The Specific Application of Green Manufacturing in Mold

As an important pillar of rapid economic development, manufacturing also…

As an important pillar of rapid economic development, manufacturing also…

Engineering software and online resources are often expensive as software…

3D printing is additive manufacturing, a type of rapid prototyping…

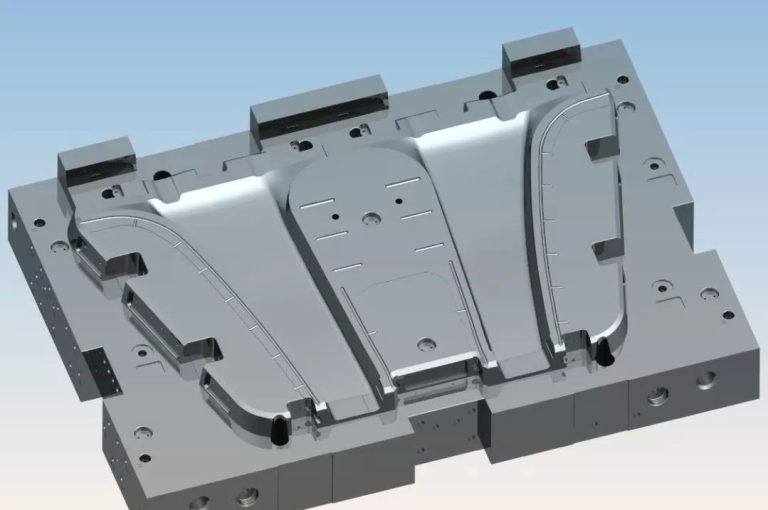

For workpieces with complex structures, traditional cutting methods are often…

In recent years, the business in the mold making manufacturing industry…

This article will introduce the commonly used mold surface finishing…

The important factor affecting the service life of the sheet…

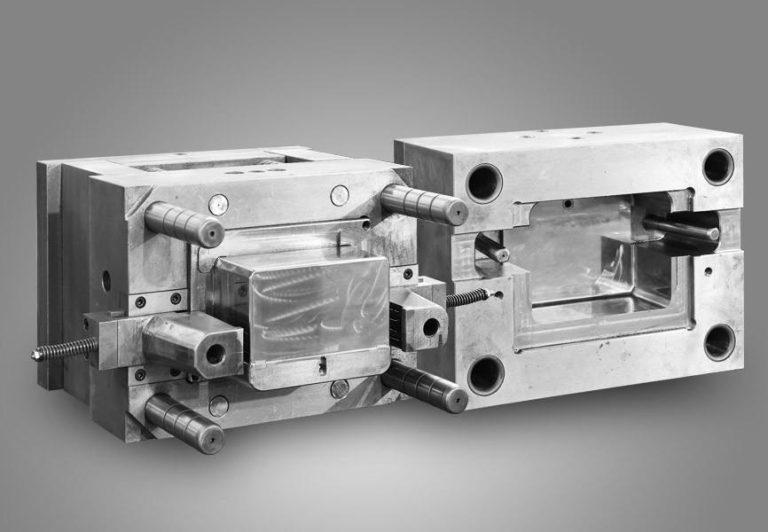

The function of the plastic mold is twofold, giving the…

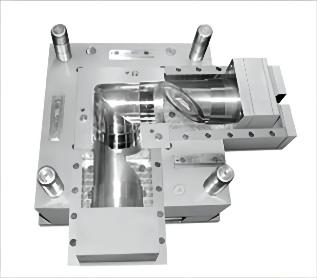

Molds are produced by injection molding, blow molding, extrusion, die…

Use rapid prototyping to make master molds and pour soft materials…

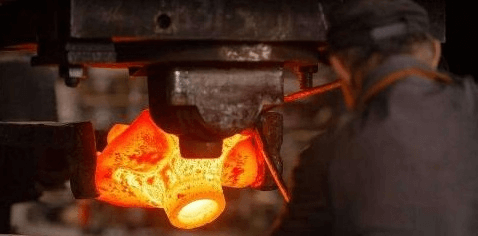

We often hear the words casting and forging in mold…

Mold manufacturing technology has developed rapidly, which has become an…

Request A Quote