In today’s pursuit of carbon neutrality and electrification, every gram of weight in the automotive industry matters. Lightweighting is no longer an option; it’s a necessity for ensuring range, performance, and market competitiveness. Among all available materials, aluminum alloys stand out as one of the most effective and scalable solutions for reducing vehicle weight without compromising strength or safety.

From chassis structures to engine housings, aluminium casting materials are shaping the next generation of vehicles. The right aluminum alloy for casting can cut weight by up to 40% compared to steel while delivering excellent mechanical and thermal properties.

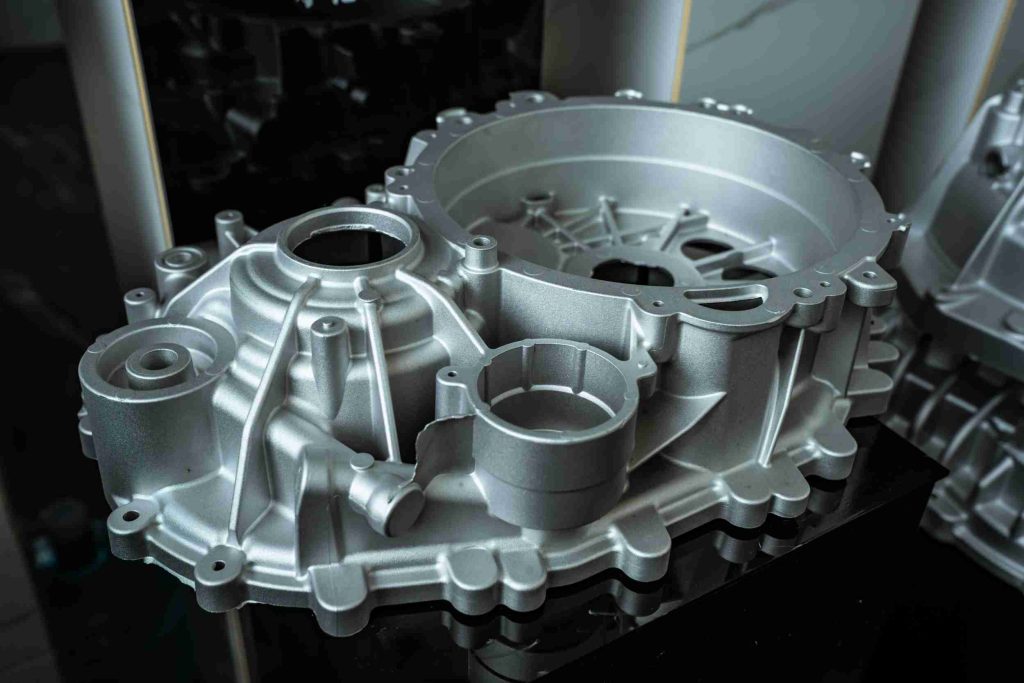

At JTR, we specialize in precision aluminum casting and CNC machining, helping OEMs and suppliers bring advanced aluminium casting materials to life.

The “Invisible” Heroes in Car Body Structures: Where Cast Aluminum Matters Most

The vehicle body is the carrier of the car, and its lightweight demand is urgent. We specialize in producing the following key types of components in this area:

1. Structural & Suspension Parts (e.g., Steering Knuckles, Control Arms)

Primary Alloy: A356 (ZL101A)

Material Characteristics: A356, an Al-Si-Mg series alloy, is renowned for its excellent heat treatability. Through precise T6 heat treatment (solution heat treatment + artificial aging), an optimal balance of strength and toughness (elongation) can be achieved.

For producing such safety-critical parts, we focus on two core control points: First, the purity during melting, employing processes like rotor degassing and filter plates to strictly reduce hydrogen content and inclusions. Second, the precise control of the heat treatment process, ensuring stable and uniform mechanical properties for every batch. Components cast from A356 represent the perfect synergy of lightweighting and safety.

2. Housings and Bracket Parts (e.g., Engine Mounts, Battery Pack Housings, Door Frames)

Primary Alloy: A380 / ADC12

Material Characteristics: These are the most widely used die-casting alloys. They possess excellent castability and fluidity, making them ideal for filling complex thin-walled cavities rapidly. They also offer good mechanical strength, dimensional stability, and resistance to hot tearing.

