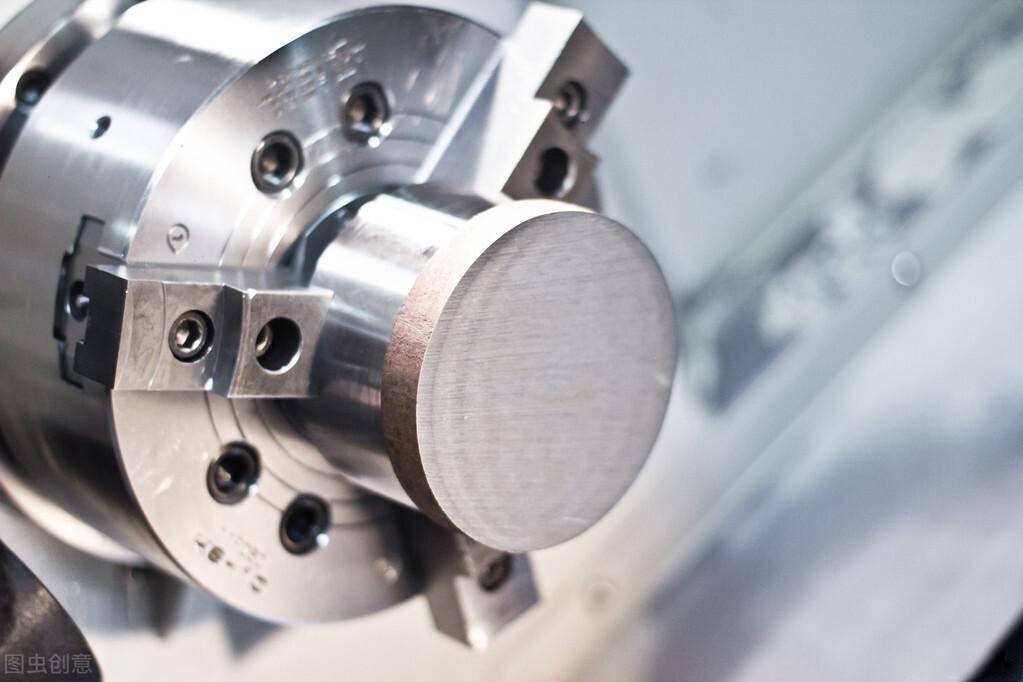

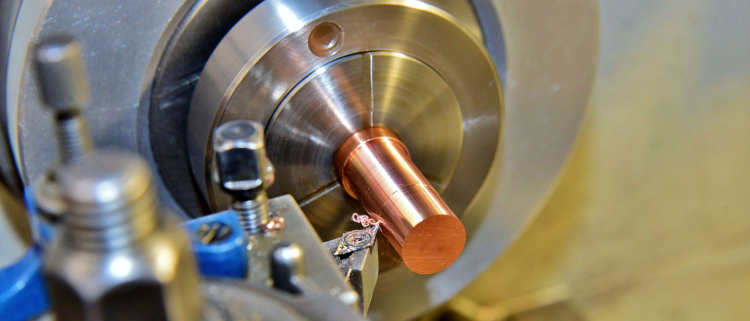

The environmental effects of manufacturing processes are being examined more closely in today’s eco-aware society. The use of rotating cutting tools in CNC milling, a computer-controlled manufacturing process that removes material from a workpiece, is becoming more environmentally friendly and sustainable than traditional manufacturing techniques. This article explores the advantages of CNC milling for the environment, emphasizing how it reduces material waste, energy use, and dependency on hazardous materials.

Advantage 1: Reduced Material Waste

CNC milling is thought to have several environmental advantages, including reduced material waste because of its capacity to maximize raw material utilization and reduce waste generation. CNC milling provides exact control over tool movement and cutting parameters, leading to a more efficient and waste-conscious production process than traditional manufacturing methods, which frequently involve significant material loss during the cutting process. Reduced material waste is one of CNC milling’s main environmental advantages for the following reasons:

- Resource Conservation: CNC milling contributes to the preservation of valuable natural resources by minimizing waste and lowering the need for excessive extraction and processing of raw materials. This resource conservation helps to ensure long-term sustainability while also being good for the environment.

- Environmental Impact Reduction: A smaller environmental impact is directly related to the decreased waste produced by CNC milling. With less waste, less landfill space is needed, and disposing of waste carries a lower risk of contaminating the environment.

- Cost-Effectiveness: Reduced waste also results in lower costs for manufacturers. Businesses can reduce waste disposal expenses and maximize material utilization by using less scrap material, which improves overall efficiency.

- Promoting Sustainable Practices: The capacity of CNC milling to minimize material waste is consistent with sustainable manufacturing principles, which prioritize resource efficiency, environmental preservation, and economic feasibility.

Advantage 2: Reduced Energy Consumption

CNC milling is considered an environmentally friendly manufacturing method due to its reduced energy consumption compared to traditional manufacturing techniques. Here are some key reasons why CNC milling offers energy efficiency advantages:

- Optimized Toolpath Planning: Precise toolpaths that minimize pointless movements and maximize cutting patterns are programmed into CNC machines. As a result, less energy is needed overall for the machining process.

- Precise Cutting Operations: Only the necessary material is removed thanks to the accurate and controlled cutting operations carried out by CNC milling machines. As a result, there is less material waste and less energy needed to make the finished product.

- Automated Processes: Several manufacturing processes are automated by CNC milling, which removes the need for human intervention. As a result, production runs can be completed more quickly and with less energy used for manual labor.

- Spindle Speed and Feed Rate Optimization: Depending on the material of the workpiece and the requirements for machining, CNC machines can maximize feed rates and spindle speed. By optimizing, the machine is guaranteed to run at its most energy-efficient levels.

- Regenerative Braking Systems: Regenerative braking systems are employed by certain CNC machines, which seize energy from decelerations and retain it for future use in machining operations. This improves energy efficiency even more.

- IDLE State Power Management: When the machine is not actively machining, idle state power management systems on CNC machines often lower power consumption. This further reduces the need for energy.

- Hybrid Machine Designs: A rising trend in CNC machines is hybrid models that integrate renewable energy sources like solar or wind power with traditional machining. In turn, this lessens the need for the negative environmental effects of traditional power sources.

Advantage 3: Improved Product Quality

One of the environmental advantages of CNC milling is thought to be better product quality because it can minimize material waste, cut down on scrap and rework, and increase product lifespan. This is a thorough explanation:

- Minimized Rework and Scrap: The exact control of CNC milling produces tight tolerances and consistent dimensional accuracy, which reduces the number of non-conforming or defective parts. Rework and scrap are reduced, which lessens the need for extra material consumption and machining operations and reduces the environmental impact even more.

- Extended Product Lifespan: The longevity of final products is increased by CNC milling’s capacity to create strong, long-lasting parts. As a result, there is less of an overall environmental impact from material extraction, manufacturing, and disposal, and product replacement frequency is decreased.

Conclusion

In the manufacturing sector, CNC milling is a shining example of sustainability because it provides several environmental advantages over conventional techniques. Because of its capacity to lower energy usage, material waste, and dependency on hazardous materials, it is an attractive option for manufacturers looking to reduce their environmental impact. Chongqing Jin Te Rui Machine Co., Ltd. is a proficient manufacturer committed to providing CNC milling services. CNC milling is going to be more and more important in creating a more sustainable manufacturing environment as environmental concerns grow.