As product designs become increasingly intricate—featuring undercuts, organic curves, internal channels, and thin walls—many engineers and procurement managers ask:Can mold making truly handle such complex geometries?

The answer is yes, but success depends on leveraging advanced technologies, smart design practices, and the right manufacturing expertise.

What Qualifies as “Complex Geometry” in Mold Making?

A mold is considered complex when it includes:

| Feature | Why It’s Challenging |

| Undercuts & Deep Cavities | Require sliders, lifters, or EDM to release the part |

| Freeform Curves & Thin Walls | Risk warping or uneven material flow |

| Micro-Details & Tight Tolerances | Demand ultra-precise machining & polishing |

| Internal Channels & Cooling | Require complex core/cavity or conformal cooling |

| Multi-material Integration | Needs overmolding or insert molding |

These features push the limits of traditional mold-making and demand precision tools, processes, and planning.

Can Mold Making Handle Complex Geometries?

Technically Speaking: Can Mold Making Handle Complex Geometries?

✅ Yes — with the right tools and techniques.

Modern mold making integrates multiple technologies to overcome geometric complexity:

| Technology | Application |

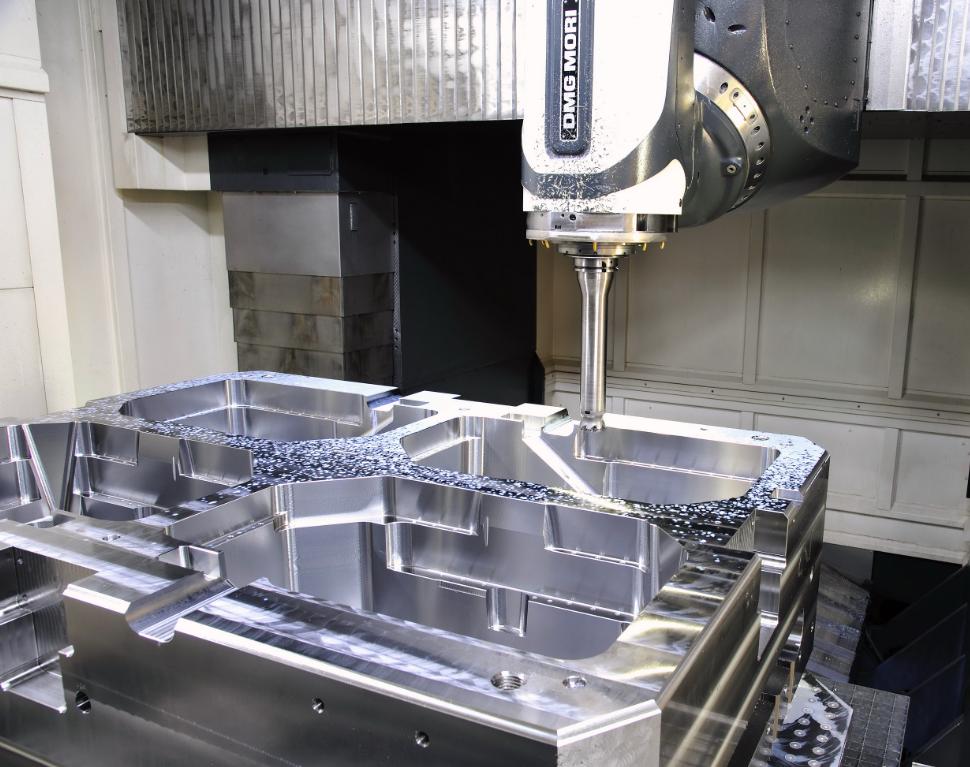

| 5-Axis CNC Machining | Allows multi-angle milling of curves, slots, and steep walls |

| EDM (Electrical Discharge Machining) | Enables precision shaping of sharp corners, deep holes |

| Conformal Cooling Design | Enhances thermal management in thin and curved sections |

| Overmolding & Dual-Shot Molding | Combines materials or colors in a single mold cycle |

| 3D Printing (Rapid Tooling) | Prototyping & low-volume validation of complex mold designs |

These tools together ensure complex geometries can be produced accurately and consistently.

