The selection of metal casting mold material is not merely a manufacturing detail; it is a fundamental decision that directly influences the final quality and performance of a cast component. From microscopic grain structures to macroscopic surface finishes, the interaction between the molten metal and the mold material dictates a myriad of outcomes. This article will delve into how different mold materials exert their influence on part quality, providing a comprehensive guide for anyone involved in precision manufacturing.

Common Casting Mold Materials and Their Impact on Part Quality

Each type of casting mold material possesses a distinct set of physical and chemical properties, including refractoriness, thermal conductivity, permeability, and surface characteristics. These properties directly interact with the molten metal during pouring and solidification, leading to varying effects on the final part’s quality.

Sand Molds

Sand molds are the most traditional and widely used type of expendable molds due to their versatility and cost-effectiveness. They are made from a mixture of refractory sand grains, a binder, and sometimes additives. Once a casting is made, the mold is broken apart to extract the part.

Typical Types of Sand Molds:

- Green Sand Molds: The most common type, made from silica sand, clay (bentonite) as a binder, and water. “Green” refers to the fact that the mold is still moist when the metal is poured. They are highly permeable, allowing gases to escape.

- Dry Sand Molds: Similar to green sand, but the mold is baked in an oven before pouring to remove all moisture. This increases mold strength and reduces issues related to moisture.

- Resin-Bonded Sand Molds (Chemically Bonded): Utilize synthetic resin binders (e.g., furan, phenolic, urethane) that chemically set at room temperature or with a catalyst. These offer higher strength, better dimensional accuracy, and smoother surfaces than green or dry sand, and are often used for larger, more complex castings or cores.

Impact on Part Quality:

The inherent granular nature, relatively low thermal conductivity, and specific properties of their binders significantly influence the resulting part quality.

| Quality Parameter | Green Sand | Dry Sand | Resin-Bonded Sand |

| Surface Finish (Ra) | Rough (25 to 50μm); pronounced sand texture. | Moderately rough (12.5 to 25μm); slightly smoother than green. | Good (6.3 to 12.5μm); finer texture, less post-processing. |

| Dimensional Acc. (ISO CT) | Moderate (CT11-CT13); susceptible to mold distortion from moisture/pressure. | Good (CT10-CT12); improved stability due to baking. | High (CT9-CT11); excellent stability, less distortion. |

| Internal Defects | Prone to gas porosity (from moisture/steam), shrinkage, sand inclusions. | Reduced gas porosity (no moisture); still prone to shrinkage, sand inclusions. | Low gas porosity (good gas escape); reduced shrinkage due to better feeding, less inclusions. |

| Mechanical Properties | Coarser grain structure; generally lower strength due to slower cooling. | Slightly finer grains than green; improved strength/density. | Finer grain structure; improved strength and density. |

| Complexity & Size | Excellent for complex shapes and large sizes. | Excellent for larger, complex cores and molds. | Excellent for intricate details, deep pockets, and complex cores. |

| Cost | Very low tooling and material cost. | Low to moderate tooling/processing cost. | Moderate tooling/material cost; higher binder cost. |