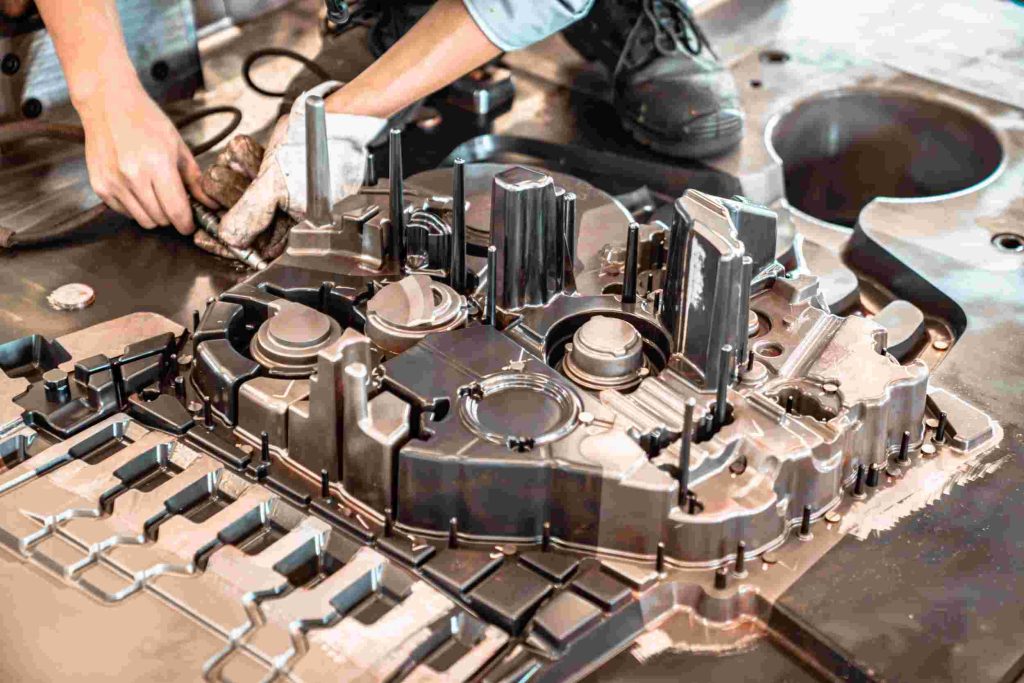

For such large, thin-walled components, we employ High Vacuum Die Casting technology. The high vacuum environment significantly reduces entrapped gas porosity, resulting in a denser casting structure. This allows the castings to be subsequently welded or heat-treated, greatly expanding the application boundaries of die-cast parts. Our engineers utilize mold flow analysis software to optimize the gating and overflow systems, ensuring stable filling and reduced air entrapment, thereby delivering high-quality surface finish and internal structure to our customers.

Comparison of Commonly Used Cast Aluminum Alloys for Body Systems

| Component Type | Recommended Alloy | Core Advantages | Typical Casting Process |

| Structural Parts (Steering Knuckle) | A356 | High Strength, High Toughness, Heat Treatable | Low-Pressure Die Casting, Gravity Die Casting, Squeeze Casting |

| Housings/Brackets | A380 / ADC12 | Excellent Fluidity, High Castability, Cost-Effective | High-Pressure Die Casting (High Vacuum Recommended) |

| High-Strength Beams | A357 / C611 (Ergal) | Ultra-High Strength, Excellent Stress Corrosion Cracking Resistance | Squeeze Casting, Vacuum Die Casting |

The “Efficient” Assistant in Powertrain Systems: Precision Under Heat and Pressure

Whether for Internal Combustion Engines or the E-Drive systems of electric vehicles, this area presents the most demanding requirements for material performance.

