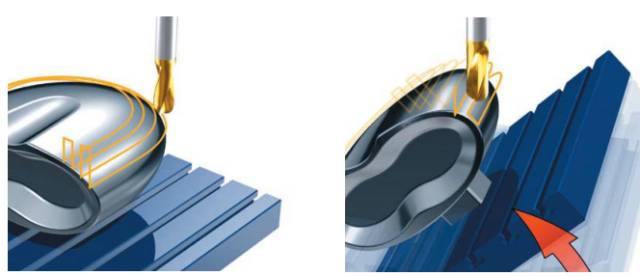

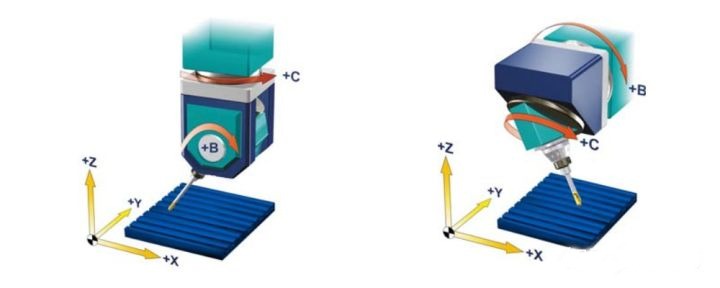

5-axis CNC machining is revolutionizing how manufacturers across various industries design, prototype, and produce intricate and high-precision components. This cutting-edge technology, unlike traditional 3-axis machining, boasts five independently controlled axes, including three linear (X, Y, Z) and two rotational (A and B). This additional dexterity allows for the simultaneous movement of the cutting tool and workpiece along multiple axes, enabling the machining of complex geometries and challenging features with unmatched precision and efficiency.

5-Axis CNC Machining Applications across Diverse Industries

The versatility of 5-axis CNC machining makes it a game-changer across various industries. Let’s delve into some of its groundbreaking applications:

1. Aerospace and Defense:

- Manufacturing lightweight, high-strength components: From intricate engine blades to structural airframe elements, 5-axis machining enables the creation of lightweight yet robust parts crucial for aircraft performance and fuel efficiency.

- Producing complex geometries: The ability to maneuver around the workpiece at various angles allows for the machining of aerodynamically optimized components and intricate internal features, enhancing aircraft performance and minimizing drag.

- Rapid prototyping and testing: 5-axis machining facilitates the rapid creation of prototypes for iterative design and testing, accelerating the development cycle of aerospace and defense technologies.

2. Medical and Dental:

- Customizing medical implants: 5-axis machining allows for the creation of personalized implants, such as joint replacements and dental prosthetics, that precisely match a patient’s unique anatomy, leading to improved surgical outcomes and patient comfort.

- Manufacturing delicate medical instruments: From surgical tools to intricate components for medical devices, 5-axis machining ensures the precise machining of delicate features and sharp edges, critical for medical instrument performance and patient safety.

- Creating biocompatible components: The ability to machine various biocompatible materials makes 5-axis CNC ideal for producing medical implants and devices that minimize the risk of rejection and ensure long-term functionality.

3. Automotive:

- Manufacturing lightweight car components: 5-axis machining enables the creation of complex, lightweight car parts, such as chassis components and engine blocks, contributing to improved fuel efficiency and vehicle performance.

- Producing intricate designs: From aerodynamic spoilers to customized interior trim pieces, 5-axis machining allows for the creation of visually appealing and functionally optimized car components.

- Rapid prototyping and design iterations: The speed and precision of 5-axis machining facilitate rapid prototyping and design iterations, accelerating the development cycle of new car models.

Beyond these industries, 5-axis CNC machining finds applications in various fields, including:

- Mold and die making: Creating complex mold and die cavities for various manufacturing processes.

- Energy and power generation: Machining high-precision components for turbines, generators, and other equipment.

- Consumer goods: Producing intricate and aesthetically pleasing components for consumer electronics, jewelry, and other products.

Advantages of 5-axis CNC machining in Manufacturing

5-axis CNC machining represents a significant leap forward in manufacturing capabilities. Its advantages extend beyond the creation of complex geometries:

- Reduced material waste: By minimizing the need for multiple setups and specialized tooling, 5-axis machining optimizes material utilization and reduces waste.

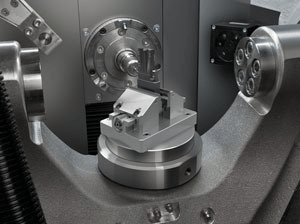

- Shorter production times: The ability to machine complex parts in a single setup significantly reduces production times, leading to increased efficiency and cost savings.

- Enhanced product quality: The precision and control of 5-axis machining ensure high-quality products with tighter tolerances and superior functionality.

As technology continues to evolve, 5-axis CNC machining will become even more sophisticated and accessible. Advancements in automation, software, and cutting tools will further unlock its potential, paving the way for even more efficient, innovative, and sustainable manufacturing processes across diverse industries.

Conclusion

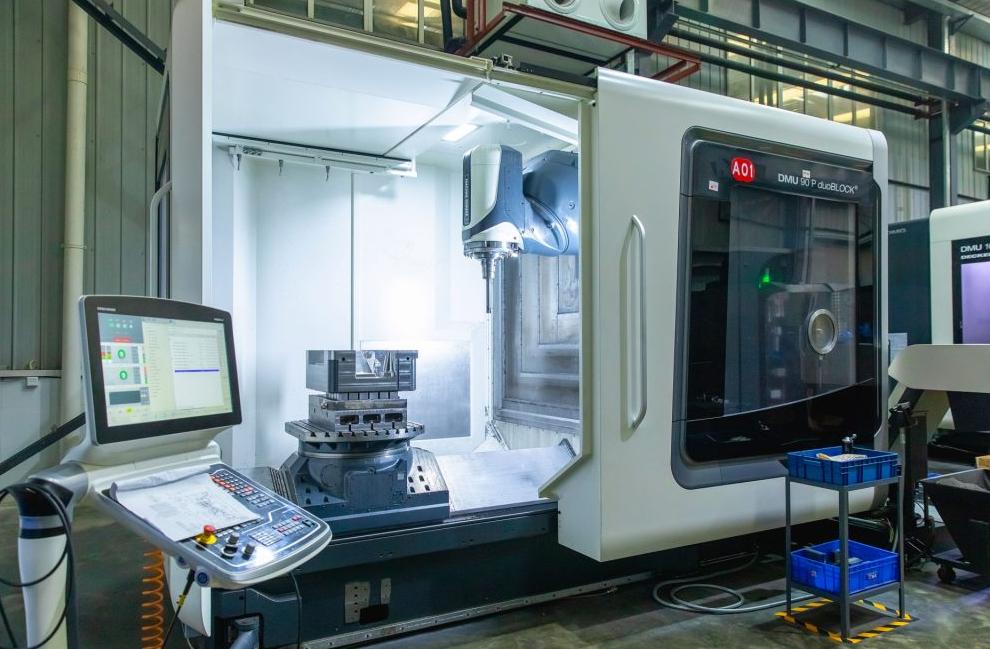

In conclusion, 5-axis CNC machining is not just a technological marvel; it is a transformative force shaping the future of manufacturing. JTR Machinery possesses 70 cutting-edge CNC Machining Centers, with various CNC machines including 3-axis, 4-axis, and 5-axis CNC machines. As we move forward, embracing 5-axis CNC machining and its cutting-edge solutions will be key to driving innovation, enhancing product quality, and ensuring long-term success in a competitive.