When I first stepped into the world of metal casting, I kept hearing the term “Five-Five process.” It sounded technical, but the idea is actually simple: it’s just a way to group the five main casting methods most manufacturers rely on today.

All casting processes can be divided into two broad categories:

- Traditional Sand Casting (the most widely used)

- Special Casting

- Using natural minerals and sand as mold material (such as investment casting, clay casting, shell molding, vacuum casting, full mold casting, ceramic mold casting, etc.)

- Using metal as the primary mold material (such as permanent mold casting, die casting, continuous casting, low-pressure casting, centrifugal casting, etc.)

What Are the Five-Five Metal Casting Processes?

Here’s how the “Five-Five” breaks down:

| Category | Process (The “Five-Five”) | What It’s Best Known For |

| Traditional Casting | Sand Casting | Affordable, flexible, works for large and small batches |

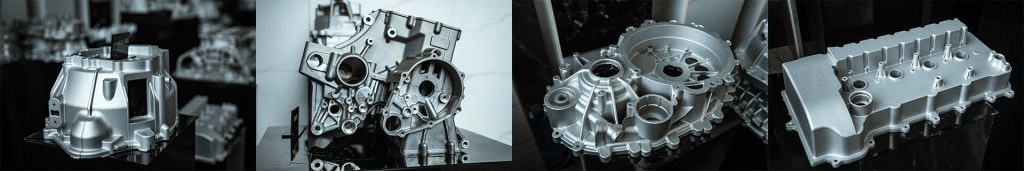

| Special Casting | Die Casting | High precision, smooth finish, great for aluminum & zinc |

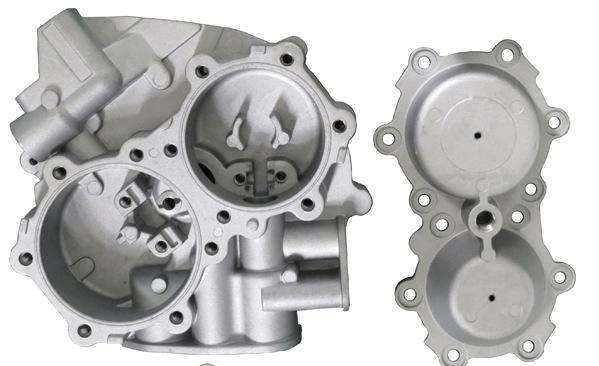

| Low Pressure Casting | Stronger parts, fewer defects, good for wheels & alloys | |

| Centrifugal Casting | Perfect for round/tubular shapes like pipes and bushings | |

| Investment Casting | Low-Pressure Casting |

So, what’s the difference between them? And more importantly: which one fits your budget, timeline, and quality needs? Let’s break it down in plain English.

Sand Casting – Low Cost, Large Parts (Best for Iron, Steel, Aluminum & Copper Alloys)

If I had to sum up sand casting in one word, it would be “versatile.” It’s the most common method: sand is packed around a pattern, molten metal is poured in, then the mold is broken away once it cools.

Comparison Table of Metal Casting Processes

| Process | Best Materials | Accuracy / Finish | Cost Level | Best Use Cases | Watch Out For |

| Sand Casting | Iron, steel, alloys | Low / rough | Low | Large, cost-sensitive parts | Rough finish, less accurate |

| Die Casting | Aluminum, zinc, mag. | Low-Pressure Cast. | High (mold) | Thin-walled, mass production | High mold costs |

| Low Pressure Cast. | Aluminum, magnesium | Med-High | Medium | Wheels, structural parts | Slower cycles |

| Centrifugal Cast. | Iron, steel, bronze | High (round only) | Medium | Pipes, bushings, rings | Only round shapes |