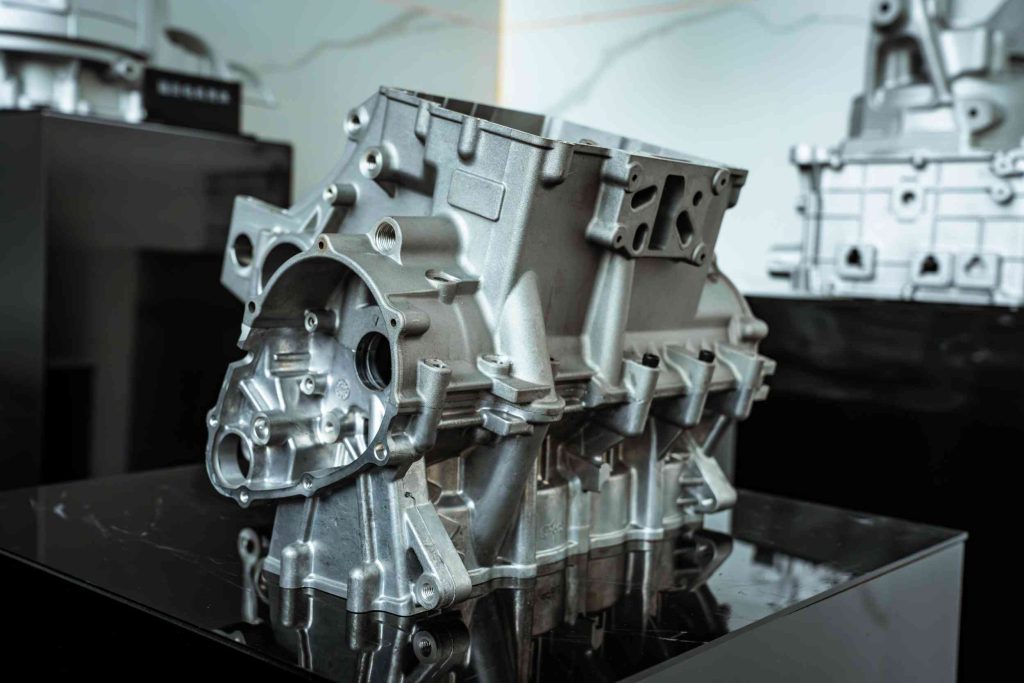

Permanent Molds (Metal Molds)

Permanent mold casting, often referred to as gravity die casting, utilizes reusable molds typically crafted from durable metals. Molten metal is usually poured into the mold cavity under gravity, or with low-pressure assistance.

Typical Types of Permanent Molds:

- Cast Iron Molds: Most common for aluminum, magnesium, and some copper alloys. Offer good thermal conductivity and resistance to thermal fatigue.

- Steel Molds: Used for higher melting point non-ferrous alloys or where greater mold strength/wear resistance is needed. Can be more expensive to machine.

- Graphite Molds (Permanent): While graphite is a material, it can be used for “permanent” molds in gravity casting, especially for copper alloys or specific ferrous applications, due to its excellent thermal shock resistance and non-wetting properties with many molten metals. (Note: These differ from disposable graphite molds in some specialty casting methods).

Impact on Part Quality (Permanent Molds):

The high thermal conductivity, rigidity, and reusability of metal permanent molds profoundly influence the solidification process and final part characteristics.

| Quality Parameter | Cast Iron Molds | Steel Molds | Graphite Permanent Molds |

| Surface Finish (Ra) | Good (3.2 to 12.5μm); smooth, minimal post-processing. | Very Good (3.2 to 6.3μm); slightly finer, higher polish. | Good (3.2 to 12.5μm); depends on graphite grade and machining. |

| Dimensional Acc. (ISO CT) | High (CT7-CT9); excellent repeatability. | Very High (CT6-CT8); slightly tighter due to higher precision machining. | High (CT7-CT9); good stability due to low thermal expansion. |

| Internal Defects | Low gas porosity (with proper venting); some micro-porosity possible; hot tear risk. | Low gas porosity; minimal micro-porosity; hot tear risk, higher stresses. | Low gas porosity (inherent permeability); less hot tear risk (better thermal shock resist). |

| Mechanical Properties | Superior strength, hardness, density (finer grain from rapid cooling). | Higher strength, hardness, density (very fine grain structure). | Good strength and density; excellent for heat transfer control. |

| Alloys Typically Cast | Aluminum, Magnesium, Brass, Bronze. | Higher temp Aluminum, some Bronze/Brass, select Ferrous (with limitations). | Copper alloys (brass, bronze), some cast iron, specialty alloys. |

| Cost | High tooling cost (moderate for permanent molds). | Higher tooling cost (more expensive to machine/maintain). | High material cost (for graphite block); good machinability. |

Ceramic Molds (Investment Casting/Lost Wax)

Ceramic molds are integral to investment casting, a process where a disposable wax pattern is coated with layers of refractory ceramic slurry to form a rigid shell. After the wax is melted out, the ceramic shell forms a precise mold cavity. The mold is destroyed to retrieve the casting.

Typical Types of Ceramic Molds (based on binder/aggregate):

- Silica-based Molds: Most common, using fused silica or colloidal silica as the binder/aggregate. Offers good cost-effectiveness for a wide range of alloys.

