High-performance boats are the epitome of engineering excellence, combining speed, durability, and precision. Achieving this level of performance requires components that are manufactured to exacting standards. This is where CNC (Computer Numerical Control) machining comes into play. By utilizing CNC technology, manufacturers can produce boat components with unparalleled precision, ensuring optimal performance and longevity. This article explores the top 10 CNC machined components essential for high-performance boats, categorized by their function within the vessel.

Why CNC is Beneficial for the Marine Industry?

CNC machining has revolutionized the marine industry by providing a means to produce components with exceptional accuracy and consistency. Here are a few reasons why CNC is particularly beneficial for high-performance boating:

- Precision: CNC machines operate with tight tolerances, ensuring that each component is manufactured to exact specifications. This precision is critical for components that must fit perfectly and operate efficiently under high stress and speed.

- Consistency: Once a design is programmed into a CNC machine, it can produce identical parts repeatedly, ensuring consistency across all manufactured components. This uniformity is essential for maintaining the reliability and performance of high-performance boats.

- Customization: CNC machining allows for the creation of custom components tailored to specific needs. This capability is crucial for high-performance boats, where bespoke solutions can provide a competitive edge.

- Material Versatility: CNC machines can work with a wide range of materials, including metals, plastics, and composites. This versatility allows for the selection of optimal materials for each component based on strength, weight, and corrosion resistance.

10 CNC Machined Components for High-Performance Boats

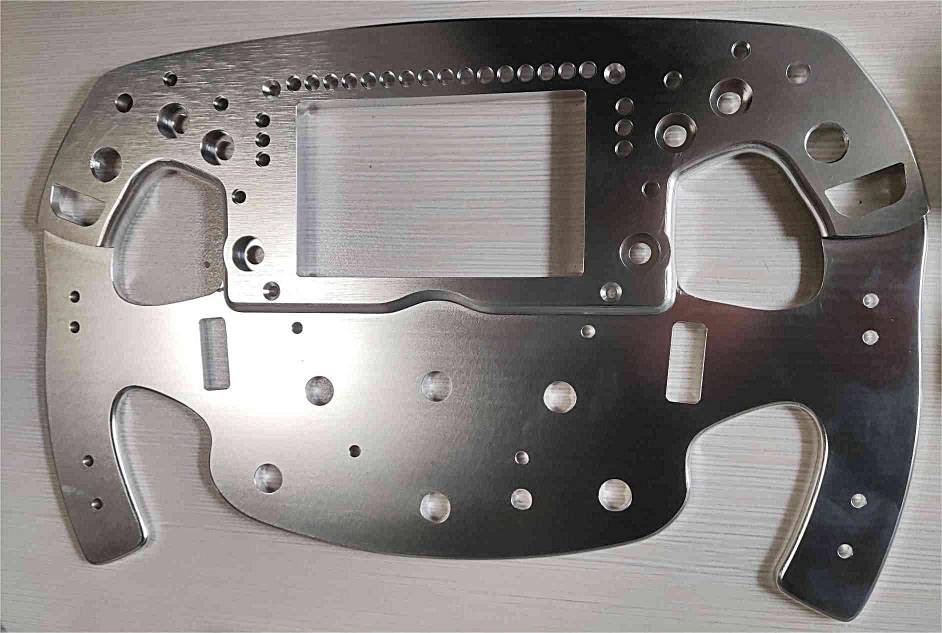

When it comes to high-performance boats, every component must be meticulously crafted to ensure optimal performance and durability. CNC machining plays a crucial role in this process by producing parts with exceptional precision and consistency. Here we delves into the top 10 CNC machined components that are essential for high-performance boats, categorized into engine, drivetrain, control, and weight reduction and customization components. Each of these parts is engineered to meet the stringent demands of high-speed marine environments, enhancing the overall efficiency, reliability, and speed of the vessel.

| Category | Component Name |

| Engine Components | Cylinder Heads |

| Pistons | |

| Drivetrain Components | Propeller Shafts |

| Gearboxes | |

| Control Components | Throttle Bodies |

| Steering System Components | |

| Weight Reduction and Customization Components | Custom Hull Fittings |

| Aluminum or Titanium Fasteners | |

| Deck Hardware | |

| Custom Interior Components |

Engine Components

- Cylinder Heads

CNC machining of cylinder heads ensures extremely tight tolerances and smooth surfaces, which are crucial for optimal airflow and combustion. This precision machining process allows for intricate designs that improve the flow of air and fuel into the combustion chamber and the evacuation of exhaust gases.

