When an engineer named ChuckHall started having the idea to print 3D objects in the 1980s, it all seemed like science fiction. But since then, 3D printing has not only become a reality step by step, but it is also a game-changer that is profoundly affecting the world, just like steam engines, electricity, and computers.

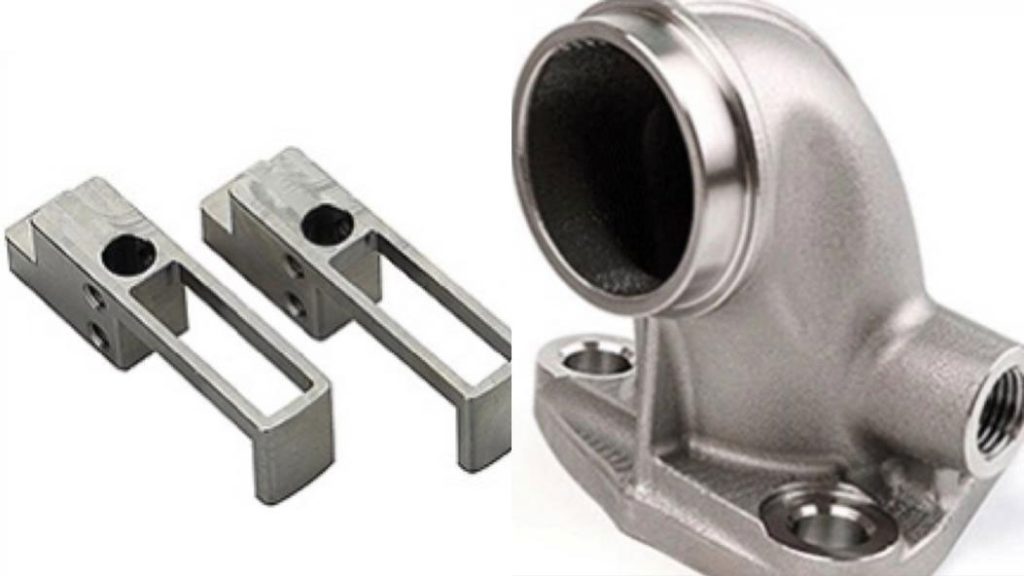

3D printers will not only greatly shorten the cycle of designing and manufacturing products in the manufacturing industry, but also facilitate the preparation of complex shapes and structures. They may even lead us into a new era of manufacturing where we don’t need factories and production lines, but instead, product designers deliver designs directly to users.

World-class companies have already embraced 3D printing technology, such as Ford using 3D printers to print engines, and General Motors plans to use it to print fuel nozzles for jet aircraft. This is just the tip of the iceberg of what 3D printers can create. Let’s examine ten ways 3D printing technology is changing the world

1. Clothing Customization

In 2013, model Lindsay Ellingson wowed visitors at the Victoria’s Secret Fashion Show wearing a pair of 3D-printed wings, a corset, and a headpiece.

But the eye-catching gimmick is just a reminder that 3D printing could transform the apparel industry. Shortly, clothing makers will use 3D scanners to scan customers’ bodies to create fitted garments and accessories that not only fit them perfectly but also adjust to the individual. “With the help of 3D printing, the freedom of the specific parts is completely up to you, such as knees or shoulders, and you just need to include these in the file.”

2. Low-cost Prosthetics

In 2012, a 14-year-old Sudanese boy, Daniel Omar, was tragically wounded in a confrontation between government forces and rebels. An American doctor managed to save a little boy’s life, but unfortunately lost his hands. It wasn’t until Mick Ebeling, the chief executive of one of the labs, learned of the difficulties faced by other Sudanese amputees in Omar.

Ebeling has set up a laboratory in a Sudanese hospital and is equipped with a 3D printer to produce prostheses that cost only $100, but traditionally manufactured prostheses are much cheaper. Researchers from Autodesk and the University of Toronto have developed software that can be used to scan a patient’s body so that it can print a prosthesis that better fits the patient.

3. Build Everything Accessories

Maybe everyone has had the experience that old appliances in the home sometimes only need to replace some parts and can work just fine. This situation is likely to improve thanks to 3D printing, which just means that you just download a drawing of the part that needs to be replaced, print it out, and replace it. Today, the 3D printing website Thingiverse offers more than 2,500 designs for replaceable parts, ranging from car window cranks, dishwashers, watch parts, and more.

4. 3D Printing for Manufacturing Medicines

With simple modifications, 3D printers can be used to eject pharmaceutical ingredients and produce chemical reactions, which will bring dawn to the pharmaceutical printing industry. In 2012, researchers at the University of Glasgow used 3D printers to print a range of medicines, including some used to treat cancer. “In the future, you can buy some regular drug, 3D print it, mix it up, and make it and get the drug you want,” explains Mark Symes. Drug DIY may reduce medical costs, but the technology still has risks, because it means people give up medical supervision. To make matters worse, law enforcement will be helpless for a certain period when it comes to downloading and printing the drug of your choice without authorization – a recent article: “In the future, your drug distributor will be the printer” published such a view.

