In the fast-paced and dynamic worlds of aerospace and automotive manufacturing, precision is the name of the game. These industries demand the utmost accuracy and reliability in every component, and this is where CNC turning parts shine. Computer Numerical Control (CNC) turning is a highly advanced machining process that has become the backbone of modern manufacturing, offering unparalleled precision, performance, and progress in the aerospace and automotive sectors.

What is CNC Turning?

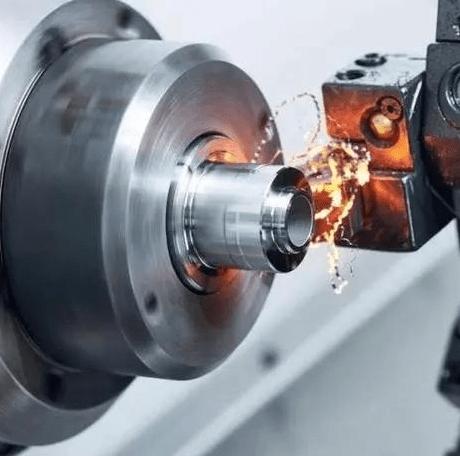

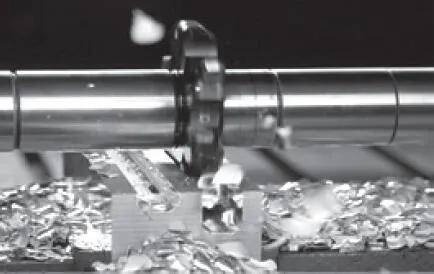

CNC turning is a manufacturing process that involves the removal of material from a workpiece to create intricate and highly accurate parts. This process is used to produce cylindrical or conical components by rotating the workpiece while a cutting tool moves along its axis. The cutting tool’s position and movement are precisely controlled by computer software, making it an incredibly precise and repeatable method of manufacturing.

CNC Turning Parts in Aerospace: Where Every Fraction of a Millimeter Matters

Aerospace is one of the most demanding sectors when it comes to precision engineering. Aircraft, spacecraft, and other aerospace vehicles require components that are not only durable but also incredibly precise. Even the smallest deviation can have catastrophic consequences. This is where CNC turning parts play a pivotal role.

- Complex Components: Aircraft and spacecraft often rely on intricate components like turbine blades, landing gear parts, and engine components. CNC turning can produce these complex parts with tight tolerances and high repeatability.

- Lightweight Materials: The aerospace industry is continuously pushing the boundaries of materials to reduce weight and enhance performance. CNC turning can handle a wide range of materials, from aluminum and titanium to advanced composites.

- Consistency and Reliability: The aerospace industry can’t afford component failure. CNC turning ensures every part meets stringent quality standards, minimizing the risk of defects and failures.

- Rapid Prototyping: In an industry where innovation is key, CNC turning allows for rapid prototyping and the testing of new designs and materials.

CNC Turning Parts in Automotive: Efficiency and Quality in Mass Production

- Engine Components: Precision is paramount in the production of engine components, such as crankshafts, camshafts, and pistons. CNC turning ensures these parts meet exact specifications, contributing to engine efficiency and longevity.

- Transmission Parts: Gear manufacturing requires the highest level of precision, and CNC turning delivers. Precise gear teeth and shafts are vital for smooth and reliable transmission operation.

- Customization: As consumer preferences evolve, customization becomes a key feature. CNC turning allows for the efficient production of custom components, catering to the diverse demands of the automotive market.

- Cost Efficiency: Mass production is a cornerstone of the automotive industry, and CNC turning helps reduce production costs by minimizing waste and ensuring consistent quality.

Challenges and Innovations of CNC Turning

While CNC turning has revolutionized the aerospace and automotive industries, it is not without its challenges. One of the significant challenges is the ever-increasing demand for even higher precision, tighter tolerances, and faster production. To meet these demands, manufacturers are constantly innovating.

- Advanced Materials: As both industries explore advanced materials like carbon-fiber composites and lightweight alloys, CNC turning machines are being adapted to handle these materials with precision.

- Multitasking Machines: Manufacturers are investing in multitasking CNC turning machines that can perform various operations in a single setup, reducing cycle times and increasing efficiency.

- Automation: Automation and robotics are being integrated into CNC turning processes to further enhance precision and speed, as well as to reduce labor costs.

- Digital Twins: Simulation and digital twin technology are used to optimize machining processes and ensure the highest level of accuracy.

Conclusion

CNC turning parts have played a pivotal role in the evolution of the aerospace and automotive industries. From the precise components in aircraft engines to the efficient production of vehicle parts, CNC turning service has become synonymous with precision and performance. As these industries continue to push the boundaries of technology and materials, CNC turning will remain an indispensable tool for achieving progress and ensuring the highest standards of quality and safety.