1. Engine Components

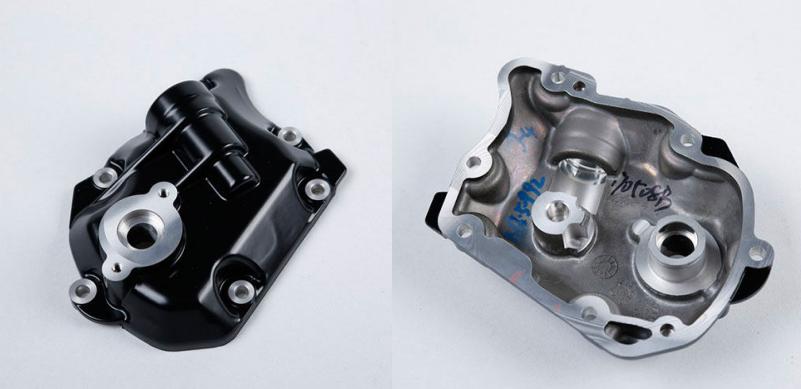

- Cylinder Blocks / Cylinder Heads:

Common Alloys: A356, A319 (Al-Si-Cu)

Blocks and heads feature extremely complex internal structures with intricate water and oil galleries, which can only be realized economically through casting. We employ gravity or low-pressure die casting to ensure microstructural density. For high-performance applications, we strictly control the morphology and distribution of Si particles to enhance wear resistance and high-temperature fatigue performance.

- Pistons:

Common Alloys: Eutectic or Hypereutectic Al-Si alloys (e.g., Al-Si12CuNiMg)

Pistons operate in high-temperature and high-pressure environments, requiring materials with excellent heat resistance, low thermal expansion coefficient, and high wear resistance. By adding elements like Cu, Ni, and Mg to the alloy, we facilitate the formation of stable strengthening phases, ensuring dimensional stability and service life under extreme operating conditions.

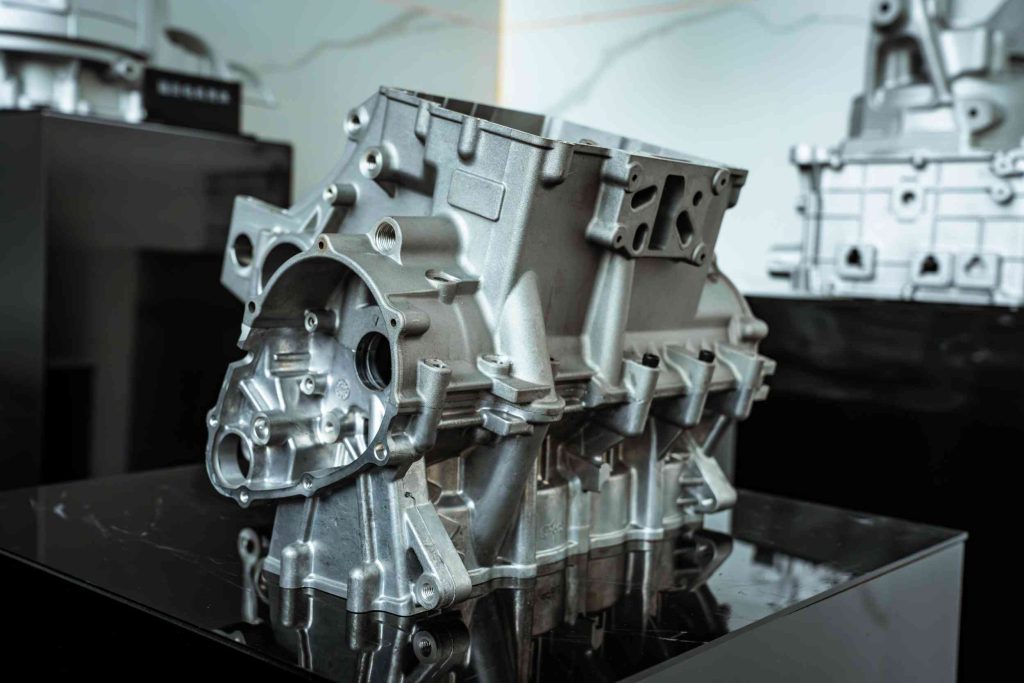

2. E-Drive & Transmission Systems (The Core of the EV Era)

- Motor Housings, Reducer Housings:

Common Alloys: A380, A360 (for superior pressure tightness), ADC12

A motor housing requires not only lightweighting and strength but also exceptional thermal conductivity and pressure tightness. We select A380 or A360, which offers better thermal conductivity, and employ High Vacuum Die Casting to ensure zero leakage in high-pressure oil channels and air paths. Furthermore, we focus on the dimensional stability of the casting after machining, utilizing natural or pre-aging treatments to control the release of internal stresses and prevent deformation during our customers’ machining processes.

