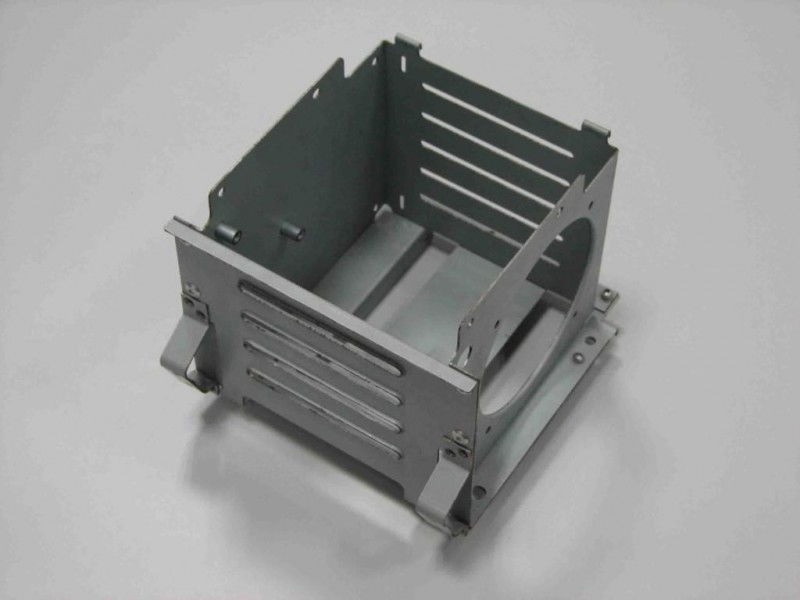

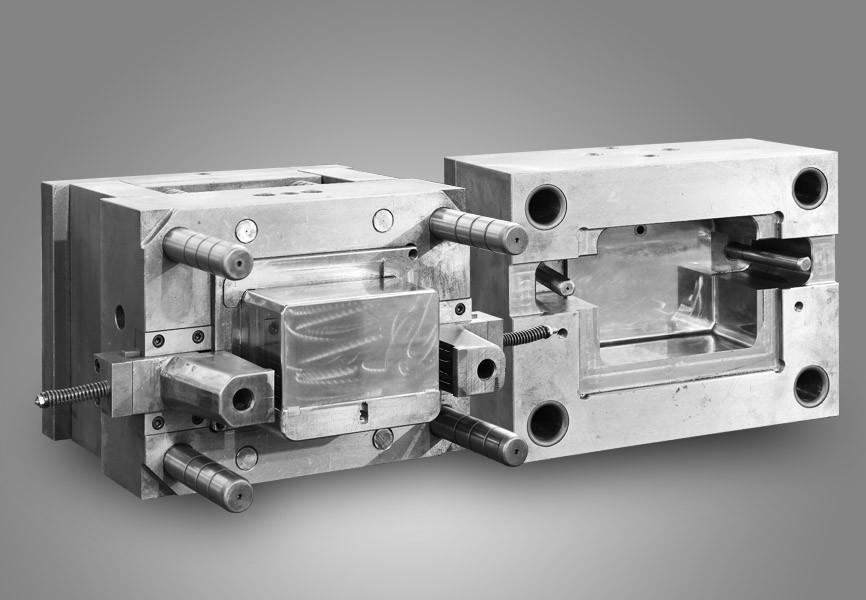

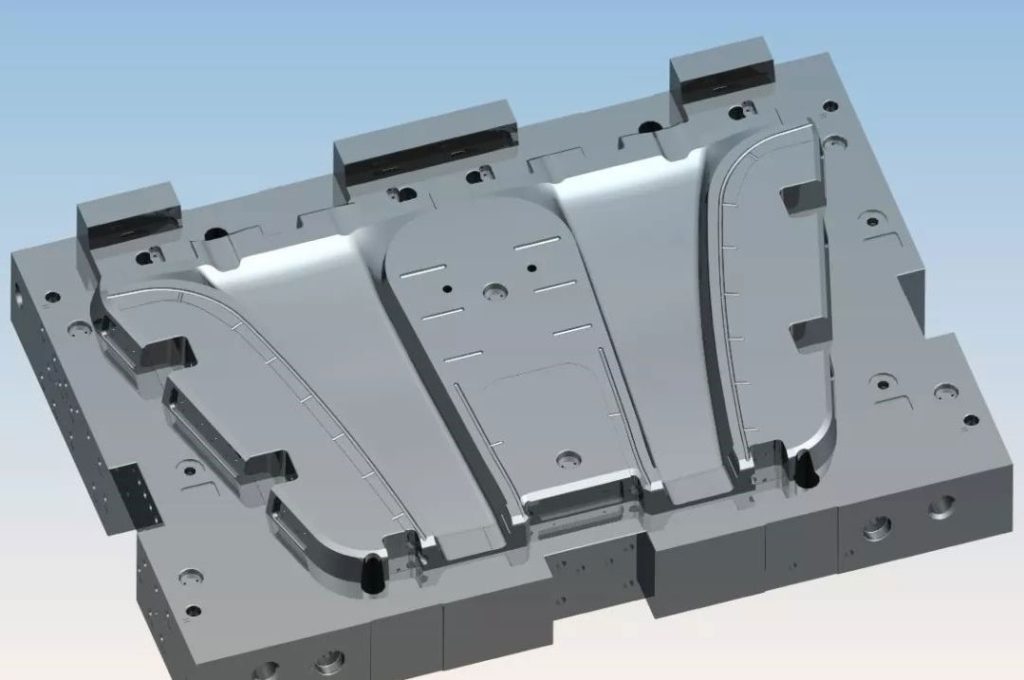

The important factor affecting the service life of the sheet metal lock mold is related to the chemical composition of the material and its strength, toughness, wear resistance, thermal stability, etc. Therefore, it should be according to the actual production needs, reasonably select high-quality steel and implement heat treatment process to improve the service life of the lock sheet metal mold. Then what exactly material is the best choice for a mold?

What Are the Requirements for Material of the Sheet Metal Lock Mold?

- Strength

Strength is a performance indicator that characterizes the deformation resistance and fracture resistance of a material. The design and use of the cold work lock sheet metal mold must ensure that it has sufficient strength to prevent the deformation, cracking and breaking of the lock sheet metal mold. High strength is obtained mainly through the appropriate heat-treatment process.

- Hardness

The hardness of the lock sheet metal mold parts has a great influence on the service life of the lock sheet metal mold, so it is also an important indicator for the design of the lock sheet metal mold.

- Toughness

Toughness is a property of a material to resist cracks under impact load, and it is an important performance index of lock sheet metal die steel. The specific requirements for toughness should be considered according to the working conditions of the lock sheet metal mold. Sufficient toughness is required for lock sheet metal molds with large impact loads, eccentric bending loads or stress concentrations.

- Wear Resistance