- Zircon-based Molds: Used for higher temperature alloys like stainless steel casting molds due to their excellent refractoriness and non-wetting properties. Provide superior surface finish and less reactivity.

- Alumina-based Molds: Employed for even higher melting point or very reactive alloys, offering extreme refractoriness and chemical stability.

Impact on Part Quality:

The use of fine ceramic materials, a disposable pattern, and controlled shell firing allows for exceptional detail and surface quality, especially for complex geometries.

| Quality Parameter | Silica-based Molds | Zircon-based Molds | Alumina-based Molds |

| Surface Finish (Ra) | Excellent (3.2 to 6.3μm); very fine details replicated. | Superior (1.6 to 3.2μm); extremely smooth, often mirror-like. | Exceptional (0.8 to 1.6μm); highest possible surface fidelity. |

| Dimensional Acc. (ISO CT) | High (CT6-CT8); precise, repeatable dimensions for intricate parts. | Very High (CT5-CT7); often tighter tolerances due to lower thermal expansion. | Extremely High (CT4-CT6); minimal distortion, ultimate precision. |

| Internal Defects | Low gas porosity; shrinkage porosity risk (slow cooling); hot tear risk. | Lower porosity; reduced reactivity with high-temp alloys; hot tear risk. | Minimal porosity and reactivity; lowest risk of inclusions; hot tear still a factor. |

| Mechanical Properties | Good to excellent due to fine grain structure from controlled cooling. | Excellent, especially for high-temp alloys (less reactivity, better microstructure). | Premium mechanical properties for demanding alloys. |

| Alloys Typically Cast | Aluminum, Brass, Bronze, Carbon Steel, Low-alloy Steel. | Stainless Steel, Nickel-based alloys, Cobalt-based alloys, some Reactive metals. | Reactive alloys (Titanium, Superalloys for aerospace). |

| Cost | High (due to expendable mold, labor-intensive); lower for common ceramics. | Very High (more expensive materials and processing). | Extremely High (specialized materials and facilities required). |

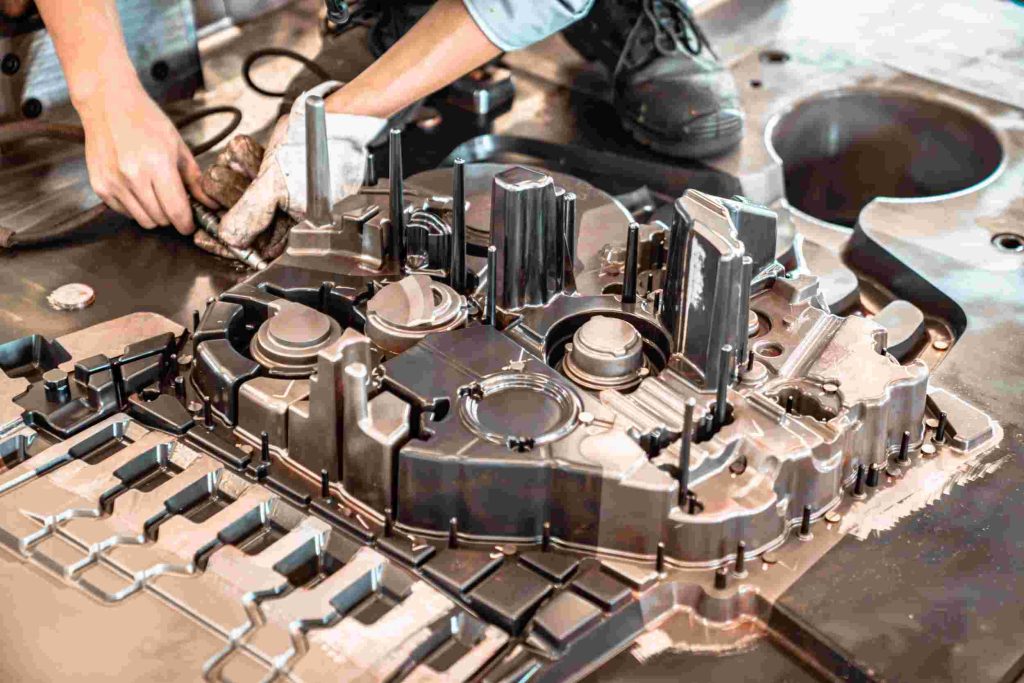

Graphite Molds (Expedient/Disposable)

While graphite can be used as a permanent mold material, it’s also utilized for “expedient” or disposable molds in certain casting processes, often machined from solid blocks of graphite. These differ from the permanent graphite molds in their typical application and lifespan.

