Sandblasting is one of the most effective surface treatment methods in modern metal fabrication. Whether it’s for cleaning, texturing, or preparing parts for coating, the outcome of sandblasting depends heavily on the metal material itself. From steel and aluminum to copper, titanium, magnesium, and cast iron, each reacts differently to abrasives, air pressure, and blasting media.

Here at JTR, we will compare six common industrial metals, detailing the optimal blast strategy for each. Whether you are prepping for powder coating or seeking a specific matte finish, understanding these nuances is essential for quality control and cost efficiency.

Comparative Analysis of Six Metals

| Metal Type | Surface Hardness | Typical Blast Media | Main Purpose of Sandblasting | Notes from JTR‘s Manufacturing Experience |

| Carbon Steel / Stainless Steel | High | Aluminum oxide, steel grit | Rust removal, coating prep, surface roughening | Strong and durable, ideal for high-pressure blasting. Stainless steel requires care to avoid embedding contaminants. |

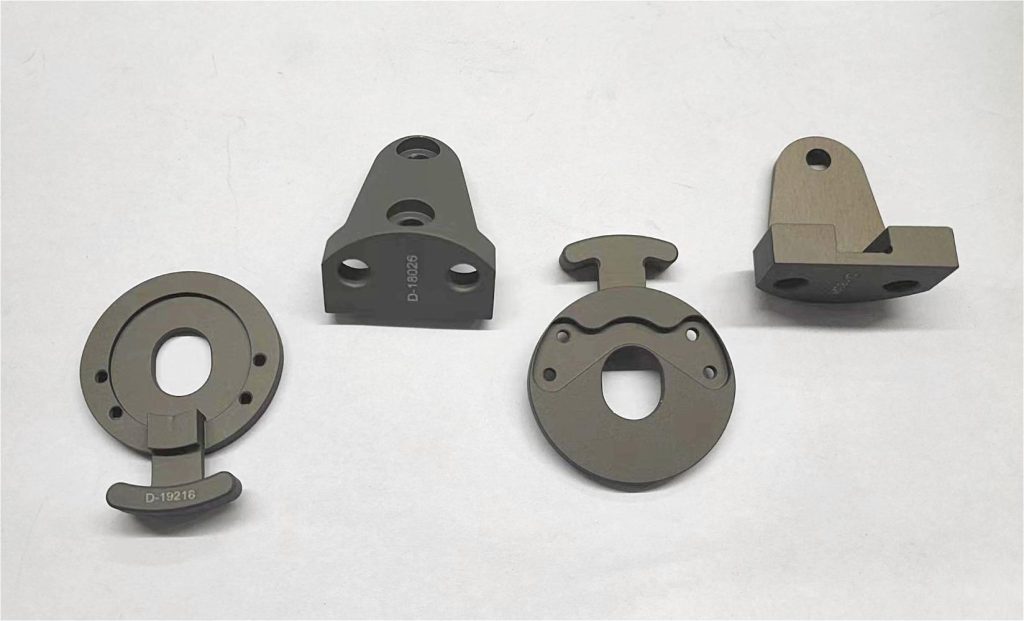

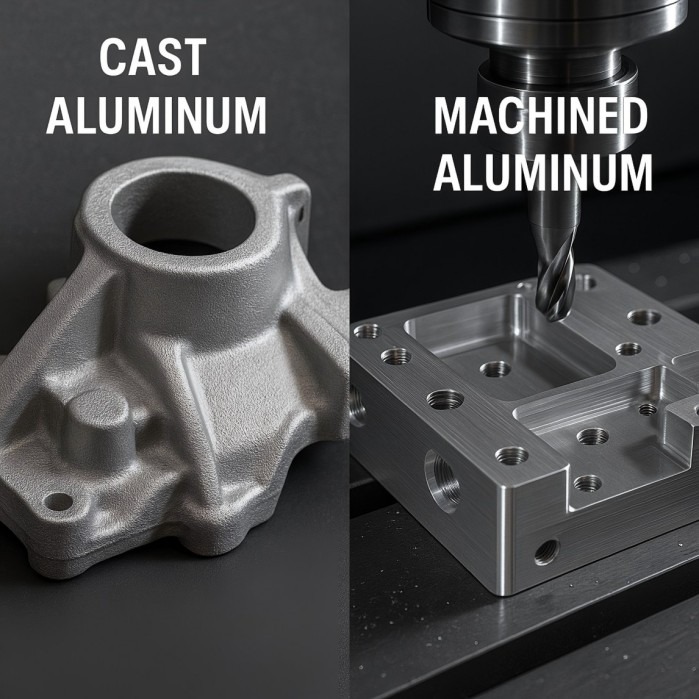

| Aluminum & Aluminum Alloys | Low–Medium | Glass beads, plastic media | Surface finishing, deburring, matte texture | Softer metal—low-pressure, fine abrasives preferred to prevent warping or over-etching. |

