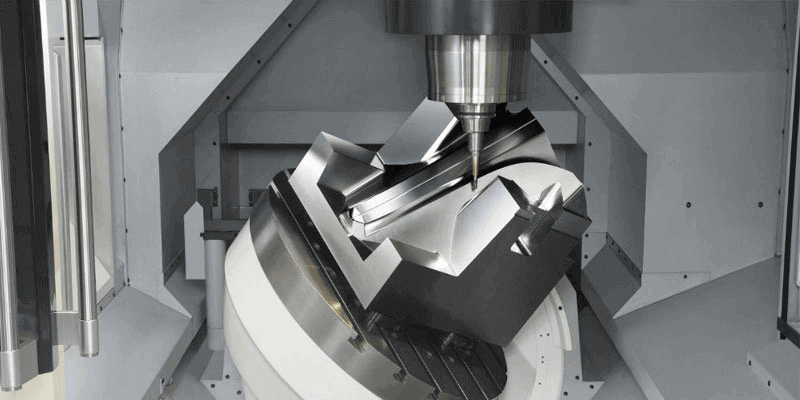

With the continuous development of CNC Machining technology, the application of CNC lathes is becoming more and more common, and CNC technology is developing in the direction of high speed and high precision. Ensuring the accuracy of parts processing is a key factor for parts production and processing enterprises to obtain economic benefits and survive in the fierce market environment. Therefore, in order to improve the accuracy of products and cope with the changing market environment, manufacturers must take relevant measures to improve the accuracy of CNC Turning. How can manufacturers ensure accuracy when CNC mass-producing parts? This article will show you JTR’s secret to being able to mass-produce super-fine parts.

Factors Affecting CNC Turning Accuracy

There are many factors that affect the accuracy of CNC turning.

First of all, there are factors that affect the accuracy of the machine tool itself. First, the geometric accuracy of the machine tool itself, the size of the power accuracy, the strength of the stiffness, etc.

Second, the installation of the fixture will also affect the accuracy of CNC turning, for example, the installation of the relative position, the size and direction of the clamping force, etc.

Third, the installation of the tool will also affect the accuracy of CNC turning, for example, the installation error, the wear of the blade, etc.

Fourth, the production workpiece will also affect the CNC turning The accuracy of turning processing, for example, the distribution of residual stress in the workpiece, the physical properties of the workpiece itself, etc.

All of the above factors may affect the accuracy of CNC turning, so it is necessary to come up with methods to reduce the influence of these factors and improve the accuracy.

How to Control the Precision of CNC Turning Batch Processing

According to the above research on the factors that affect the Turning accuracy of CNC turning, we can analyze how to improve the accuracy of CNC turning from five aspects: reasonable selection and installation of fixtures, reasonable selection and installation of tools, reasonable selection of cutting amount, determination of processing routes and improvement of programming dimensional accuracy. Analyze the accuracy of batch processing

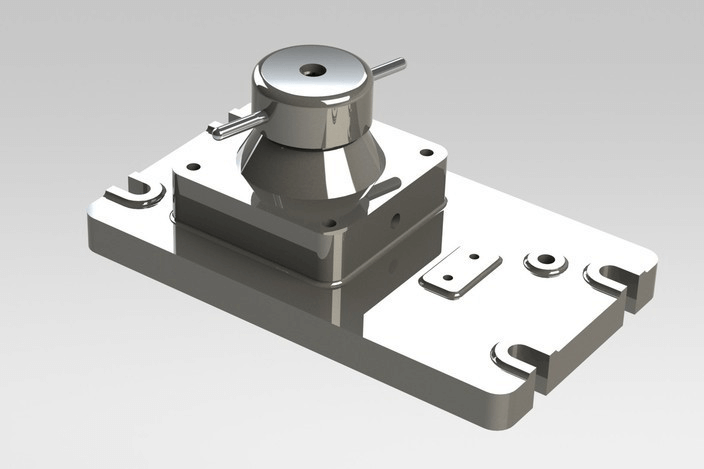

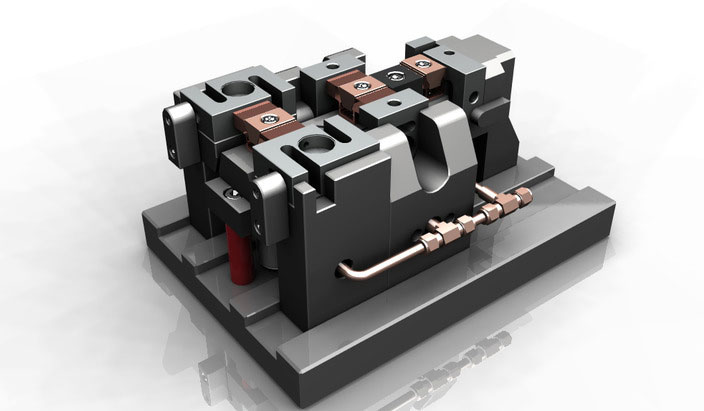

Reasonable Selection and Installation of Fixtures

When choosing a fixture, first, try to use a general-purpose fixture to clamp the workpiece, and avoid using a special fixture. Second, in order to reduce the positioning error, the part positioning benchmarks should be coincident. When installing the clamp, because the connection between the hydraulic chuck and the hydraulic clamping cylinder is realized by the pull rod, first, use a wrench to remove the nut on the hydraulic cylinder, and pull out the pull tube from the rear end of the main shaft, and then remove the chuck fixing screw, that is, remove the chuck, and install it.

