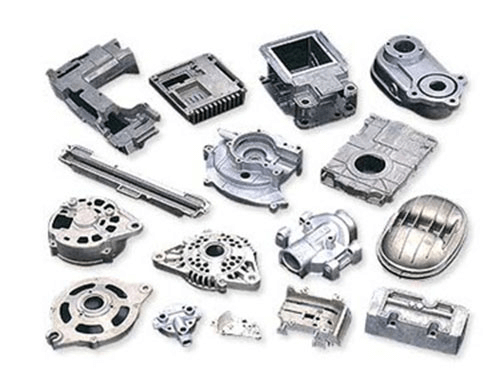

Aluminum die casting is a versatile manufacturing process that offers numerous advantages, including high dimensional accuracy, excellent surface finish, and the ability to create complex shapes with precision. One crucial factor that significantly influences the selection and application of aluminum in die casting is its strength-to-weight ratio. The strength-to-weight ratio measures the load-bearing capacity of a material relative to its weight and plays a pivotal role in determining the suitability and performance of aluminum components in various industries.

In this article, we will explore the impact of the strength-to-weight ratio factor on aluminum die casting. Hope it will help you choose the right Aluminum die-casting part.

What is the strength-to-weight ratio and how to calculate it?

The strength-to-weight ratio is a measure of the strength or load-bearing capacity of a material relative to its weight. It quantifies how much strength or load a material can withstand per unit of weight.

To calculate the strength-to-weight ratio, follow these steps:

- Determine the strength of the material: Identify the specific strength property relevant to your application, such as tensile strength, compressive strength, or flexural strength. This information is typically obtained from material specifications or testing.

- Determine the weight of the material: Measure or determine the weight of the material. This can be done by weighing a sample or obtaining the weight from material specifications or data sheets.

- Divide the strength by the weight: Divide the strength value by the weight value. Make sure both values have consistent units for an accurate calculation. For example, if the strength is measured in newtons (N) and the weight is in kilograms (kg), the resulting strength-to-weight ratio will be expressed in newtons per kilogram (N/kg).

Strength-to-weight ratio = Strength / Weight

The higher the strength-to-weight ratio, the more efficient the material is in terms of strength relative to its weight. A higher ratio indicates that a material can handle greater loads or stresses while being relatively lightweight.

It’s important to note that the strength-to-weight ratio is a comparative measure and should be considered when comparing different materials or structures for a specific application. Additionally, the specific requirements and constraints of the application may impact the importance and interpretation of the strength-to-weight ratio.

How does the strength-to-weight ratio factor affect Aluminum Die Casting?

The strength-to-weight ratio is a crucial factor in the selection and application of aluminum die casting. Aluminum, known for its lightweight properties, is widely used in die casting due to its favorable strength-to-weight ratio. Here’s how this factor affects aluminum die casting:

- Lightweight design: Aluminum die casting allows for the production of lightweight components without compromising strength or structural integrity. The high strength-to-weight ratio of aluminum enables the manufacturing of parts that are both strong and lightweight, making it suitable for various industries, such as automotive, aerospace, and consumer electronics.

- Fuel efficiency: In industries like automotive and aerospace, reducing weight is critical to improving fuel efficiency and reducing emissions. By utilizing aluminum die casting, which offers a high strength-to-weight ratio, manufacturers can create lighter components that contribute to overall weight reduction in vehicles or aircraft. This, in turn, helps enhance fuel efficiency and performance.

- Structural integrity: Despite its lightweight nature, aluminum die casting maintains good mechanical properties and structural integrity. The high strength-to-weight ratio ensures that aluminum components can withstand the required loads and stresses, providing durability and reliability in various applications.

- Cost savings: The high strength-to-weight ratio of aluminum die casting can result in cost savings. By using lightweight aluminum components, manufacturers can reduce material costs and potentially save on transportation costs. Additionally, lightweight designs may require smaller support structures or additional components, leading to overall cost reduction.

- Design flexibility: Aluminum die casting allows for intricate and complex shapes to be easily manufactured, offering design flexibility. The high strength-to-weight ratio of aluminum allows designers to optimize the component’s shape and wall thickness, maximizing its performance while minimizing weight.

- Heat dissipation: Aluminum’s excellent thermal conductivity facilitates efficient heat dissipation. This property is particularly valuable in applications where thermal management is crucial, such as electronic components. The high strength-to-weight ratio of aluminum die casting ensures both structural integrity and efficient heat transfer.

In summary, the strength-to-weight ratio is a significant factor in aluminum die casting. It enables the production of lightweight components with excellent strength and structural integrity, contributing to fuel efficiency, cost savings, design flexibility, and efficient heat dissipation in various industries.