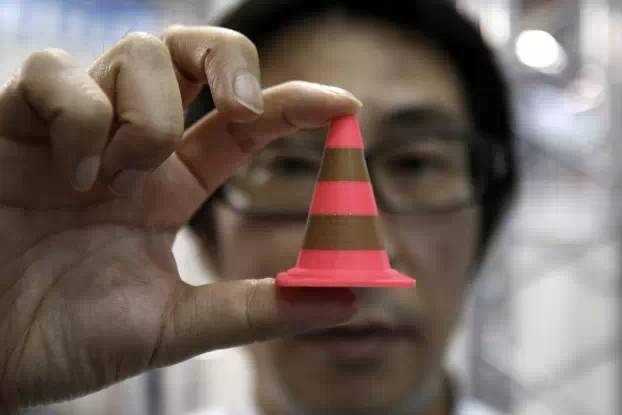

5. 3D Printing Creates Cute Candies

At the 2014 Consumer Electronics Show in Las Vegas, a company called 3D Systems showed off a pair of 3D printing systems that can make candy. Not only is the final product safe to use, but the printed candies can come in different shapes. In addition to food, a company called Nature Machines recently developed a 3D printing device called Foodini that can print wonton noodles and more.

6. 3D Printing Creates New Housing

Shortly, you will be able to create or download new designs of your own home and send them to a construction company that will build your own home for you. A Chinese construction company is using a 3D printer to print houses, spraying layers of cement and recycled construction waste to form walls and the rest of the structure. The built-to-shape home looks less glamorous, but it costs less than $5,000 to build, and the construction company claims they can produce 10 homes a day. Another Slovenian company plans to launch three different 3D house printing machines in 2014, priced at upwards of 12,000 euros.

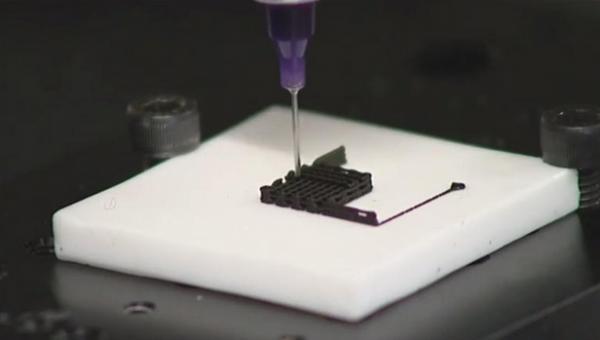

7. Organ Transplant

For years, researchers have dreamed of growing human organs in the lab so they can be transplanted to those in need. Although they have successfully grown tissue, the cellular structure of the organ and its vascular system have been very difficult to produce. At least so far. Medical researchers are making strides toward bioprinting, where they can obtain human cells from sliced tissue or stem cells, multiply them in Petri dishes, and use them as a bio link to print desired products. Scientists hope that bioprinting will one day help them precisely control cells so that they can mimic the function of human organs and be used to test new drugs or organ transplants. If the cells of an organ come from the patient’s own, the chances of it being rejected by the autoimmune system are minimal.

8. 3D Printed Car

3D-printed car parts have been around for a while, but Jim Kor and his team took a big step forward – they printed a car! The Urbee 2, a three-wheeled, two-seater car made of plastic that was widely reported in 2013, was 3D printed. The car is currently off the road as the engine is still being designed and has not been safety tested. The car took about 2,500 hours to build, but it’s a harbinger of the future — automakers could use 3D printers to make fuel-efficient cars that are as hard as steel but much lighter and Aerodynamically.

9. Copy Famous Artwork

Southern California artist Cosmo Wenman uses a 3D printer to make replicas of famous sculptures. By printing many parts, then gluing them together and painting again, he succeeded in creating the “Horse Head of Selene” – a classical Greek sculpture once in the Parthenon, now in the British Museum. Ultimately, 3D printing could help museums make copies of their collections so people around the world can enjoy them.

10. 3D Printing Firearms

In 2013, an anarchist activist in Texas created a 3D-printed pistol called the Liberator. Manufacturers were careful to incorporate metal parts to comply with federal bans—plastic pistols could pass through airport security. However, the liberators seem to be trying to show that government regulation of guns is futile because in the future it will be very easy to obtain blueprints for handguns online. Just a year later, Japanese authorities arrested a 27-year-old man for downloading a blueprint from the Internet and printing five plastic pistols. According to reports, it is only a matter of time before pistol DIYers learn to use 3D printing to create “powerful military-grade weapons.”

Summarize

3D printing is bound to spark a new revolution in our lives, it can decentralize production and facilitate innovation. If you want to have your 3D printing product, and a good idea, but cannot realize it due to no conditions, you can visit our homepage and contact us. JTR will print your product in the way that works best for you.