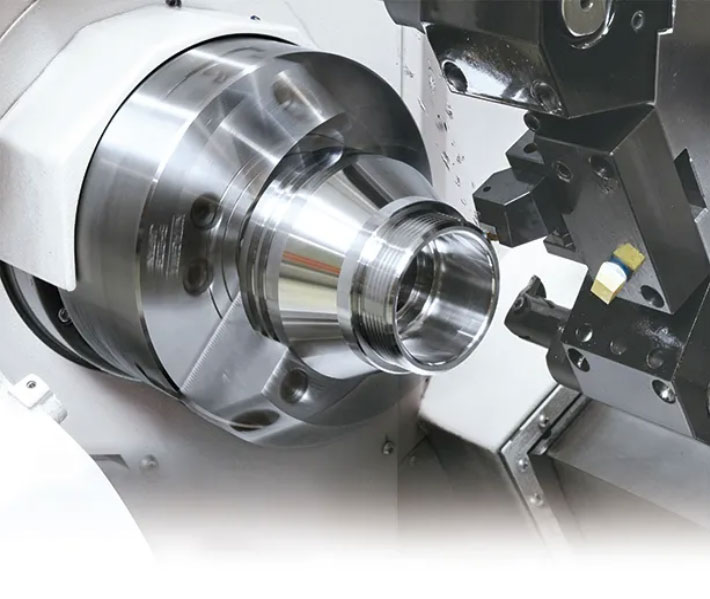

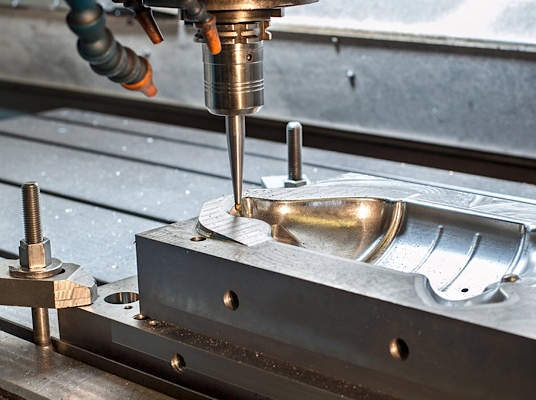

Reasonable Selection and Installation of Tools

When choosing a tool, the following three aspects should be considered. First, if it is a rough turning, it is necessary to choose a tool with high strength and high durability; second, if it is a fine turning, it must choose a tool with high precision and high durability. Thirdly, machine-clamped knives and machine-clamped blades should be used as much as possible to reduce tool change time. In the installation of the tool, the rake angle and relief angle should be appropriately increased, the main declination angle and the secondary declination angle should be reduced, and the arc radius of the tool tip should be increased, which can improve the Turning quality of the workpiece surface.

Reasonable Selection of Cutting Amount

Cutting speed, feed and depth of cut will directly cause tool damage. The increase in cutting speed will inevitably increase the temperature of the tool tip and cause thermal wear to the tool. The larger the feed rate, the faster the temperature rises during cutting, and the more severe the damage to the tool. The main purpose of controlling the depth of cut is to prevent the material being cut from producing a hardened layer and reduce the service life of the tool. Therefore, in actual operation, the user should reasonably select the cutting amount according to the actual situation.

Determine the CNC Turning Processing Route

The determination of the turning route will also affect the cutting accuracy. Generally speaking, the determination of the processing route should ensure the requirements of processing accuracy and surface roughness, and also try to shorten the processing distance and reduce the time of the tool idle travel, so as to maximize the use of resources.

Improve Programming Dimensional Accuracy

In fact, the entire process of CNC turning is completely controlled by the realization of the programmed processing program, so the accuracy and practicability of the processing program will directly affect the precision of CNC turning. Because the processing procedure can be controlled by programming the processing program, it has high flexibility and adaptability. Generally speaking, in order to ensure that the size of the production workpiece is not less than the size required by the user, you can first increase the allowance and measure it after processing to obtain the error size. At this time, you can reduce the allowance by changing the processing program. The error is minimized, so that the user’s precision requirements can be achieved.

Precautions

Although the entire process of CNC turning is completed by a pre-set program, there are still two details that require the operator to pay special attention. First, the measurement of the workpiece size must wait until the workpiece is cooled to room temperature, otherwise the cutting heat on the workpiece will affect the accuracy of the measurement; quality.

Conclusion

CNC turning processing is an automatic processing method based on CNC programs. In the actual processing process, it is required that the operation must have strong program instruction application ability and rich practical skills, so that high-quality processing programs can be compiled and the processing efficiency can be improved. Precision, processing high-quality workpieces.