In addition to affecting the life of the lock sheet metal mold, wear resistance also affects the dimensional accuracy and surface roughness of the product. Generally, the hardness requirements of sheet metal mold materials for locks should be 30% to 50% higher than the hardness of blanks. The metallographic structure requirements of lock sheet metal mold materials are the lower shells with fine and dispersed fine-grained carbides distributed on the matrix.

- Fatigue Resistance

Fatigue resistance is a performance index that reflects the resistance of materials to fatigue damage under alternating loads. According to different applications, it is divided into fatigue strength, fatigue crack initiation force, fatigue crack propagation resistance, low energy multi-impact resistance, etc.

- Thermal Stability

Thermal stability refers to the ability of the lock sheet metal mold to maintain stable organization and performance due to heat during the use of the lock sheet metal mold. For high-speed blanking or severe friction and wear of cold-worked lock sheet metal molds, some high-alloy steels with secondary hardening ability should be selected.

Among are the requirements for material of sheet metal lock mold, and the following are 6 characters of optional material.

6 Optional Materials for Sheet Metal Lock Mold

- Carbon tool steel

The carbon content of carbon tool steel is in the range of 0.7%~1.3%, the price is cheap, the source of raw materials is convenient, and the processing performance is good. After heat treatment, high hardness and high wear resistance can be obtained. Simple shape, light-loaded lock sheet metal mold parts. T10A is the most commonly used steel. It is a representative carbon tool steel with good performance and high wear resistance. It can obtain high strength and certain toughness after proper heat treatment. Suitable production requires high wear resistance and can withstand impact loads. Smaller lock sheet metal dies. T8A is better than T10A in hardenability and toughness, and has higher wear resistance. It is suitable for making small drawings and extrusion dies.

