CNC(Computer Numerical Control) machining is a type of subtractive manufacturing, which means that during the production process, material is removed rather than added. This means that CNC machining begins with a block of material (referred to as a blank) and swiftly removes material with moving cutters to produce the finished product.

The world of engineering has seen a dramatic transformation thanks to CNC machining. Today, practically every technical business uses it as one of the most common digital manufacturing techniques.

We’re thrilled to explain what CNC machining is and how it functions to you today as industry leaders who are passionate about all things CNC.

Types of CNC Machines:

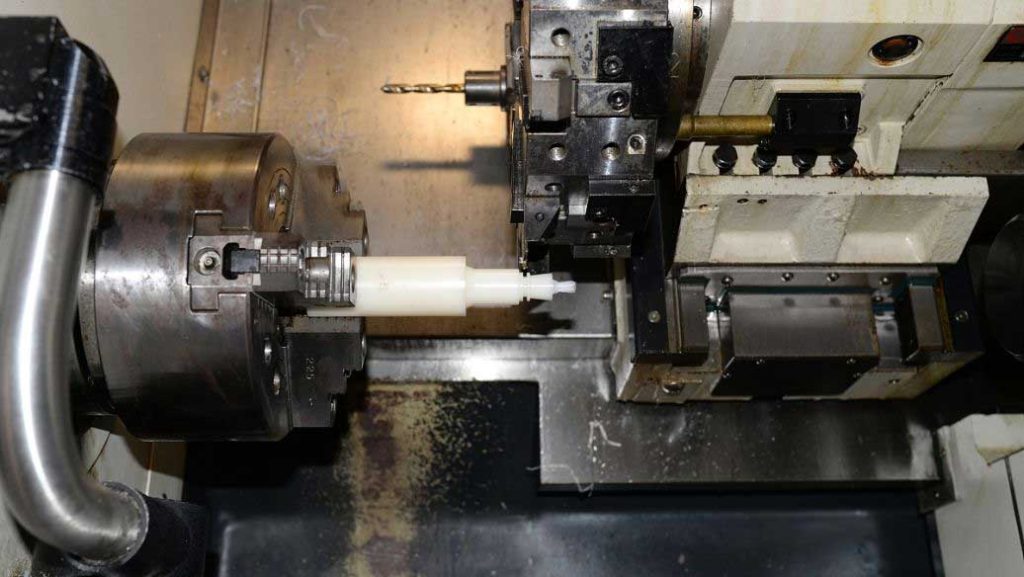

- Milling machines: To remove material, milling machines employ a rotating cutter.

- Drills: To make holes and various shapes, a drill rotates a drill bit against the material.

- Lathes: To shape material to specifications, lathes gradually spin it against a cutting tool.

- Waterjet, laser, and plasma cutters: These devices employ cutting-edge technology to cut items out of sheet metal.

CNC machines are ideal for high-volume applications because they automate several milling jobs with high levels of precision.

Applications for CNC Machines

CNC milling and machining have a wide range of applications across various industries due to their precision, flexibility, and efficiency. Some specific applications include:

- Prototyping: CNC milling and machining are widely used in product development for creating prototypes of parts and components before mass production. This allows engineers to test and refine designs quickly and cost-effectively.

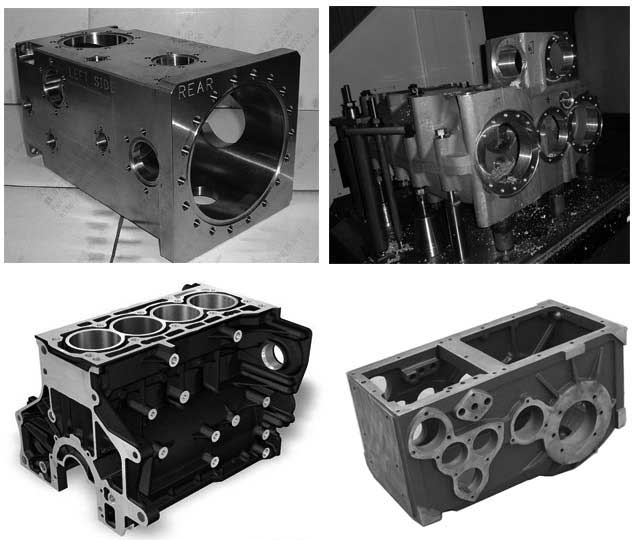

- Automotive Industry: CNC milling is used extensively in the automotive industry for manufacturing parts such as engine components, transmission parts, chassis components, and prototypes.

