The jewelry processing technology is a general term for all the processes of processing various jewelry raw materials according to various forms to form finished products. Specifically, it includes manual processing technology, machine processing technology, and surface finishing technology of precious metal jewelry. This article will take you to understand how to use CNC machining to make jewelry crafts.

Methods & Types of Jewelry Processing

1. The processing technology of jewelry can be divided into two categories: precious metal jewelry processing technology and gem setting technology.

2. Precious metal processing technology can be divided into traditional manual processing technology, machine processing technology, and surface treatment technology.

3. The traditional manual processing technology mainly includes filigree technology, the machine processing technology includes lost wax casting technology, stamping technology, machine chain technology, etc., and the surface treatment technology includes electroplating technology and embossing technology.

Types of Jewelry Processing

1. Manual processing technology – filigree technology

Filigree technology refers to the fine gold craftsmanship that uses metal filaments to make shapes using coiling, pinching flowers, silk, and stacking.

During production, firstly, metal such as gold or silver is drawn into wires of the required thickness, and then the drawn wires are twisted together (called twisting filigree in the industry). Parts of various shapes are gathered together, sprinkled with solder powder, and overheated, that is, welded together to form a certain overall shape.

This overall shape is called “black tire”. After the black tire is washed with dilute acid, it must be subjected to subsequent processing such as silvering, blue burning, gold plating, or silver plating, and finally becomes a finished product. Filigree jewelry is slender, delicate, full of connotation, and has an excellent myopia effect.

2. CNC machining jewelry process

(1) Lost wax casting process

Lost wax casting is the most critical production process in today’s jewelry industry, and jewelry made from lost wax casting has also become the mainstream product of today’s jewelry. The casting process is suitable for the shape of jewelry with obvious concave and convex and can be produced in large quantities.

The process of the lost wax casting process is: making a metal model – pressing plastic mold – injecting wax mold – planting a wax tree – pouring plaster mold – casting.

(2) Stamping process

The stamping process, also known as die stamping and embossing, is a manufacturing process for embossed patterns. The steps are as follows: firstly, a mold is formed according to a master, and then an embossed pattern is made on the metal by pressure. Stamping process: embossing the pattern, forming (bending), joining the joints together (usually with solder).

The stamping process is suitable for jewelry with bumps on the bottom surface, such as small lock pieces, or items with insignificant undulations that are easy to be stamped or combined in two or more steps. In addition, extremely thin parts and jewelry that require delicate detailed patterns also need to be used—stamping process processing.

(3) Machine chain processing technology

Machine chain processing technology refers to the method of mechanically processing chain accessories. Everyday necklaces such as Venetian chains, bead chains, and fringe chains are all machined.

The main process flow of machine chain processing is: wire drawing – chain making – welding – surface treatment – assembly – cleaning.

The machine chain process is characterized by large processing batches, high efficiency, many styles, and good quality. The necklace jewelry in the market today has almost been occupied by the mechanism necklace.

3. Surface finishing process of precious metal jewelry

Precious metal jewelry is surface finishing in the final stage of its production to achieve the desired artistic effect. There are many surface treatment methods, mainly including engraving, gold coating, electroplating, turning (milling), sandblasting, and so on.

(1) Electroplating process

The electroplating process is a processing method for the surface coating of precious metal jewelry, such as gold plating for silver jewelry, rhodium plating for platinum jewelry, etc. The main process of the jewelry electroplating processing method is acid-base washing – degreasing and polishing – electroplating. The electroplating process can protect the surface color and brightness of precious metal jewelry so that the jewelry has a more beautiful appearance.

(2) Gold wrapping process

The gold-clad process is to wrap the hammered gold foil layer by layer on a non-gold ornament, then heat it, and use a tool to firmly press the gold foil on the surface of the ornament without leaving any seams. Gold-encrusted jewelry looks like gold jewelry. Gold-clad technology is also a common method of jewelry surface treatment.

(3) Engraving process

The chisel engraving process is a process of using a chisel knife to create patterns on the surface of precious metals with a hammer and a hammer.

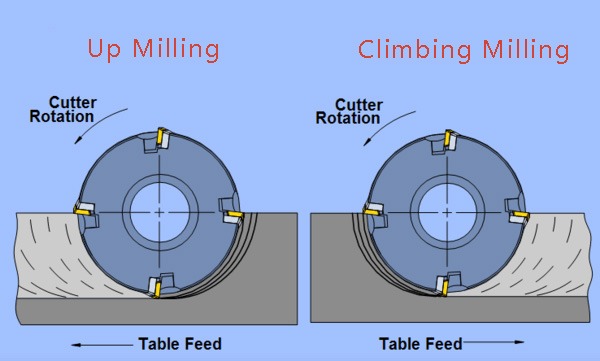

(4) CNC Turning (CNC milling)