- Low-alloy tool steel

Low-alloy tool steel is based on carbon tool steel with an appropriate amount of alloying elements added. This can reduce the quenching cooling rate, reduce thermal stress and structural stress, reduce quenching deformation and cracking tendency, and significantly improve the hardenability of steel. The low-alloy steels used in the manufacture of lock sheet metal molds include CrWMn, 9Mn2V, 9SiCr, 9CrWMn, 9Mn27CrSiMnMoV (code CH-1), 6CrNiMnSiMoV (code GD), etc.

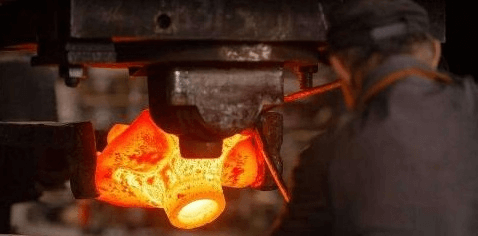

- High carbon and high chromium steel

High carbon and high chromium cold work lock sheet metal die steel includes Cr12, Cr12MoV, and Cr12Mo1V1 (code D2), with high hardness, high strength, high wear resistance, easy to harden and stability. It also has the advantages of high resistance, high compressive strength and small quenching deformation. The forged blank of high carbon and high chromium steel has high hardness (about 550HB) and large internal stress. If it stays at room temperature for a long time, it will crack and be scrapped. In order to eliminate internal stress, reduce hardness and improve cutting performance, it is necessary to carry out annealed.

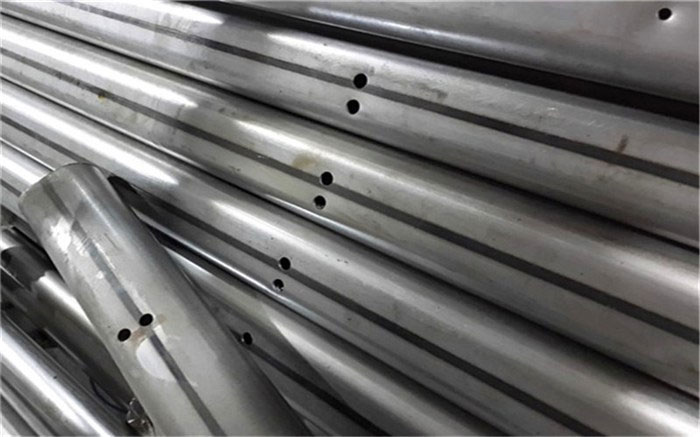

- High-speed steel

Compressive strength and wear resistance, and toughness can be effectively improved by adopting technological measures such as low-temperature quenching and rapid heating. Therefore, high-speed steel is increasingly used in cold-worked lock sheet metal molds that require heavy loads and long life. Tungsten-molybdenum series high-speed steel has relatively high flexural strength, plasticity, impact toughness, etc. due to its relatively uniform distribution of carbides and small particles, and its hardness and secondary hardening ability are maintained.

- Cemented Carbide

It has high hardness, high compressive strength and high wear resistance, so the lock sheet metal mold made of it is strong and durable, and the surface quality of the product is good, so it is suitable for mass production. To make multi-station progressive die, large-diameter deep drawing die inserts. The disadvantage is that it is brittle, difficult to process, cannot be forged and heat-treated, and has high cost, which limits its application.

- Steel-bonded cemented carbide

This is a new type of lock sheet metal mold material produced by powder metallurgy with refractory metal carbide as the hard phase and alloy as the binder. Hardness, high wear resistance and high compressive strength, but also has the machinability and heat treatment of steel.

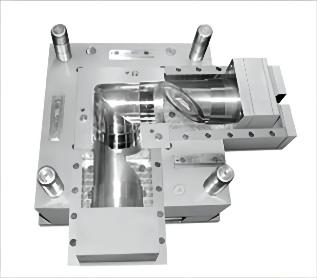

At JTR, there are lots of material options for you to choose from, any products are available to be machined through the sheet metal process, what you only need to do is to provide your CNC 2D/3D design files, and we return you a perfect desired products.