Typical Types of Graphite Molds (based on grade):

- Fine-Grain Isotropic Graphite: High strength, good machinability, and uniform properties, used for high-precision molds.

- Medium-Grain Graphite: More economical, suitable for less critical applications or larger molds.

- Extruded/Molded Graphite: Used for specific shapes or continuous casting applications.

Impact on Part Quality:

The unique thermal and physical properties of graphite influence the casting quality, especially its thermal shock resistance and non-wetting characteristics with many molten metals.

| Quality Parameter | Typical Impact |

| Surface Finish (Ra) | Good (3.2 to 12.5μm); smoother than sand, but less so than investment/die casting. Quality highly dependent on graphite grade and machining. |

| Dimensional Acc. (ISO CT) | Good (CT8-CT10); stable dimensions due to low thermal expansion and mold rigidity. Can achieve good repeatability for short runs. |

| Internal Defects | Generally low gas porosity (inherent permeability). Effective in mitigating shrinkage (controlled cooling). Potential for surface carburization with high-carbon alloys (requires coating/control). Low risk of mold erosion. |

| Mechanical Properties | Good due to controlled cooling and finer grain structure than sand. Thermal properties allow for specific microstructures in some alloys. |

| Complexity & Size | Moderate to high complexity (can be precisely machined); adaptable for a range of sizes; often used for short production runs or prototypes due to machining costs. |

| Alloys Typically Cast | Copper alloys (Brass casting molds, Bronze casting mold), some Cast Iron, Specialty alloys (e.g., precious metals, some refractory metals), continuous casting. |

| Cost | High material cost (for graphite block); moderate machining cost; often economical for small batches or prototypes where complex geometries are needed without permanent tooling investment. |

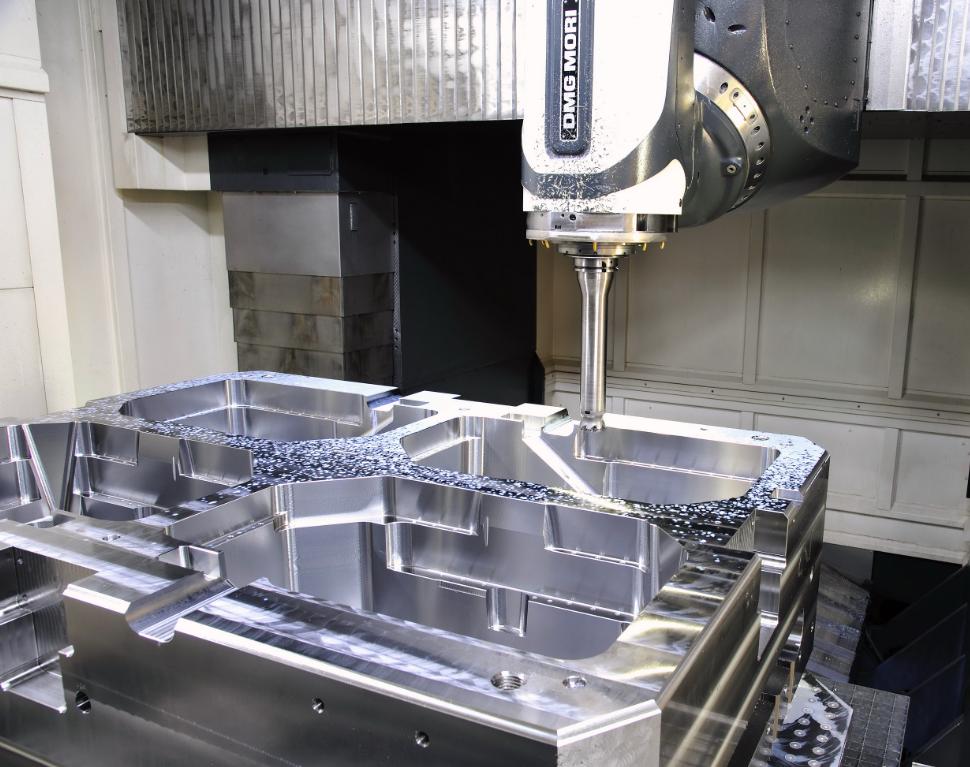

Die Casting Molds (High-Pressure Metal Molds)

Die casting is a high-pressure casting process where molten metal is injected into robust, precisely machined steel dies under extreme pressure. These dies are typically made from hardened tool steel and are designed for very high-volume production.

