If you just want the fastest answer: Tin is the easiest metal to cast.

It melts at only 232 °C (450 °F), which means you can pour it using a small electric furnace or even a propane torch. Tin is also non-toxic, flows smoothly into molds, and requires almost no special equipment—making it perfect for beginners, hobbyists, and small art projects.

But “easy” can mean different things depending on your goal—cost, safety, CNC machining potential, or artistic detail. Let’s look at the most common casting metals and see which one fits your needs best.

| Metal | Melting Point °C | Casting Ease | Cost | Safety | DIY Friendly | CNC Machining Potential |

| Tin | ~232 | ⭐⭐⭐⭐⭐ (lowest temp) | Low | Very safe | Excellent | Fair |

| Aluminum | ~660 | ⭐⭐⭐⭐ | Low | Safe | Good | ⭐⭐⭐⭐⭐ |

| Zinc | ~420 | ⭐⭐⭐⭐ | Low | Safe | Good | ⭐⭐⭐⭐ |

| Lead | ~327 | ⭐⭐⭐⭐ | Very low | Toxic fumes | Not recommended | Fair |

| Brass/Bronze | ~900 | ⭐⭐ | Moderate | Safe with care | Medium | ⭐⭐⭐⭐ |

| Copper | ~1,085 | ⭐⭐ | Higher | Safe with care | Hard | ⭐⭐⭐⭐⭐ |

| Silver | ~961 | ⭐⭐ | Expensive | Safe with care | Hobby/jewelry | ⭐⭐⭐⭐ |

| Gold | ~1,064 | ⭐⭐ | Very expensive | Safe with care | Jewelry only | ⭐⭐⭐⭐ |

| Steel/Iron | >1,370 | ⭐ | High | Requires industrial furnace | Very hard | ⭐⭐⭐⭐⭐ |

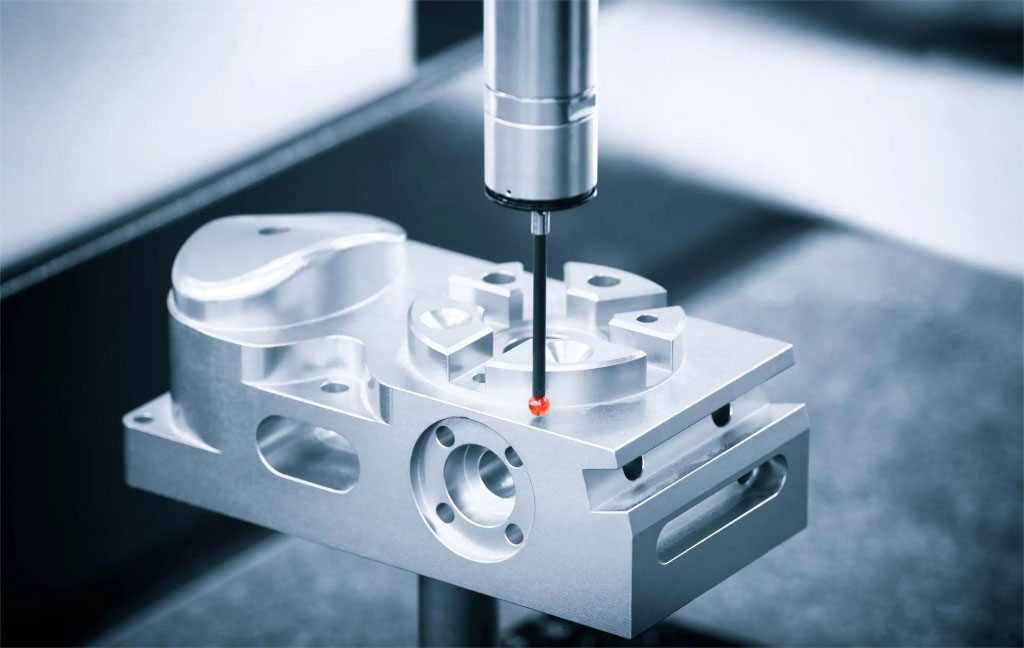

So, What Is the Easiest Metal to Cast for CNC Machining?

If your goal is to make cast parts that are easy to machine—not just to melt and pour—

the easiest and most practical answer is Aluminum.

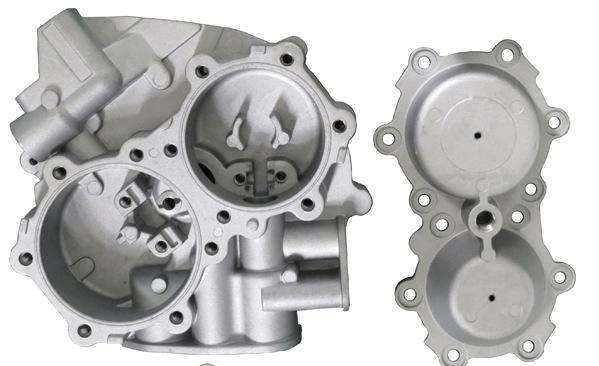

Aluminum alloys combine excellent castability (they flow well into molds, fill details, and cool with minimal cracking) with outstanding CNC machinability.

