In the world of manufacturing and design, surface treatment plays a crucial role in enhancing both aesthetics and functionality. Among the myriad of surface treatment options available, black anodized aluminum stands out as a timeless choice, offering enduring beauty and versatility for a wide range of projects. This article delves into the intricacies of black anodized aluminum, exploring its properties, applications, and why it remains a popular option across industries.

What is Black Anodizing?

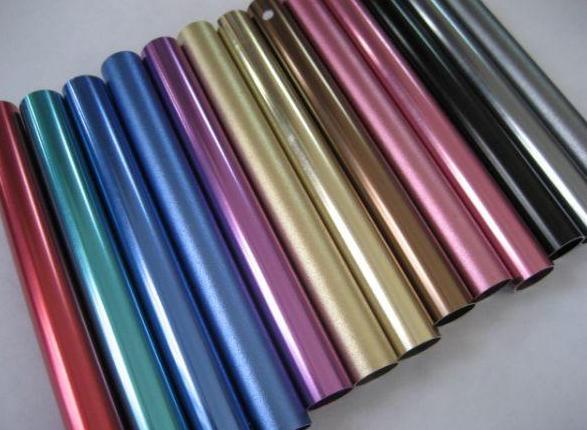

Anodizing is a process used to increase the thickness of the natural oxide layer on the surface of metal parts, primarily aluminum. This electrochemical process not only enhances corrosion resistance but also provides an opportunity to introduce various colors, including black, to the metal’s surface.

The black anodizing process involves immersing aluminum parts in an electrolytic solution and passing an electric current through it. This results in the formation of a thicker layer of oxide on the surface, which can then be dyed black using organic or inorganic dyes. Finally, the parts are sealed to lock in the color and enhance durability.

Why Choose Black Color for Anodized Aluminum?

Choosing black color for anodized aluminum offers numerous advantages, making it a popular choice across various industries. Here are several reasons why black anodized aluminum is preferred:

- Visual Appeal: Black anodized aluminum exhibits a deep, rich black color with a matte finish that exudes elegance and sophistication. This visually striking appearance adds a touch of class to products, enhancing their overall aesthetic appeal.

- Perception of Quality: The black color imparts a sense of durability, premium quality, and sophistication to aluminum components. This perception of high quality can elevate the perceived value of products, making them more desirable to consumers.

- Versatility: Black anodized aluminum complements a wide range of design styles, including modern, industrial, minimalist, and contemporary. Its neutral yet bold appearance allows it to seamlessly integrate into various design schemes, providing designers with flexibility and versatility.

- Reduced Glare and Reflection: The matte finish of black anodized aluminum minimizes glare and reflections, making it ideal for applications where excessive light reflection could be a concern. This characteristic enhances visibility and readability in environments with varying lighting conditions.

- Hide Surface Imperfections: The dark color of black anodized aluminum can help conceal minor surface imperfections or blemishes, providing a more uniform and aesthetically pleasing appearance compared to lighter colors.

- Heat Dissipation: Black anodized aluminum has relatively high emissivity, meaning it can effectively dissipate heat. This makes it suitable for applications where thermal management is important, such as in electronic devices or heat sinks.

- Corrosion Resistance: Like other types of anodized aluminum, black anodized aluminum offers enhanced corrosion resistance due to the thick oxide layer formed during the anodizing process. This protective layer helps to prevent oxidation and corrosion, prolonging the lifespan of the aluminum component.

- Environmentally Friendly: Anodizing is an environmentally friendly surface treatment process that does not involve the use of heavy metals or toxic chemicals. The resulting black anodized aluminum is durable, non-toxic, and recyclable, making it a sustainable choice for manufacturers and consumers alike.

Overall, the black color of anodized aluminum offers a combination of aesthetic appeal, durability, versatility, and performance, making it an attractive choice for a wide range of applications in industries such as automotive, architecture, consumer electronics, aerospace, and more.

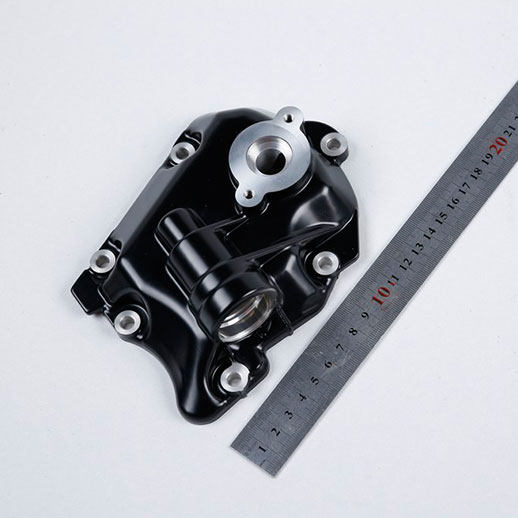

Applications of Black Anodized Aluminum

Black anodized aluminum parts are commonly used in various industries due to their aesthetic appeal, corrosion resistance, and durability. This table provides a structured overview of the applications of black anodized aluminum, along with the advantages and typical parts associated with each application.

| Application | Advantages | Typical Parts |

| Aerospace Components | Lightweight, corrosion resistance, durability | Brackets, housings, panels, structural elements |

| Automotive Parts | Aesthetic appeal, corrosion resistance, durability, lightweight | Interior trim pieces, dashboard accents, door handles |

| Consumer Electronics | Scratch resistance, sleek appearance, corrosion resistance, lightweight | Casings, frames, bezels, housing components |

| Firearms and Weapon Accessories | Lightweight, corrosion resistance, durability, scratch resistance | Receivers, handguards, scope mounts |

| Industrial Equipment | Durability, professional appearance, corrosion resistance, lightweight | Machine frames, enclosures, brackets, heat sinks |

| Medical Devices | Biocompatibility, corrosion resistance, ease of sterilization, lightweight | Surgical instruments, diagnostic equipment, prosthetic components |

| Sporting Goods | Lightweight, weather resistance, corrosion resistance, durability | Bicycle frames, fishing reel components, camping cookware |

Overall, the applications of black anodized aluminum are diverse, spanning multiple industries where its unique combination of properties meets specific performance requirements.

Conclusion

Black anodized aluminum offers a perfect blend of beauty and functionality. Whether you’re a designer seeking a sophisticated finish for your project or an engineer requiring a durable material, black anodized aluminum offers a compelling solution. With its timeless design, superior strength, and versatility, black anodized aluminum is sure to enhance any project.