6061 T6 aluminum reigns supreme as the go-to material for countless applications across industries, thanks to its exceptional strength, light weight, and outstanding machinability. Its versatility and ease of fabrication have made it a darling of designers and engineers alike, but to truly unlock its full potential, partnering with an experienced aluminum machining manufacturer is key. This guide delves into the secrets of efficiently machining 6061 T6 aluminum, empowering you to achieve optimal results, minimize processing time, and maximize project success.

What is 6061 T6 Aluminum?

6061 T6 aluminum is a heat-treatable alloy composed primarily of aluminum, magnesium, and silicon. The “T6” designation indicates that the material has been solution heat-treated and artificially aged, resulting in a high tensile strength, yield strength, and hardness compared to other aluminum alloys.

| Tensile Strength, Yield (MPa) | Young’s Modulus (E) | Density (ρ) | Specific Heat Capacity (c) | Elongation (ε) at break |

| 124–290 MPa (18.0–42.1 ksi) | 68 GPa (9,900 ksi) | 2.70 g/cm3 | 897 J/(kg·K) | 12–25% |

Properties of 6061 T6 Aluminum:

- High Strength: In the T6 temper, 6061 boasts a tensile strength of around 310 MPa (45,000 psi), offering a great strength-to-weight ratio.

- Excellent Corrosion Resistance: The natural oxide layer protects the aluminum from corrosion in most environments, reducing maintenance needs.

- Good Weldability: With proper procedures, 6061 T6 can be welded to form strong joints.

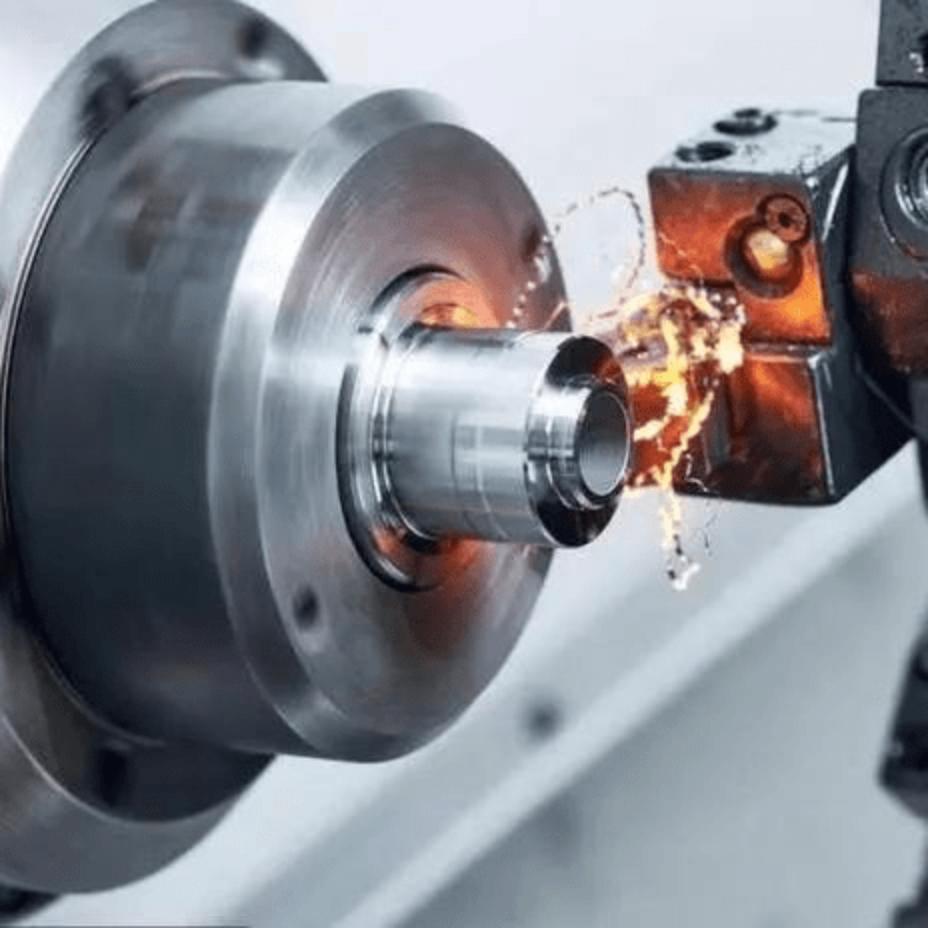

- Outstanding Machinability: Easily cuts and shapes with CNC machining, milling, turning, and other techniques, resulting in smooth finishes.

- Moderate Formability: Can be bent, formed, and rolled to adapt to various design requirements.

- Decent Electrical Conductivity: Conducts electricity moderately, making it suitable for some applications like heat sinks and electrical connectors.

- Fair Thermal Conductivity: Conducts heat reasonably well, finding applications in heat sinks and engine components.

Why 6061 T6 is Preferred for Machining?