This means you can pour a near-net shape part and then quickly mill, drill, or turn it to final dimensions with minimal tool wear.

Why Aluminum Stands Out

| Property | Why It Matters for Casting + CNC |

| Good Fluidity | Fills complex molds without excessive pressure or vacuum. |

| Low Shrinkage | Less distortion → less machining stock needed. |

| Soft but Strong | Cuts cleanly without destroying tools. |

| Lightweight | Easy handling, cheaper shipping. |

| Wide Alloy Range | A356, 6061, 7075 etc. allow balancing strength and machinability. |

| Surface Finish | Machines to a smooth finish, easy anodizing. |

For small shops, hobbyists, and CNC service providers, aluminum is almost always the lowest total cost from casting to finished part.

Other Metals Worth Considering

| Metal | Castability | CNC Machinability | Cost | Typical Use |

| Brass/Bronze | Excellent | ⭐⭐⭐⭐⭐ (but slightly harder than Al) | Moderate | Valve bodies, decorative hardware |

| Zinc Alloys (e.g. Zamak) | Excellent (pressure die-casting) | ⭐⭐⭐⭐ | Low | Small complex parts, consumer products |

| Magnesium | Good | ⭐⭐⭐⭐ | Moderate | Lightweight automotive/aerospace |

| Copper | Fair | ⭐⭐⭐⭐ (needs sharp tools) | Higher | Electrical components |

| Steel/Iron | Fair (needs high temp) | ⭐⭐⭐ | Moderate/High | Heavy-duty machine parts |

| Titanium | Poor (difficult to cast) | ⭐ | Very High | Aerospace only |

- Brass: nearly as easy to machine as aluminum, better wear resistance, but heavier and more expensive.

- Zinc alloys: exceptional for thin, complex shapes (like door handles), but softer and weaker.

- Magnesium: machines beautifully but requires special safety handling (flammable chips).

- Steel/Iron: great strength, but slow machining and high tool wear.

Best by CNC Service Type

| Service | Recommended Metal | Reason |

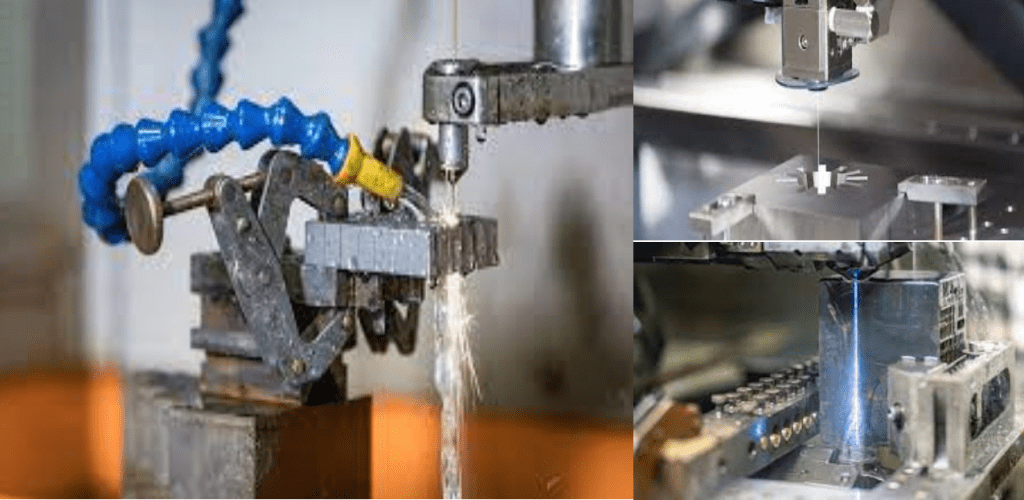

| CNC Machining (general) | Aluminum | Fast cutting, low tool wear, excellent surface finish. |

| CNC Milling | Aluminum / Brass | Both hold tight tolerances and allow fine details. |

| CNC Turning | Brass / Aluminum / Steel (pro) | Brass for smooth chips, aluminum for speed, steel for strength. |

Final

If your main priority is casting a part that can be easily CNC machined into a precision component,

- For a balance of castability, machining ease, and cost : Aluminum.

- For the best surface finish and tool life: Brass.

- For small, complex shapes at low cost: Zinc alloys.