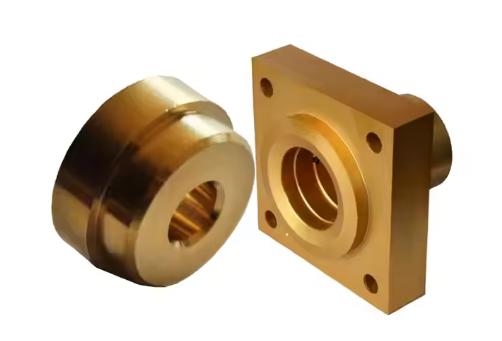

| Copper / Brass | Medium | Glass beads, fine garnet | Surface cleaning, decorative finishing | Susceptible to discoloration; gentle media ensure aesthetic preservation. |

| Titanium | High | Aluminum oxide, silicon carbide | Oxide removal, coating prep | Hard and corrosion-resistant; precise control needed to maintain tight tolerances. |

| Magnesium Alloys | Low | Glass beads, walnut shell | Cleaning and surface activation | Extremely light and soft—best treated with non-aggressive media to avoid erosion. |

| Cast Iron | Very High | Steel grit, aluminum oxide | Rust scale removal, texture enhancement | Rough and porous surface absorbs energy well; effective for industrial and machinery components. |

Key Comparison Dimensions

1. Surface Hardness and Blast Media Selection

The first rule of effective sandblasting: match the media to the metal hardness.

- Hard metals like steel and cast iron handle aggressive abrasives, achieving fast cleaning and strong adhesion for coatings.

- Soft metals such as aluminum and magnesium require gentler materials (like glass beads or walnut shells) to avoid surface damage.

At JTR, aluminum alloy parts are often blasted using low-pressure glass beads, creating a uniform satin finish ideal for anodizing or powder coating.

2. Oxidation Behavior and Surface Reactivity

Each metal’s oxidation rate changes how it should be blasted:

- Aluminum quickly forms a natural oxide layer—sandblasting helps refresh the surface before coating.

- Copper and brass can tarnish after exposure; controlled, low-impact blasting keeps their metallic luster intact.

- Titanium, though oxidation-resistant, often requires blasting to remove weld discoloration or prep for medical or aerospace coatings.

3. Surface Finish and Functional Purpose

Not all sandblasting aims for the same goal:

- Aesthetic Finishing: Aluminum and brass benefit from fine, decorative texturing.

- Mechanical Cleaning: Steel and cast iron need deeper surface removal to eliminate rust or mill scale.

- Precision Preparation: Titanium and magnesium parts—especially for aerospace and automotive—require micro-controlled blasting for consistent coating adhesion.

4. Cost and Processing Efficiency

| Metal | Typical Blasting Time | Cost Sensitivity | Efficiency Optimization Tips |

| Carbon / Stainless Steel | Fast | Low | Use high-pressure, recyclable media. |

| Aluminum Alloys | Medium | Medium | Reduce pressure, use fine media, recycle carefully. |

| Copper / Brass | Slow | High | Gentle media, minimal handling. |

| Titanium | Slow | High | Precision-controlled nozzles to prevent microdamage. |

| Magnesium | Medium | High | Avoid heat buildup—short, cool blasts. |

| Cast Iron | Fast | Low | Aggressive blasting maximizes throughput. |

Common Challenges & Solutions

| Challenge | Metal Type Affected | JTR Recommended Solution |

| Over-blasting (surface pitting) | Aluminum, Magnesium | Use low-pressure, soft abrasives. Maintain constant nozzle distance. |

| Contaminant embedding | Stainless Steel, Titanium | Use non-ferrous blasting media to avoid surface contamination. |

| Uneven matte finish | Copper, Brass | Calibrate media size and flow rate for uniformity. |

| Surface warping | Thin Aluminum Panels | Reduce air pressure and adopt short-cycle blasting. |

| Media clogging or inconsistent flow | Cast Iron | Regularly clean blasting system and use dry air. |

Which Metal Suits Which Application?

| Application Scenario | Recommended Metal | Reason |

| Automotive & machinery components | Carbon Steel / Cast Iron | Durable, easy to clean, suitable for heavy-duty coatings. |

| Consumer electronics housing | Aluminum Alloys | Lightweight, aesthetic finish, easy to anodize. |

| Decorative or conductive parts | Copper / Brass | Excellent visual appeal and conductivity. |

| Aerospace & medical devices | Titanium | High strength-to-weight ratio, corrosion-resistant surface. |

| Lightweight frames & casings | Magnesium Alloys | Ultra-light, ideal for mobility-focused designs. |

Conclusion: The Right Blast for the Right Metal

From rugged steel gears to sleek aluminum enclosures, sandblasting is far from a one-size-fits-all process. The right combination of media, pressure, and technique can define not only the look but also the performance of the final part.

At JTR, we specialize in precision machining and surface finishing for diverse metals—including CNC machining, sandblasting, and anodizing services for aluminum alloys. With years of experience serving industries from automotive to aerospace, we know that understanding the material is the first step toward mastering the finish.

Explore JTR’s full metal processing capabilities from here.