Cutting-Edge Solutions: Applications of 5-Axis CNC Machining in Modern Industries

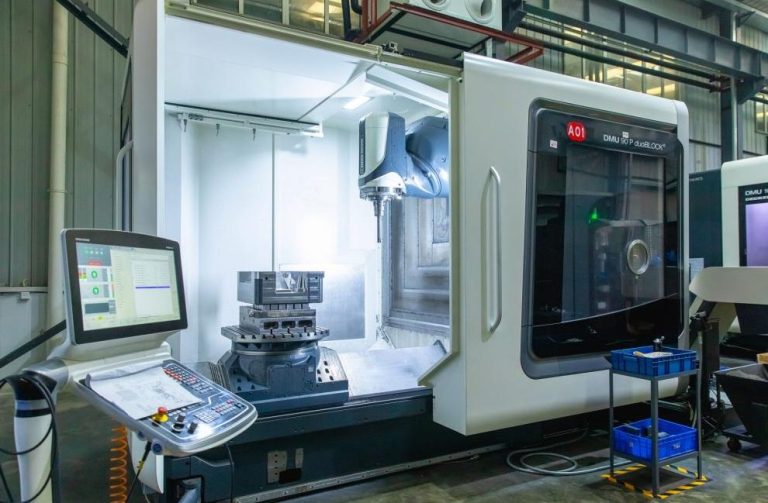

5-axis CNC machining is revolutionizing how manufacturers across various industries design,…

5-axis CNC machining is revolutionizing how manufacturers across various industries design,…

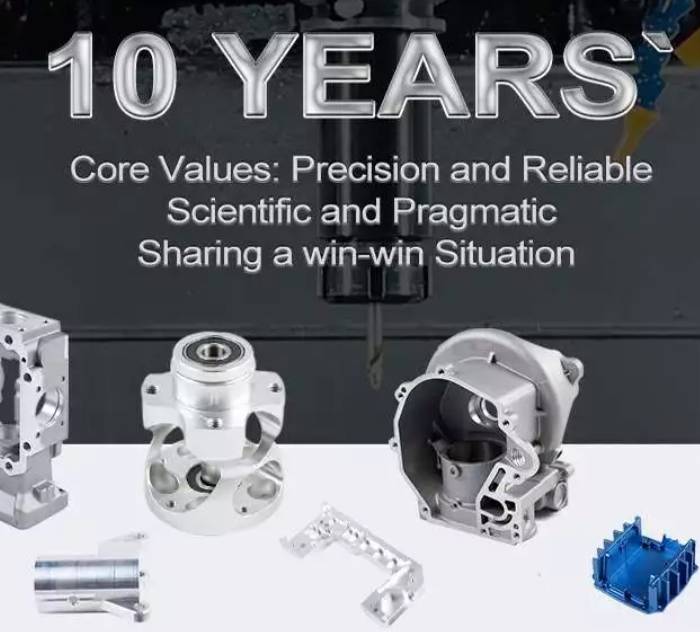

In the dynamic realm of manufacturing, striking the perfect balance…

In the world of manufacturing and engineering, precision is paramount….

In the ever-evolving landscape of manufacturing, precision and quality are…

CNC bronze and brass machining are subtractive manufacturing processes that use…

In the world of manufacturing, precision is paramount. Products are…

CNC machining plastic has emerged as a vital process in the…

CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry by…

Aluminum machining is a versatile process that can be used to…

In the world of manufacturing, the choice of the right…

In the dynamic and demanding field of aerospace engineering, materials…

CNC machining is a widely utilized manufacturing process that enables…

Request A Quote