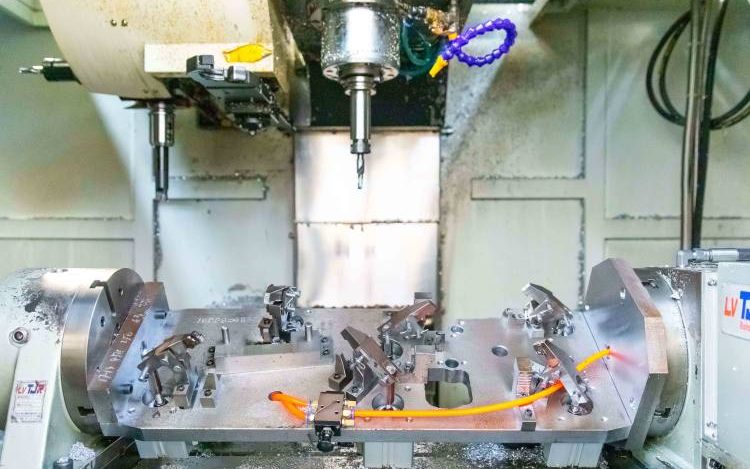

Using a high-speed rotating diamond milling cutter, the process of carving bright horizontal and vertical stripes on the surface of the ornaments and arranging them into patterns is called CNC turning or CNC milling. Because the diamond milling cutter is very hard, the streaks milled out are smooth and shiny. The so-called flashing ring or flashing pendant is processed by the car flower process and is very popular.

(5) Sandblasting

High pressure blasting fine quartz sand onto exposed polished metal surfaces resulting in a hazy soft finish.

Why CNC machining can make jewelry?

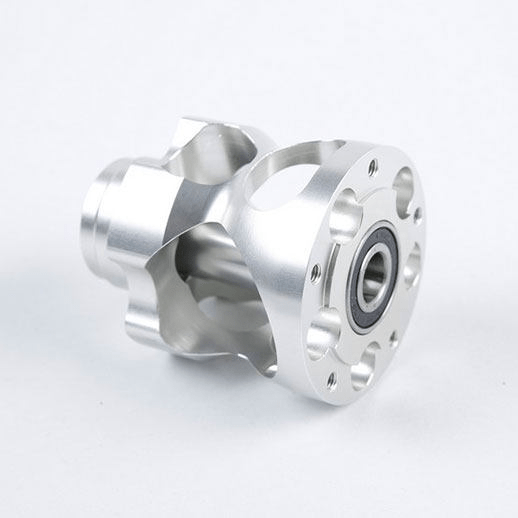

In terms of style, CNC jewelry is mainly based on regular geometric structures and abstracted and deformed animals and plants, and there are fewer natural forms such as flipping and hollowing out, to avoid excessive cutting and reduce the yield of precious metals.

In terms of ornamentation, it can be mainly divided into three types according to its formal characteristics: one is the geometric pattern formed by the combination of points, lines, and surfaces; the second is the replica depiction of the currently popular “IP”; Etiquette, Buddhist culture, etc., have been remodeled and re-innovated.

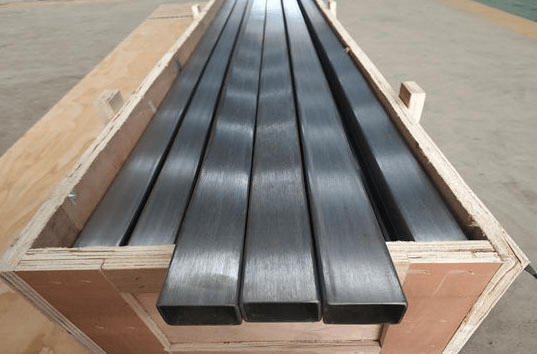

In terms of material selection, since the CNC precision machining process requires metal hardness to meet the range of precious metal hardness, except for some special texture performances that require alloys to improve the hardness of precious metals to achieve the desired effect, gold, platinum, 18k gold and various silver products have been involved.

After CNC processing metal forming, the richness of product color can be increased by post-treatment baking paint, electroplating, enameling, etc., to achieve the expected sensory effect.

Advantages of CNC machining jewelry

It is worth mentioning that the application of CNC technology provides a great development space for the design of jewelry functional structure, which puts forward higher requirements for jewelry design in terms of combination splicing and functional processing.

The diamond-encrusted process, which is very common nowadays, has the effect of multiplying the diamonds while improving the aesthetics. The “car flower piece” here refers to the process of “turning process”.

The so-called “turning process”, in simple terms, is to use of CNC technology to cut metal planes of different angles, each plane is cut at the angle of the diamond’s cutting refraction surface, and the mirror surface like a diamond is polished, showing the same refraction effect like a diamond. Ultimately play the purpose of enlarging the diamond.

The precision of this process is unimaginable in the era of manual manufacturing. The designer takes advantage of the CNC process to realize innovation in product structure from the perspective of product functionality.