From Raw Material to High-Tech Parts: A Guide to Precision Machined Aluminum

Aluminum’s unique set of properties has made it a key…

Aluminum’s unique set of properties has made it a key…

ABS (Acrylonitrile Butadiene Styrene) plastic is a versatile material widely…

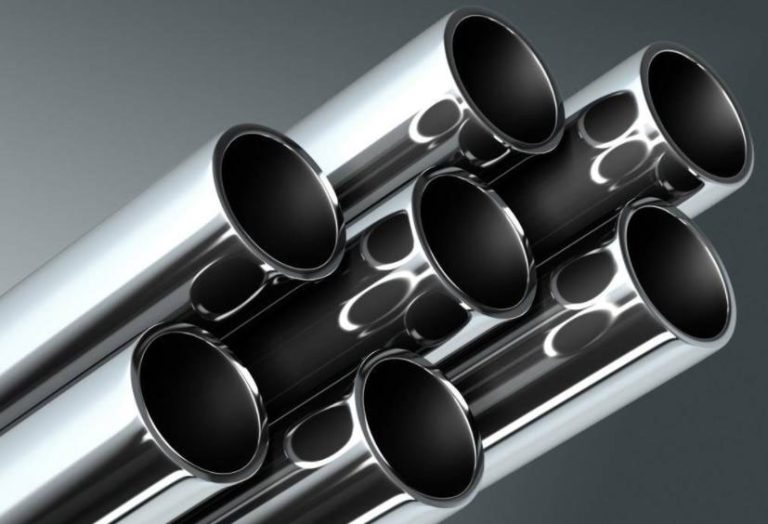

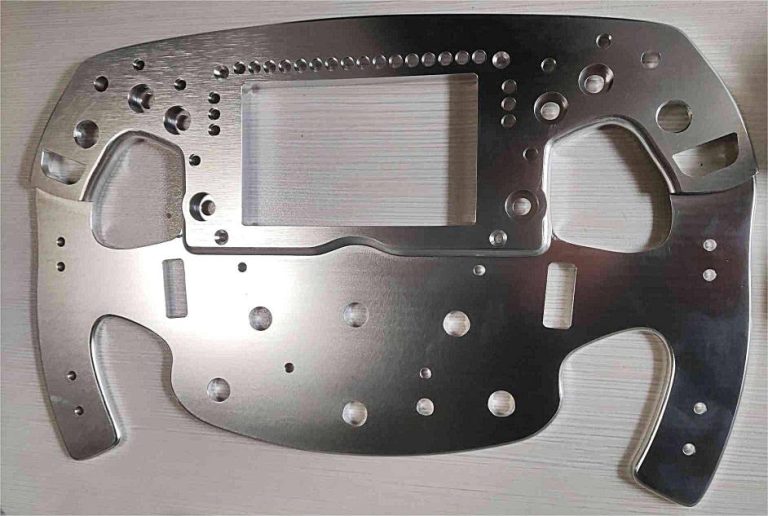

Aluminum’s distinctive combination of lightweight strength, machinability, and corrosion resistance…

CNC machining provides incredible versatility for producing precise and intricate metal…

Precision, efficiency, and material versatility are critical in today’s manufacturing…

In the ever-changing world of manufacturing, the ability to produce…

CNC machining, short for Computer Numerical Control machining, is a…

High-performance boats are the epitome of engineering excellence, combining speed,…

Carbon fiber, with its remarkable strength-to-weight ratio, has revolutionized various…

The world of CNC machining is all about precision. From…

The roar of an engine, the smooth glide of a…

CNC milling aluminum is a common practice in various industries, from…

Request A Quote