Precision Machining: Exploring the World of CNC Small Parts Manufacturing

In the intricate realm of manufacturing, precision holds the key…

In the intricate realm of manufacturing, precision holds the key…

Wire Electrical Discharge Machining (Wire EDM) is a powerful and…

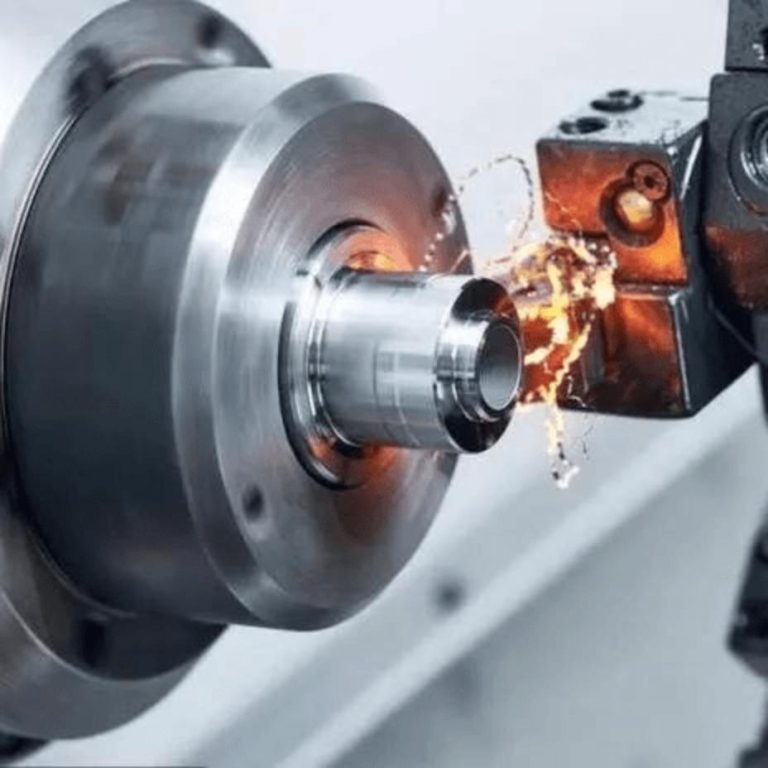

A computer program controls a machine to precisely cut, shape,…

The world of manufacturing is constantly evolving, with technology pushing…

CNC machining, also known as computer numerically controlled machining, is a…

6061 T6 aluminum reigns supreme as the go-to material for countless…

CNC machining is becoming the preferred method for producing strong, complex parts,…

Aluminum can be manufactured with great versatility and precision through…

CNC machining is a cornerstone in the manufacturing industry, demonstrating the…

CNC machining has revolutionized manufacturing by enabling precise and efficient…

The Significance of Aluminum in CNC Machining CNC machining, an…

CNC machining, a cornerstone of modern manufacturing, relies heavily on…

Request A Quote