The combination of its advantageous properties makes 6061 T6 a top choice for machinists:

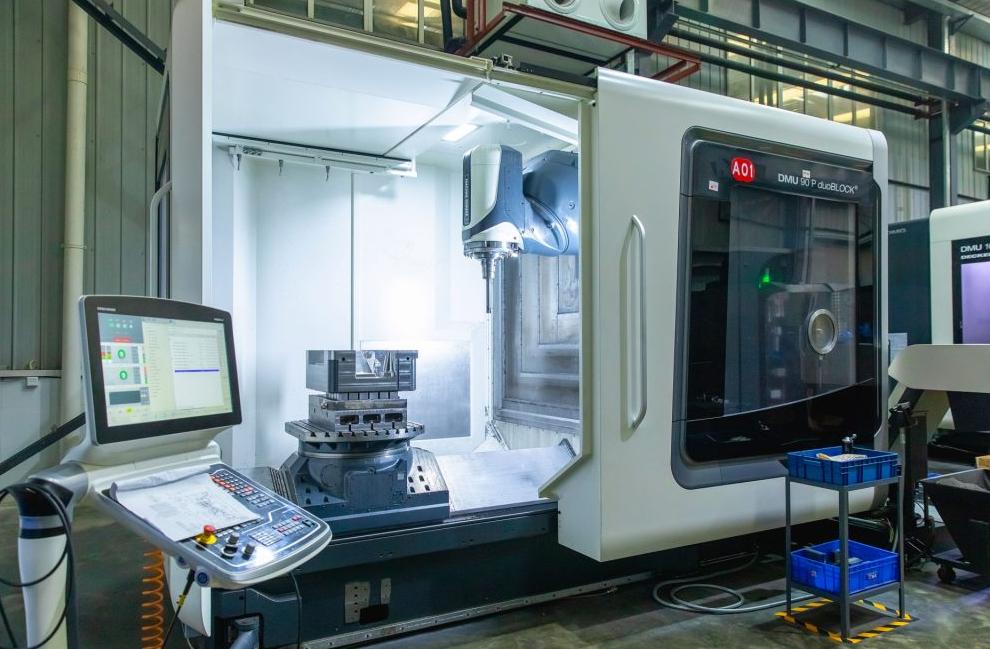

- Easy to Machine: Its excellent machinability translates to faster production times, lower machining costs, and longer tool life.

- Versatile: 6061 T6’s adaptability allows it to be machined into a wide range of shapes and sizes, catering to diverse project requirements.

- Reliable Strength: The high strength-to-weight ratio ensures machined parts can handle significant loads without sacrificing weight efficiency.

- Durable: Good corrosion resistance makes machined 6061 T6 components suitable for long-term use in various environments.

What are the Finishing Techniques for Machining 6061 T6 Aluminum?

Various finishing techniques can enhance the appearance and functionality of machined 6061 T6 aluminum:

- Anodizing: Creates a hard, protective oxide layer that improves corrosion resistance, wear resistance, and aesthetics.

- Powder Coating: Provides a durable, decorative finish with a wide range of color and texture options.

- Painting: Offers an aesthetically pleasing and protective finish in various colors and textures.

- Brushing: Creates a satin or brushed metal finish for a more industrial look.

- Polishing: Achieves a high-gloss, mirror-like finish for maximum visual appeal.

5 Considerations for Machining 6061 T6 Aluminum:

To ensure efficient and successful machining, certain factors need to be considered:

- Tool Selection: Use sharp, high-quality carbide or HSS tools specifically designed for aluminum machining.

- Cutting Speeds and Feeds: Maintain high cutting speeds (800-1500 SFM) and moderate feeds to achieve optimal chip formation and minimize tool wear.

- Coolant: Use a proper coolant to lubricate the cutting tool and workpiece, prevent heat buildup, and improve chip evacuation.

- Toolpath Optimization: Optimize toolpaths to minimize tool dwell time and reduce cycle times.

- Burr Control: Use appropriate tools and techniques to minimize burr formation and simplify finishing processes.

3 Tips for Troubleshooting Common Machining Problems with 6061 T6 Aluminum:

Machining 6061 T6 typically presents minimal challenges, but here are some troubleshooting tips for common issues:

- Chatter: Reduce cutting speeds and feeds, ensure tool rigidity, and optimize toolpaths.

- Built-up Edge: Increase feeds, use sharp tools, and apply proper coolant.

- Tool Wear: Choose the right tool material and geometry, maintain proper cutting speeds and feeds, and use coolant

Conclusion

Mastering the machining of 6061 T6 aluminum unlocks a world of possibilities for your projects. By understanding its properties, leveraging its strengths, and addressing its nuances, you can achieve efficient, high-quality results. Remember, proper tool selection, optimal cutting parameters, and effective finishing techniques are key to maximizing the potential of this versatile material. By choosing a skilled aluminum machining manufacturer with a proven track record, you gain access to cutting-edge technology, optimized tool selection, and meticulous quality control procedures. With their guidance and specialized capabilities, you can transform your vision into reality with precision, efficiency, and unwavering performance.