- Aerospace Industry: CNC machining is crucial in the aerospace industry for producing complex components with tight tolerances, such as turbine blades, engine components, structural parts, and prototypes.

- Medical Device Manufacturing: CNC milling is used to produce intricate components for medical devices, implants, prosthetics, surgical tools, and equipment with high precision and accuracy.

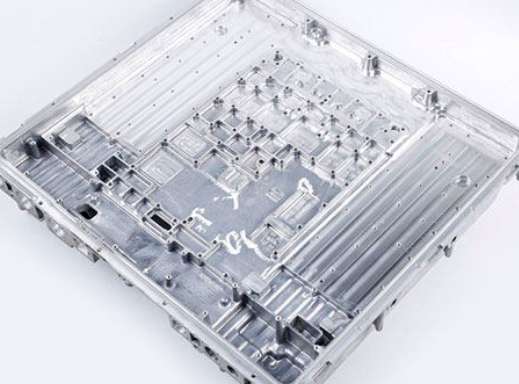

- Electronics Manufacturing: CNC machining is used to fabricate custom enclosures, heat sinks, connectors, and other components for electronic devices. It is also used in the production of printed circuit boards (PCBs) and electrical connectors.

- Tool and Die Making: CNC milling is utilized in the production of molds, dies, and tooling for various manufacturing processes such as injection molding, stamping, and casting.

- Customized Parts Production: CNC machining enables the production of customized parts and components for various industries, including consumer goods, industrial machinery, and robotics.

- Woodworking and Furniture Manufacturing: CNC milling is used in woodworking and furniture manufacturing to create intricate designs, carvings, and precise cuts in wood, plywood, MDF, and other materials.

- Jewelry Making: CNC milling machines are used in jewelry making to create intricate and detailed designs on metals such as gold, silver, and platinum.

- Military and Defense: CNC machining is employed in the production of military equipment, including firearms, ammunition, vehicle parts, and specialized components for defense systems.

Overall, CNC milling and machining find applications wherever there is a need for precision, repeatability, and efficiency in manufacturing parts and components. The technology continues to advance, enabling even more intricate and complex designs to be produced with high accuracy.

Benefits of CNC Machines

- Zero Errors and Higher Accuracy

Precision turning machines avoid the chance of human mistakes entering into the manufacturing process and resulting in faults because they operate autonomously and without any operator interference. The machines can give more accuracy with no errors when codes and software programs guide the entire operation.

- Quicker and More Effective Production

These machines can operate nonstop for a full seven days a week without getting tired or needing breaks.

- Improved Staff Safety

These machines may operate without an operator, which lowers the danger of injuries and reduces the likelihood of mishaps.

In order to avoid malfunctions, human interaction is reduced to a supervisory role where they can remotely monitor the operation of the software programs. This reduces the need for engagement and makes the workplace safer.

- Lower Production Costs as a Result of CNC Machining

With the aforementioned benefits in mind, it should be obvious that using CNC machines for the precise turning of components can significantly reduce production costs. First off, it increases manufacturing and assembly efficiency and scalability without increasing material waste.

What Consequences Come with a CNC Milling Machine?

Cost: CNC equipment typically costs more and needs a larger upfront investment than manual machines.

There Are Not Enough Trained Technicians: Even though much of the machining is automated, highly skilled technicians or experienced engineers are still needed to configure the machines, perform calculations, and oversee the machining process.

Material Waste Increased: A subtractive manufacturing technique is CNC machining. Starting with a block of material, various pieces are removed until just the finished product is left. Greater material waste results as compared to additive manufacturing techniques like 3D printing.

Conclusion

JTR can provide you with high-quality CNC machining services, including CNC turning service, CNC milling service, wire EDM service, etc. If you have drawings or want to make CNC machining parts, please contact JTR.