Benefit: Improved airflow leads to more efficient combustion, resulting in increased power output, better fuel efficiency, and lower emissions. Additionally, CNC machined cylinder heads enhance the engine’s reliability and longevity by ensuring uniform thermal expansion and reducing the risk of warping.

- Pistons

Custom machined pistons are tailored to the specific requirements of the engine, allowing for precise control over compression ratios and combustion dynamics. CNC machining enables the creation of pistons with complex geometries and fine surface finishes that would be difficult to achieve with other manufacturing methods.

Benefit: The enhanced precision and customization result in increased power output, improved fuel efficiency, and greater durability under high-performance conditions. Custom pistons can also reduce engine knock and improve overall engine smoothness.

Drivetrain Components

- Propeller Shafts

CNC machining ensures that propeller shafts are manufactured with high precision, resulting in optimal alignment and balance. This precision is crucial for minimizing vibration and ensuring smooth rotation at high speeds.

Benefit: Enhanced propulsion efficiency due to reduced friction and vibration, which also contributes to the longevity of the drivetrain components. Precise machining reduces the risk of mechanical failure, leading to a more reliable and efficient propulsion system.

- Gearboxes

Gearbox components, such as gears and housings, are CNC machined to achieve exacting tolerances and surface finishes. This precision is necessary to handle the high loads and stresses encountered in high-performance marine applications.

Benefit: Reliable power transmission and enhanced durability under high loads. Precision machining ensures smoother gear transitions, reducing wear and tear on components and improving overall drivetrain performance and lifespan.

Control Components

- Throttle Bodies

CNC machined throttle bodies allow for precise control over air intake, which is essential for fine-tuning engine performance. The smooth and accurate surfaces achieved through CNC machining ensure optimal airflow and responsiveness.

Benefit: Improved throttle response, leading to better acceleration and more precise control over engine power output. This contributes to overall engine efficiency and performance, particularly in high-demand situations.

- Steering System Components

Components such as steering arms, linkages, and rudder mechanisms are CNC machined for exact fit and high strength. This precision ensures that the steering system operates smoothly and reliably under varying conditions.

Benefit: Enhanced handling and control of the boat, providing a more responsive and safer steering experience. Precise components reduce the play and potential for failure, contributing to overall safety and performance.

Weight Reduction and Customization Components

- Custom Hull Fittings

CNC machining allows for the creation of custom hull fittings, such as cleats, fairleads, and railings, which are lightweight and corrosion-resistant. These components can be precisely tailored to the boat’s design and specifications.

Benefit: Weight reduction leads to improved speed and fuel efficiency. Custom fittings also enhance the boat’s aesthetics and can be designed to integrate seamlessly with the boat’s overall design, improving functionality and appearance.

- Aluminum or Titanium Fasteners

High-performance fasteners made from materials like aluminum or titanium are CNC machined to exact specifications. These fasteners provide the necessary strength while significantly reducing weight.

Benefit: The use of lightweight, high-strength fasteners reduces the overall weight of the boat, contributing to increased speed and better fuel efficiency. The strength of these materials ensures durability and reliability in harsh marine environments.

- Deck Hardware

CNC machining produces custom deck hardware, including winches, blocks, and fairleads, optimized for strength and weight reduction. These components are essential for handling rigging and deck operations.

Benefit: Enhanced functionality and efficiency in handling deck operations, with the added benefit of weight savings. Custom hardware ensures that the components are tailored to specific performance requirements, improving both usability and performance.

- Custom Interior Components

CNC machining allows for the production of bespoke interior components such as consoles, seating frames, and storage solutions. These components can be designed for maximum weight reduction and aesthetic appeal.

Benefit: Personalized customization enhances the overall user experience and comfort. Weight reduction in interior components contributes to the boat’s overall performance, improving speed and fuel efficiency. Custom designs also ensure that the interior meets the specific needs and preferences of the boat owner.

Conclusion

CNC machining is a game-changer for the marine industry, offering precision, consistency, and customization that are essential for high-performance boats. By incorporating CNC machined components, manufacturers can significantly enhance the performance, reliability, and efficiency of their vessels. From engine and drivetrain components to control and weight reduction elements, CNC technology ensures that high-performance boats meet the demanding standards of speed and durability. As the marine industry continues to evolve, CNC machining will remain at the forefront of innovation, driving the creation of even more advanced and capable high-performance boats.