Comparison of Commonly Used Cast Aluminum Alloys for Powertrain Systems

| Component Type | Recommended Alloy | Core Advantages | Special Requirements |

| Engine Block | A356, A319 | Good Castability, Balanced Strength & Thermal Conductivity | Internal Soundness, Resistance to Coolant Corrosion |

| Piston | Al-Si12CuNiMg | High Heat Resistance, Low Thermal Expansion, Wear Resistant | High-Temperature Strength, Creep Resistance |

| Motor Housing/Reducer Housing | A380, A360 | Good Fluidity, Thermal Conductivity & Pressure Tightness | High-Vacuum Integrity, Dimensional Stability |

Key Performance Indicators of Cast Aluminum Alloys

Selecting the right cast aluminum alloy is not just a matter of cost — it’s about achieving the right balance between strength, durability, castability, and thermal performance. At JTR Machine, our engineers evaluate every project through measurable material performance indicators, ensuring each component performs reliably under real-world automotive conditions.

Below are the key properties that define the performance of aluminium casting materials in car body and powertrain applications:

1. Mechanical Properties

Mechanical performance determines how a cast aluminum component behaves under static or impact load. The two main parameters are tensile strength and yield strength, which directly affect structural integrity.

| Property | Description | Typical Range (Common Alloys) | Impact on Automotive Design |

| Ultimate Tensile Strength (UTS) | Maximum stress before fracture | 220–320 MPa (A356-T6, A357-T6) | Defines overall load capacity |

| Yield Strength | Stress at onset of plastic deformation | 150–275 MPa | Determines stiffness and dimensional stability |

| Elongation at Break | Ductility or stretch before failure | 3–10% depending on alloy & heat treatment | Higher values improve crashworthiness |

| Hardness (HB) | Surface resistance to wear or indentation | 70–100 HB | Critical for friction surfaces and joints |

JTR uses finite element analysis (FEA) and mechanical testing to validate that each cast component meets its design load and fatigue criteria.

2. Fatigue Performance

Automotive components such as engine housings, control arms, and wheel hubs experience cyclic loading during operation. Even small fluctuations in stress can lead to fatigue failure if the alloy microstructure is not optimized.

Key Factors Affecting Fatigue Life:

- Microstructure uniformity – minimized porosity and refined grain size improve fatigue strength.

- Heat treatment (T5/T6) – precipitation hardening increases fatigue endurance limit.

- Alloy system – Al-Si-Mg alloys like A357 offer superior fatigue life compared to Al-Si-Cu systems.

Some common alloys including:

| Alloy | Fatigue Strength (MPa) | Recommended Application |

| A356-T6 | 90–110 | Structural brackets, knuckles |

| A357-T6 | 100–130 | Suspension arms, cross members |

| AlSi9Cu3 | 80–95 | Powertrain housings, EV motor cases |

At JTR, we apply high-pressure vacuum die casting and controlled cooling techniques to minimize porosity and enhance fatigue reliability – a key differentiator in high-performance automotive parts.

3. Castability: Fluidity, Shrinkage, and Defect Control

Castability defines how well a molten alloy fills a mold and solidifies without defects such as porosity, cold shuts, or shrinkage cavities.

High cast aluminum grades like A380 and ADC12 are favored for complex thin-wall parts due to their excellent fluidity and low solidification shrinkage.

| Property | Description | Advantage |

| Fluidity | Ability to fill thin sections during casting | Ensures complex part geometry and consistent wall thickness |

| Shrinkage Control | Resistance to internal voids and cavities | Reduces rework, improves dimensional accuracy |

| Hot Tearing Resistance | Alloy’s ability to resist cracking during solidification | Enhances mold release and yield rates |

At JTR , mold flow simulation is used during design to predict and control metal flow, ensuring the best cast aluminum material properties are achieved across every batch.

