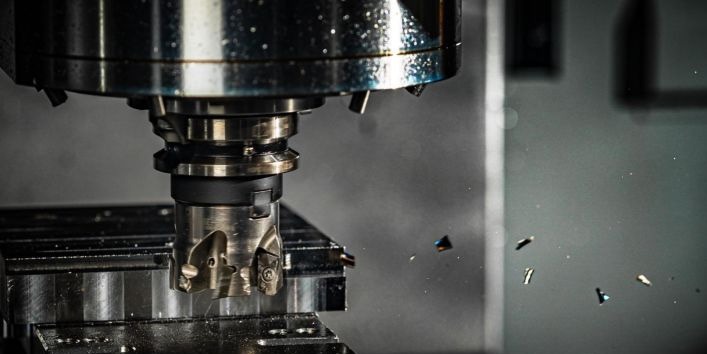

CNC bronze and brass machining are subtractive manufacturing processes that use computer-controlled machines to cut and shape bronze and brass alloys. Both processes are highly versatile and can be used to create a wide range of parts, from simple to complex, with high precision and accuracy.

Brass is an alloy of copper and zinc, while bronze is an alloy of copper and tin. Both materials are known for their good strength, wear resistance, and corrosion resistance. However, they have some key differences in terms of their machinability and properties.

Differences Between Bronze and Brass CNC Machining

CNC bronze and brass are both copper alloys, but they have different properties and applications.

- Composition:

Bronze can also contain other alloying elements, such as lead, aluminum, and silicon.

Brass can also contain other alloying elements, such as lead, nickel, and manganese.

- Properties:

- Strength: Bronze is generally stronger and more wear-resistant than brass.

- Corrosion resistance: Bronze is also more corrosion-resistant than brass, especially in saltwater environments.

- Ductility: Brass is more ductile than bronze, meaning it can be more easily formed into complex shapes.

- Electrical conductivity: Brass is also a better conductor of electricity than bronze.

- Applications:

Bronze is often used in applications where strength, wear resistance, and corrosion resistance are important, such as bearings, bushings, and gears.

Brass is often used in applications where ductility, electrical conductivity, and machinability are important, such as electrical connectors, musical instruments, and plumbing fittings.

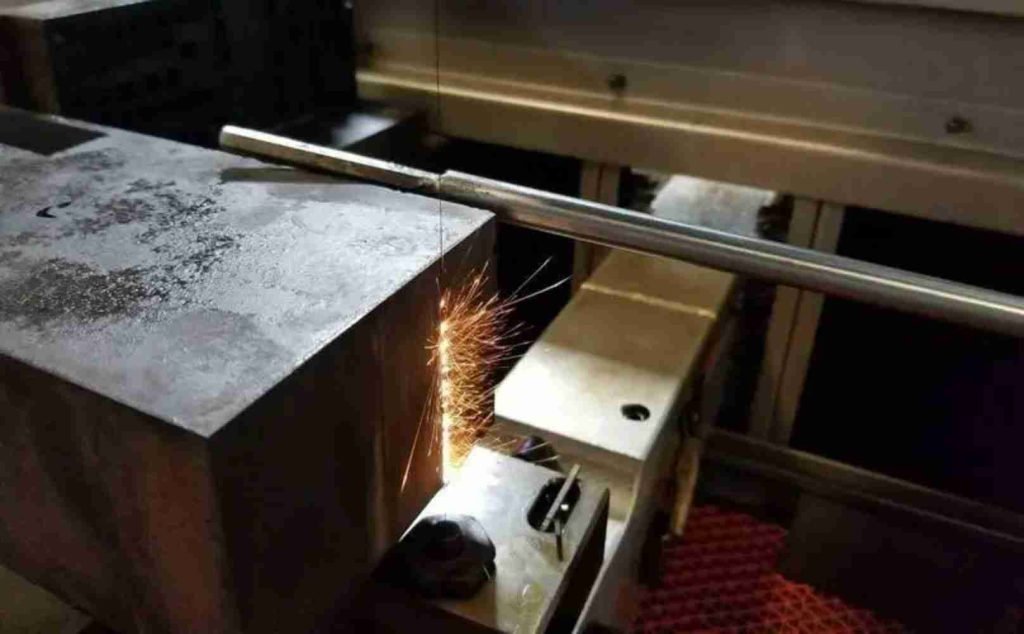

- CNC machining:

Both bronze and brass are good materials for CNC machining. However, bronze is generally more difficult to machine than brass due to its higher hardness and strength.

Here is a table summarizing the key differences between CNC bronze and brass:

| Property | CNC bronze | CNC brass |

| Composition | Copper and tin | Copper and zinc |

| Strength | Higher | Lower |

| Wear resistance | Higher | Lower |

| Corrosion resistance | Higher | Lower |

| Ductility | Lower | Higher |

| Electrical conductivity | Lower | Higher |

| Machinability | More difficult | Easier |

| Applications | Bearings, bushings, gears, etc. | Electrical connectors, musical instruments, plumbing fittings, etc. |

Typical Bronze and Brass Precision Turned Components

Bronze Precision Turned Components:

- Bushings: Bushings are used to reduce friction and wear between moving parts. They are typically made from bronze because of its good wear resistance and self-lubricating properties.

- Gears: Gears are used to transmit power between two rotating shafts. They are typically made from bronze because of its strength and wear resistance.

- Bearings: Bearings are used to support rotating shafts and reduce friction. They are typically made from bronze because of its good wear resistance and self-lubricating properties.

- Electrical contacts: Electrical contacts are used to make and break electrical circuits. They are typically made from bronze because of its good conductivity and corrosion resistance.

- Heat sinks: Heat sinks are used to dissipate heat from electronic components. They are typically made from bronze because of its good thermal conductivity.

Brass Precision Turned Components:

- Fittings: Fittings are used to connect pipes and tubes. They are typically made from brass because of its good corrosion resistance and machinability.

- Valves: Valves are used to control the flow of fluids. They are typically made from brass because of its good corrosion resistance and machinability.

- Connectors: Connectors are used to connect electrical and electronic components. They are typically made from brass because of its good conductivity and corrosion resistance.

- Electrical terminals: Electrical terminals are used to connect electrical wires to components. They are typically made from brass because of its good conductivity and corrosion resistance.

- Screws and nuts: Screws and nuts are used to fasten two or more pieces of material together. They are typically made from brass because of its good strength and machinability.

Which Material is Right for You?

The best material for your CNC machining project will depend on your specific needs. If you need a material that is strong, wear-resistant, and corrosion-resistant, then CNC bronze is a good choice. If you need a material that is ductile, electrically conductive, and easy to machine, then CNC brass is a good choice.

If you are still unsure which material is right for you, please consult with a CNC machining expert – JTR – Providing Professional CNC machining in China. Feel free to contact them and you will get the best service and products.