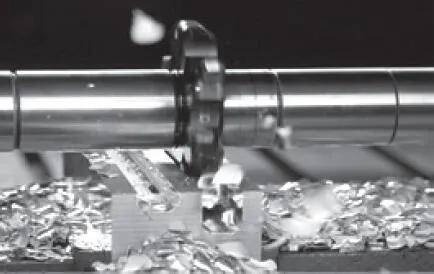

Several CNC turning operations have strict requirements on chips. To achieve an ideal turning, it is necessary to solve the problem of chip breaking. Whether the chips are easy to break is directly related to the deformation of the chips. Reasonable use of material deformation for chip breaking, technological means for chip breaking, and unique numerical control programming function of CNC machine tools for chip breaking, improve turning stability.

The Factors of Why Break Chips

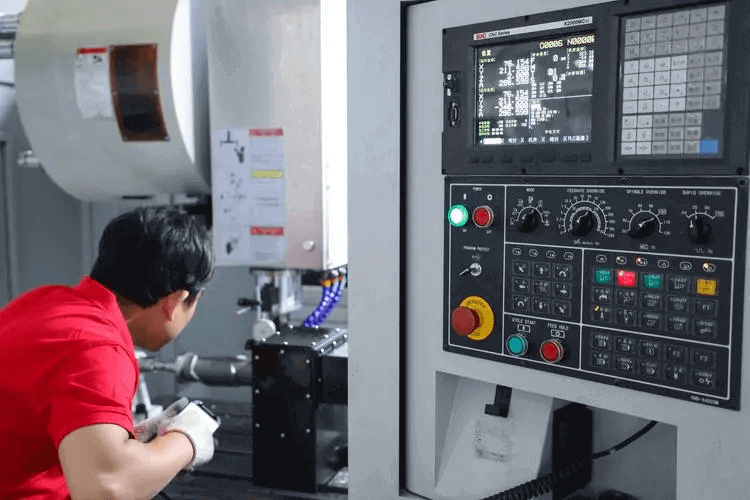

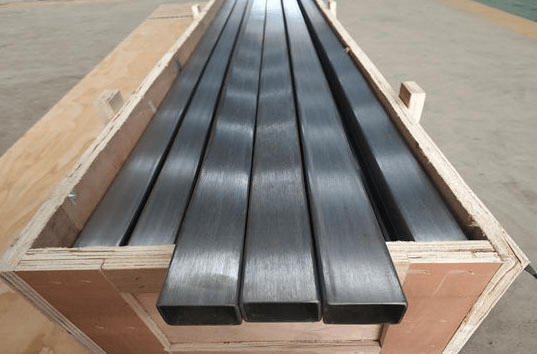

CNC lathes are modern automated manufacturing equipment that integrates mechanical manufacturing technology, microelectronics technology and computer technology, rejuvenating the traditional machinery manufacturing industry and increasing labor productivity. However, automated machine tools have strict requirements on chips. Chips entangled on the tool, the workpiece and its adjacent tools and equipment will affect the processing and cause an accident in severe cases. To achieve ideal turning, it is necessary to solve the problem of chip handling (also known as chip breaking).

The principle of chip breaking

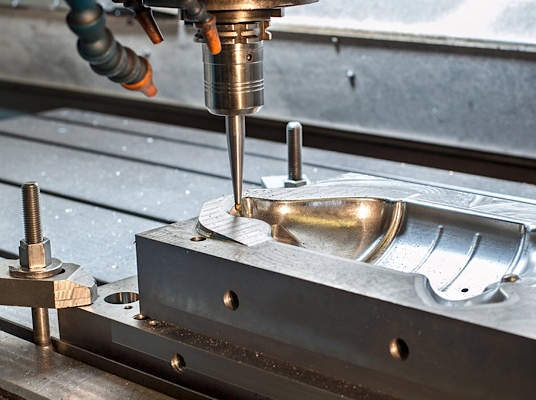

In the process of metal cutting, whether the chip is easy to break is directly related to the deformation of the chip. Due to the relatively large plastic deformation of the chips formed in the cutting process, its hardness will increase, while the plasticity and toughness will be significantly reduced. This phenomenon is called cold work hardening. After cold work hardening, the chip becomes hard and brittle, and is easily broken when subjected to alternating bending or impact loads. The greater the plastic deformation experienced by the chip, the more obvious the phenomenon of hard and brittle, and the easier it is to break. When cutting high-strength, high-plasticity, and high-toughness materials that are difficult to break, try to increase the deformation of the chip to reduce its plasticity and toughness, so as to achieve the purpose of chip breaking. Therefore, it is reasonable to use the principle of chip breakage and apply it to several car processing.

Several common chip breaking methods for turning machining

1. Chip breaking by material deformation

- Using the chipbreaker

The chip breaker not only acts as an additional deformation to the chips, but also controls the curling and breaking of the chips. As long as the shape and size of the chip breaker and the inclination angle of the chip breaker and the main cutting edge are suitable, the chip breaking is reliable. Whether it is welded or machine-clamped, regrind or indexable, it can be used. In order to apply to different cutting amount ranges, the carbide indexable inserts are pressed with various shapes and sizes of chip breakers, which are easy to select, which is economical and convenient. This method is the preferred method in machining and the most widely used method. The disadvantage is that the determination of reasonable geometric parameters of the tool is limited by the requirements of chip breaking. However, nowadays, the shapes of the chip breakers of the machine-clamped inserts are becoming more and more abundant, and the selection range is wider and wider.

- Change tool geometry parameters and adjust cutting amount

From the above-mentioned chip breaking principle, it can be seen that reducing the rake angle of the tool; increasing the main declination angle; grinding a negative chamfer on the main cutting edge; reducing the cutting speed; increasing the feed and changing the shape of the main cutting edge. Can promote chip breakage. However, these methods of chip breaking often bring some adverse consequences, such as decreased productivity, deterioration of workpiece surface quality, increased cutting force, etc. This method is rarely used on automatic lines, and sometimes only as an auxiliary means for chip breaking.

- Using a chip breaker

There are two types of chip breakers: fixed and adjustable. A chip baffle is installed on the rake face of the turning tool. When the chips flow out along the front of the tool, they are bent and broken due to the resistance of the chip baffle. The parameters Ln and α of the chip breaker can be designed and adjusted as required to ensure stable and reliable chip breaking under the given cutting conditions.

- Using a chip breaker

There are many types of chip breakers, which can be generally divided into mechanical, hydraulic and electrical. The cost of the chip breaking device is high, but the chip breaking is stable and reliable, and is generally only used on automatic lines. Chip breaker with cutter on turning tool. During turning, the chips flow out through the chip guide channel and are forcibly cut by the constantly rotating disc cutter, and the cut chips are discharged from the chip channel.

2. Chip breaking by technological means

Chip breaking by pre-grooving on the surface of the workpiece: According to the diameter of the workpiece, one or several grooves are pre-cut along the axial direction of the workpiece on the machined surface. cross-section, thus breaking. In this way, reliable chip breaking is ensured without affecting the roughness of the machined surface of the workpiece. Chip breaking is good even when machining tough materials. But grooving will be limited by the shape of the workpiece contour.

Conclusion

One of the key points to play in the efficient processing of CNC lathe automation equipment is to solve the problem of chip breakage. There are many solutions, but the chip breaker should be reasonably selected from the actual situation, the use of technological means, and the use of programming skills to cut chips. Enrich your experience on the job to promote the efficient use of CNC equipment.