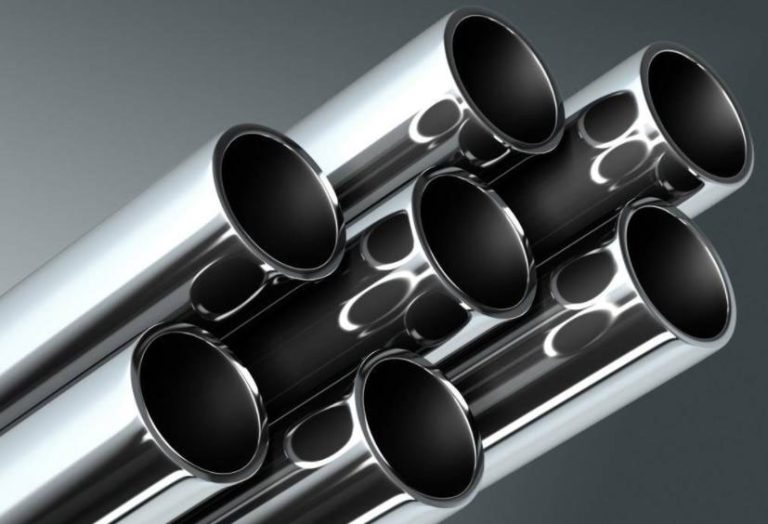

Challenges and Countermeasures in CNC Machining of Stainless Steel Parts

Stainless steel, renowned for its corrosion resistance, presents unique challenges…

Stainless steel, renowned for its corrosion resistance, presents unique challenges…

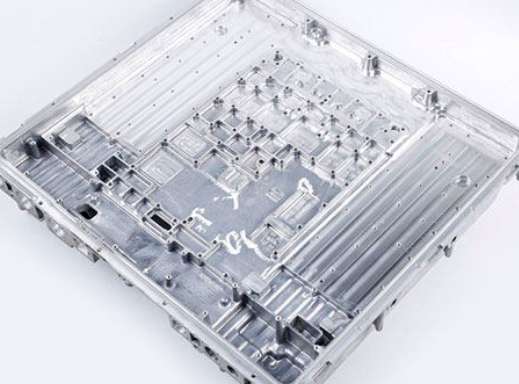

In the ever-evolving automotive industry, the demand for high-performance, lightweight…

Brass, an alloy renowned for its machinability and versatility, has…

Titanium, renowned for its exceptional strength-to-weight ratio, corrosion resistance, and…

JTR Machine, a high-quality CNC parts manufacturer in China, has…

Aluminum is a versatile material widely used in CNC milling…

Stainless steel is a popular choice for CNC machining due…

In the world of CNC machining, the ideal finish goes beyond…

Stainless steel is a popular material known for its excellent corrosion…

It is critical to thoroughly compare 3-axis, 4-axis, and 5-axis…

Brass is a versatile alloy of copper and zinc. In…

The aerospace industry is constantly pushing the limits of what…

Request A Quote