Can Mold Making Maintain Accuracy in Complex Geometries

✅ Yes—but maintaining precision in complex mold designs requires deliberate engineering choices and manufacturing strategies. Common issues like warping, uneven surfaces, or tolerance drift can occur when geometry becomes intricate. Below is a quick-reference table that outlines frequent challenges and the most effective solutions used by mold-making professionals:

| Common Issue | Recommended Solutions |

| Warping or Shrinkage | Use optimized cooling systems and material simulation |

| Inconsistent Wall Thickness | Design for Manufacturability (DFM) review |

| Flash or Burrs on Undercuts | Employ tight machining tolerances and secondary finishing |

| Poor Surface Replication | Use high-speed steel, micro-tools, or mirror EDM |

With precision tolerances as tight as ±0.01mm, experienced mold makers can meet demanding product requirements even with intricate geometries.

Can Complex Geometries Increase Mold Manufacturing Costs?

✅ Yes — But Not Always Drastically. Cost is Manageable with Smart Choices.

| Complexity Level | Relative Cost Increase | Cost Reduction Tactics |

| Low (simple cores) | Baseline | Use standard inserts, avoid custom slides |

| Medium | +30–50% | Modularize complex features, use hybrid mold sets |

| High (multi-cavity complex molds) | +80–150%+ | Use rapid tooling for validation, optimize gating design |

Key Takeaway: The more complex the mold, the more expensive and time-consuming it is. However, early-stage design simplification and smart tooling strategy can significantly reduce costs.

Which Manufacturing Methods Are Best for Handling Complex Geometries in Mold Making?

| Process | Suitability for Complex Geometry | Notes |

| 3-Axis CNC | ❌ Limited | Not ideal for complex angles or deep cavities |

| 5-Axis CNC | ✅ Excellent | Ideal for freeform surfaces and deep features |

| EDM (Sink & Wire) | ✅ Excellent | Crucial for sharp internal corners and deep thin slots |

| 3D Printed Mold Inserts | ⚠️ Good for prototyping | Limited durability, best for low-volume runs |

| Hybrid Methods | ✅ Highly effective | Combine CNC + EDM + inserts for best results |

Does Complexity Affect Mold Longevity & Maintenance?

✅ Yes. Intricate molds are more prone to wear due to:

- Increased surface area contact

- Narrow vents and ejector systems

- Uneven thermal loads

How to Maximize Mold Life:

- Use tool steels like H13 or S136 for high-wear zones

- Design for replaceable inserts in complex regions

- Integrate real-time monitoring sensors for temperature and pressure

- Set up predictive maintenance plans based on cycle counts

Common Misconceptions About Complex Geometry Molding

| Misconception | Reality |

| “3D printing can fully replace steel molds” | Only viable for low-volume and low-precision applications |

| “More complex = automatically better” | Design complexity should be justified by function |

| “Precision = cost explosion” | With proper tooling, complex geometry can still be economical |

Conclusion

✅ Yes, Mold Making Can Handle Complex Geometries — If Done Right

Modern mold making can absolutely reproduce highly complex geometries, but it demands the right combination of:

- Advanced technology (5-axis, EDM, mold flow simulation)

- Smart design choices (DFM, modular features)

- Experienced tooling partners (with proven precision results)

- Cost-management strategies (hybrid tooling, validation steps)

Why Choose Chongqing Jin Te Rui Machine Co., Ltd. for Complex Mold Making?

- Advanced Manufacturing Capabilities – Specializing in high-precision CNC machining, die casting, injection molding, and rapid prototyping.

- Expertise in Complex Geometries – Experienced in handling undercuts, fine details, thin walls, and multi-material designs.

- Fast Turnaround & High Efficiency – Utilizing 3D printing, EDM, and 5-axis CNC for reduced lead times.

- Tailored Mold Solutions – Offering custom mold design, prototyping, and mass production for diverse industries.

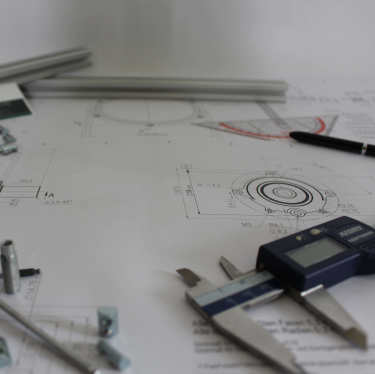

Product design and development in both 2D and 3D formats

JTR Machine’s product design services are mainly aimed at optimization. While we can also deal with all technical aspects of creating prototypes and parts. After 10 years of engagement in the industry, we’ve added new technologies in the whole process of product design and production, meeting the requirements of our customers and reducing the cost.

