With the development of science and technology, people have put forward various new requirements for the surface performance and appearance of CNC machining of aluminum alloy shells, turning into smoky shades, and shades that are as understated as satin. Thus, electroplating alloys were developed. Here is a brief introduction to several decorative electroplating alloys used in product finishes.

Aluminum alloy shell CNC machining electroplating tin-cobalt alloy

The color tone of electroplated tin-cobalt alloy is similar to that of electroplated cobalt, but it is softer and more popular. At present, most foreign countries are used to replace chromium. Cobalt electroplating is not easy for barrel plating, while electroplating tin-cobalt alloys are suitable for barrel plating of small parts.

In addition, the electroplated tin-cobalt alloy has excellent throwing ability and barrel plating ability, so it can be applied to workpieces with complex shapes. If a double layer of nickel is plated on the bottom layer, its corrosion resistance is no less than that of chrome plating. To prevent discoloration of the surface, it should be treated by impregnation with chromate, which can also improve its corrosion resistance.

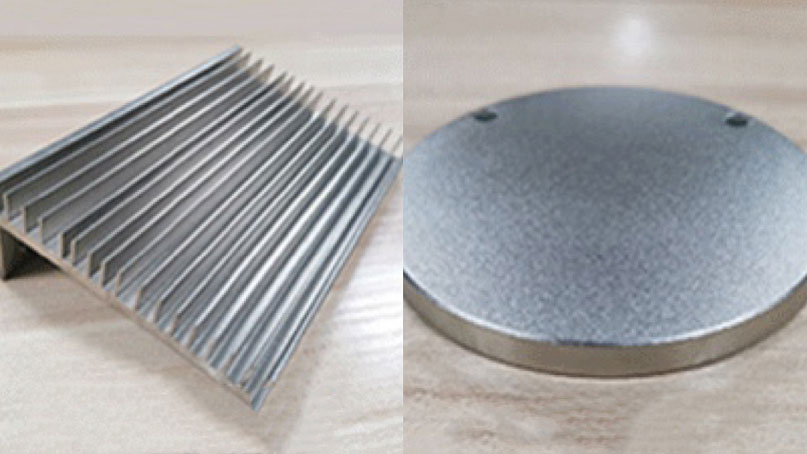

It has a pale rose shade that feels very good and has excellent corrosion resistance. If tin-nickel alloy electroplating is applied to a shiny substrate or a bright nickel electroplating layer, a good glossy surface can be obtained. If electroplating is performed on a matte surface (pear grain), the original condition of the surface can be seen. The throwing ability of the electroplating layer is very excellent, and there is almost no leveling effect, so it is suitable for electroplating extremely fine lines and rotating processed products.

Aluminum alloy CNC machining electroplating copper-tin alloy

The color of the low-tin bronze coating of the aluminum alloy shell is pink or golden, and the crystal is fine. It has a high anti-corrosion ability and good polishing and rotation performance. It is often used as a protective-decorative nickel bottom layer and is used in the light industry and handicraft industry. , the mechanical instrument industry and other industries.

The color of the medium tin bronze coating is golden yellow, and the corrosion resistance is good. Primarily used as a base for decorative chrome plating. The hardness and air stability of aluminum alloy machining are higher than that of low tin bronze coatings. However, due to the high tin content of the coating, the bottom layer of the protective decorative coating is prone to bloom after the chrome coating, which is the weakness of the medium-tin bronze coating.

The high tin bronze coating has beautiful silver-white luster and good polishing and rotation performance, with high hardness and wear resistance. Decorative surface coating.

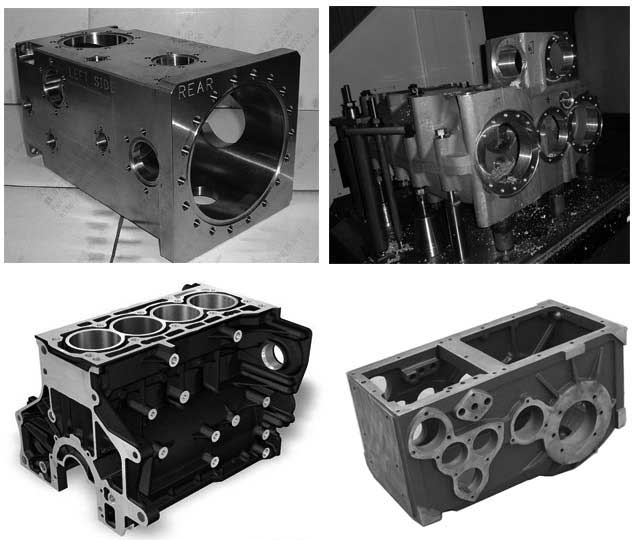

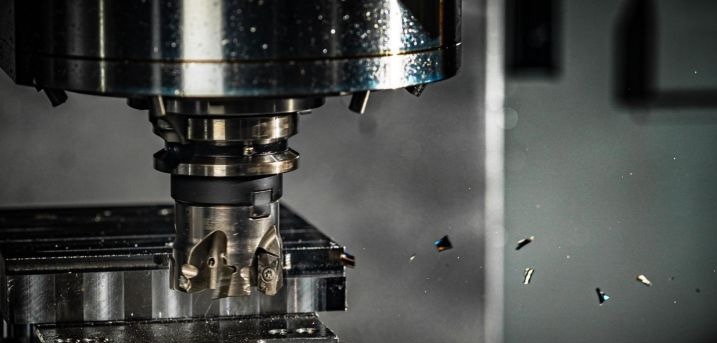

What can JTR do for your aluminum alloy housing CNC machined surface?

JTR is a company specializing in solving CNC machining problems of parts or products for customers. Of course, we are fully capable of surface treatment of the just-formed aluminum alloy shell, which depends on the needs of customers, and our surface treatment methods are not limited to the two mentioned in the article, more surface treatments, please contact us, we will provide you with a plan and a quotation in a short time.