4. Thermal and Electrical Conductivity

As electric vehicles (EVs) rise, thermal management becomes a top design challenge. Aluminum alloys offer excellent heat transfer and electrical conductivity, crucial for motor housings, inverter casings, and battery trays.

| Property | Typical Range | Function |

| Thermal Conductivity | 120–160 W/m·K (A380, AlSi9Cu3) | Efficient heat dissipation in engines and EV motors |

| Electrical Conductivity | 35–45% IACS | Improves current flow and energy efficiency |

| Coefficient of Thermal Expansion (CTE) | ~22 × 10⁻⁶ /°C | Maintains dimensional stability across temperature cycles |

By adjusting alloy composition and heat treatment, JTR helps clients fine-tune thermal properties to improve energy efficiency and part longevity.

5. Heat Treatability and Microstructural Control

One of the greatest strengths of cast aluminum alloys lies in their ability to be heat-treated for enhanced performance.

- T5 Treatment: Artificial aging after casting — improves hardness and dimensional stability.

- T6 Treatment: Solution heat treatment followed by aging — significantly increases tensile and yield strength.

- T7 Treatment: Stabilizing treatment — improves thermal resistance for high-temperature environments (e.g., engine blocks).

Microstructure refinement through magnesium and silicon control, combined with optimized cooling rates, enables JTR to deliver consistent mechanical and fatigue performance across large-volume production runs.

6. Corrosion Resistance and Surface Quality

Automotive components often face harsh environments — moisture, salts, and temperature fluctuations. Corrosion resistance is therefore a critical performance metric.

- Al-Si-Mg alloys (A356, A357) show excellent corrosion resistance and can be anodized or powder-coated.

- Al-Si-Cu alloys (A380, ADC12) may require surface finishing (e.g., e-coating or painting) to protect against oxidation.

JTR offers post-casting treatments such as anodizing, passivation, and coating, ensuring both long-term durability and visual quality for customer-facing components.

Performance Shapes Material Choice

| Key Property | Best Performing Alloys | Typical Applications |

| Strength & Ductility | A356, A357 | Suspension, structural parts |

| Fatigue Resistance | A357, AlSi9Cu3 | Powertrain, EV housings |

| Castability | A380, ADC12 | Complex thin-wall die castings |

| Thermal Conductivity | AlSi9Cu3, A380 | Motor housings, cooling systems |

| Corrosion Resistance | A356, A357 | Exterior and exposed components |

What JTR Machine Can Do for You

As a trusted aluminum casting manufacturer in China, JTR Machine combines foundry expertise, CNC precision machining, and flexible production capacity to help automotive clients accelerate product development and ensure consistent part quality.

Our Capabilities Include:

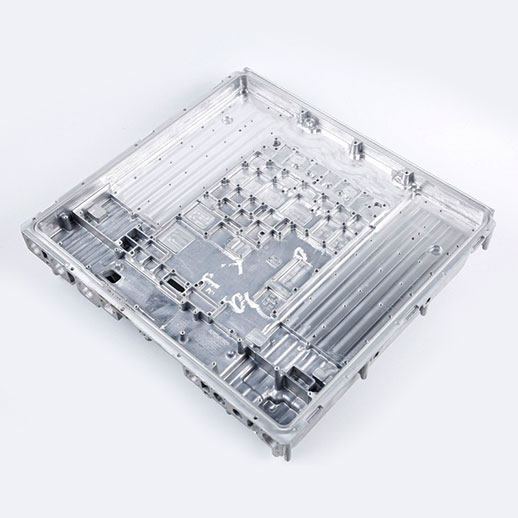

- High-pressure aluminum die casting (50T–2000T)

- Precision CNC machining and finishing

- Rapid prototyping and small-batch casting

- Custom mold design and tooling optimization

- ISO/IATF certified quality management

Whether you need a lightweight suspension bracket, a precision gearbox housing, or a custom EV motor casing, JTR delivers end-to-end manufacturing solutions that meet the performance and cost demands of modern automotive engineering.

As the automotive industry moves toward electrification and lightweight design, cast aluminum alloys will continue to play a defining role in balancing performance, cost, and sustainability. With our integrated casting and machining capabilities, we help automakers worldwide turn material innovation into mechanical excellence.