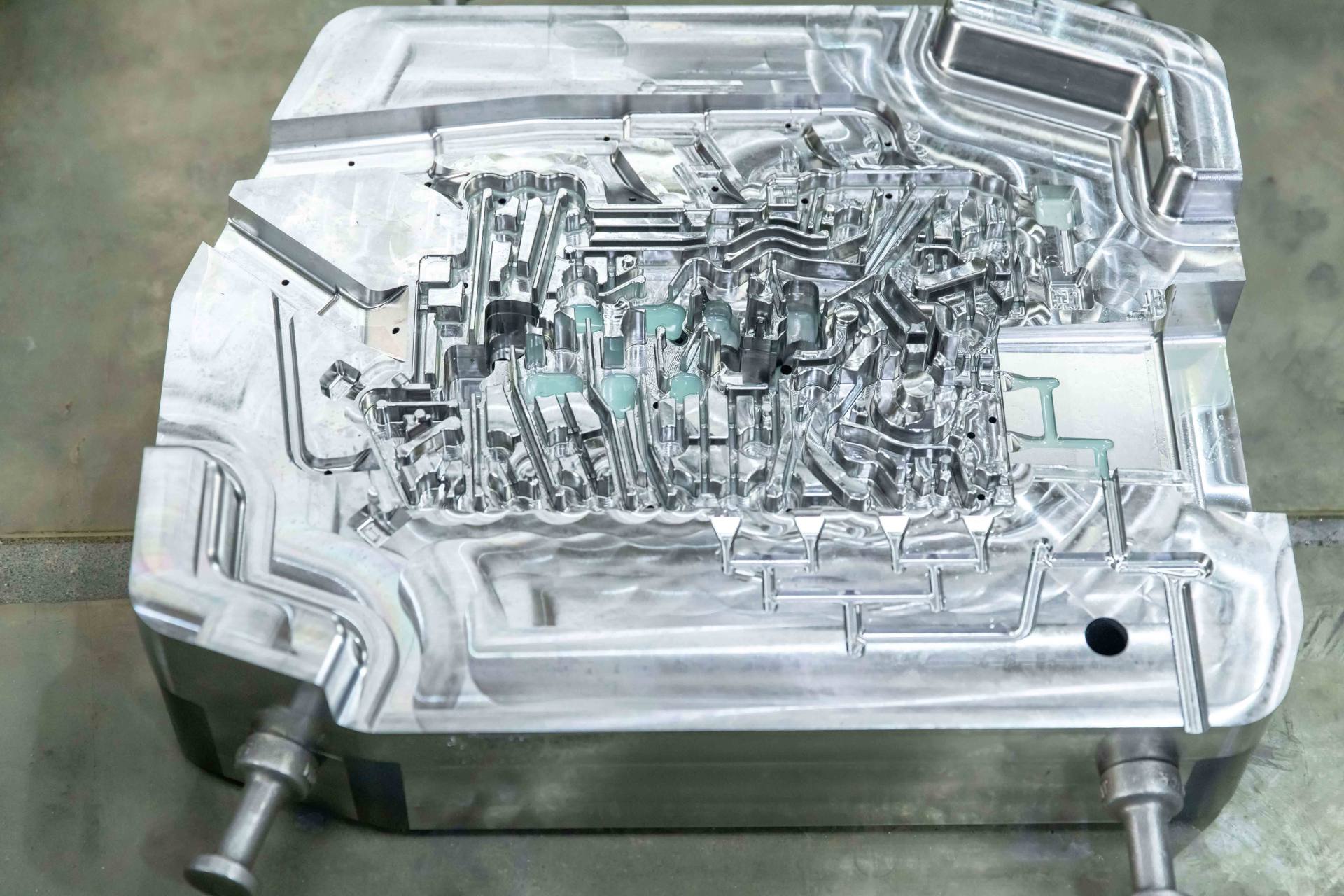

Mold making/Prototyping/Tooling

As a high-quality mold manufacturer in western China, JTR Machine’s mold-making partners can quickly make die-casting molds, injection molds, gravity casting molds, etc. Whether you need a prototype mold for short-term production or a mold for millions of batches, we can provide them with high quality and in a short lead time.