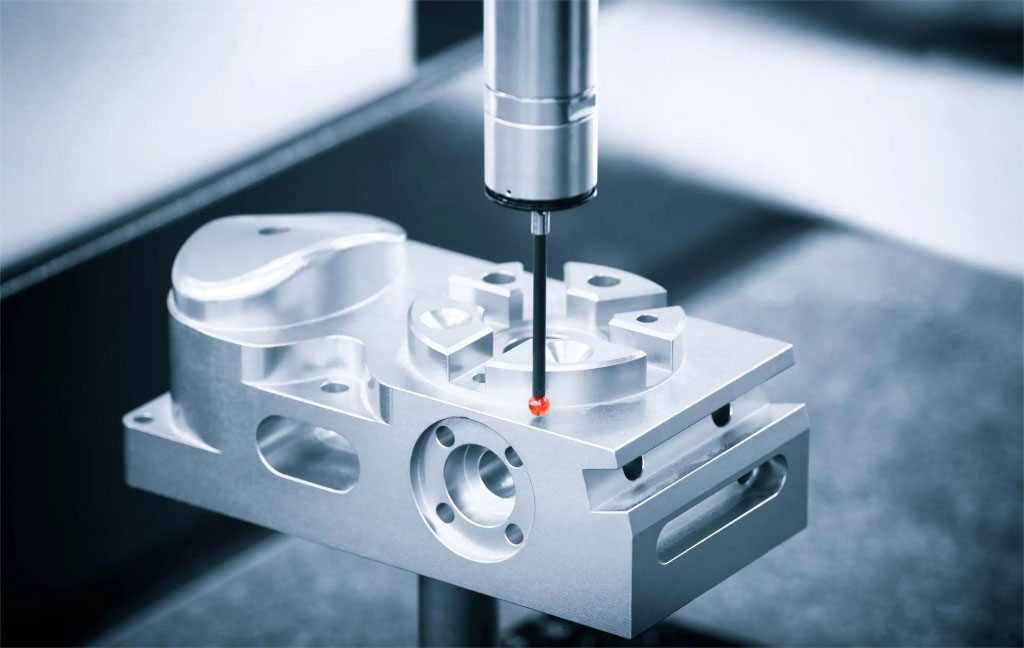

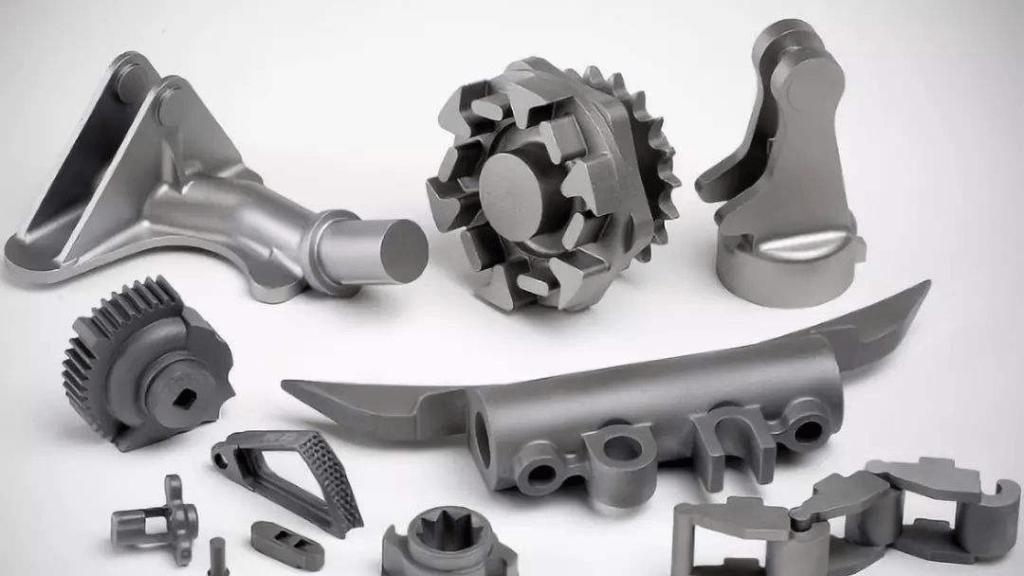

| Investment Cast. | Stainless, titanium | Very High | High | Complex, high-value parts | Cost + long lead times |

How to Choose the Right Metal Casting Process

| Decision Factor | Condition / Question | Recommended Process | Why It Fits Best |

| Budget | Tight | Sand Casting | Low cost, flexible |

| Generous | Investment / Die Casting | High precision, smooth finish | |

| Batch Size | Large volume | Die Casting | High speed, repeatability |

| Small runs | Sand / Investment Casting | Cost-efficient for low volume | |

| Part Complexity | Simple shapes | Sand / Centrifugal Casting | Lower cost, easier tooling |

| Complex, detailed | Investment Casting | Excellent detail & finish | |

| Material | Aluminum / Zinc | Die / Low Pressure Casting | Thin walls, precision |

| Steel / Stainless Steel | Sand / Investment Casting | Handles high melting points | |

| Shape | Round / Hollow | Centrifugal Casting | Dense, strong tubular parts |

| Thin-walled | Die Casting | Smooth, accurate, thin walls |

Final: Which Casting Process Is Best

At first glance, the casting world might feel overwhelming. But once you understand the five core processes, it becomes much easier to choose the right fit. Whether you’re a buyer sourcing parts or a manufacturer planning production, knowing these options can save you money, reduce headaches, and deliver better results.

In the end, there’s no universal “best” method — only the one that matches your part size, shape, material, and budget. And if you’re unsure? My advice is simple: talk to your supplier. With the right details, they’ll guide you to the process that makes the most sense for your project.