Typical Types of Die Casting Molds (based on alloy/process):

- Hot-Chamber Dies: Used for low-melting-point alloys like zinc, tin, and lead. The injection mechanism is submerged in the molten metal. Dies typically made from general tool steels.

- Cold-Chamber Dies: Used for higher-melting-point alloys like aluminum, magnesium, and copper (Brass casting molds). Molten metal is ladled into a separate shot chamber. Dies require higher strength and heat resistance (e.g., H13 tool steel for aluminum casting molds).

Impact on Part Quality:

The combination of high pressure, rapid injection, and robust, temperature-controlled steel dies results in exceptionally high quality for specific part types, but with unique challenges.

| Quality Parameter | Hot-Chamber Dies (e.g., Zinc) | Cold-Chamber Dies (e.g., Aluminum) |

| Surface Finish (Ra) | Outstanding (0.8 to 1.6μm); often mirror-like, direct-use finish. | Excellent (1.6 to 3.2μm); very smooth, minimal finishing needed. |

| Dimensional Acc. (ISO CT) | Highest (CT4-CT5); exceptional precision, repeatable. | Very High (CT5-CT6); extremely precise, repeatable. |

| Internal Defects | Low gas porosity (less turbulent fill than cold-chamber); very dense. | Prone to gas porosity (most significant concern due to turbulent fill); can blister during heat treatment; potential for cold shuts and flash. |

| Mechanical Properties | High strength, hardness, and density due to fine grain structure. Excellent ductility for zinc. | High strength and hardness due to very fine grain structure (chill zone); overall properties can be compromised by internal porosity if not controlled. |

| Complexity & Detail | Unmatched for intricate, thin-walled geometries (e.g., 0.3 mm wall thickness). | Unmatched for intricate, thin-walled geometries (e.g., 0.5 mm wall thickness). |

| Alloys Typically Cast | Zinc, Tin, Lead alloys. | Aluminum, Magnesium, Copper alloys (Brass casting molds less common due to die wear/cost). |

| Die Life | Very long (hundreds of thousands to millions of shots). | Long (tens of thousands to hundreds of thousands of shots, but less than hot-chamber due to higher temperatures and wear). |

| Cycle Time | Extremely fast (seconds per part). | Very fast (seconds to minutes per part). |

| Cost | Very high upfront tooling cost; extremely low per-part cost for mass production. | Very high upfront tooling cost; extremely low per-part cost for mass production. |

Specific Considerations for Different Metal Alloys

Different alloys have unique thermal and mechanical properties, influencing mold material selection:

| Metal Alloy | Preferred Mold Material | Reason |

| Aluminum | Steel, Graphite, Sand | High thermal conductivity, avoids shrinkage |

| Brass | Cast Iron, Steel | Resistant to abrasion, high temperature |

| Stainless Steel | Ceramic, Graphite | Withstands high melting points |

| Bronze | Sand, Graphite | Handles moderate temperatures effectively |

Selecting the appropriate mold material ensures the alloy’s properties are preserved while maintaining dimensional accuracy.

Factors Beyond Material: Mold Design and Process Control

The quality of the final part isn’t solely dependent on the mold material. Other factors include:

- Mold Design: Proper gating and venting prevent defects like porosity or inclusions.

- Process Control: Maintaining consistent temperatures and solidification rates ensures uniformity.

- Maintenance: Regular inspection and cleaning of molds prolong lifespan and prevent contamination.

The choice of casting mold material profoundly affects the quality of the finished part. From sand molds for flexibility to permanent molds for precision and repeatability, each material offers unique benefits and trade-offs. By carefully considering the alloy being cast, production volume, and application requirements, manufacturers can optimize part quality and cost-efficiency. Mold material, paired with sound design and process control, is a decisive factor in achieving excellence in casting.