Every engineer working on precision parts has encountered a similar question. Which is more accurate – CNC machining or 3D printing? The answer does seem straightforward. Machine centers would achieve a precision of 0.025mm compared to 3D printing’s 0.1mm accuracy. But in practice, Machine centers would achieve a precision of 0.025mm compared to 3D printing’s 0.1mm accuracy. But does 0.1mm really make a difference in how a part looks, fits, or functions?

Also, does it make sense to narrow the CNC machining and 3D printing to simply accuracy?

This is to provide a more confident answer regarding technology selection for a particular project, this assignment looks at both CNC and 3D printing. The assignment not only requires Accuracy, but also precision, consistency, and the trade-offs of each particular technology as well.

CNC vs. 3D Printing: Comparing the Numbers

There are some basic processes that need to be understood in order to grasp the essence of precision.

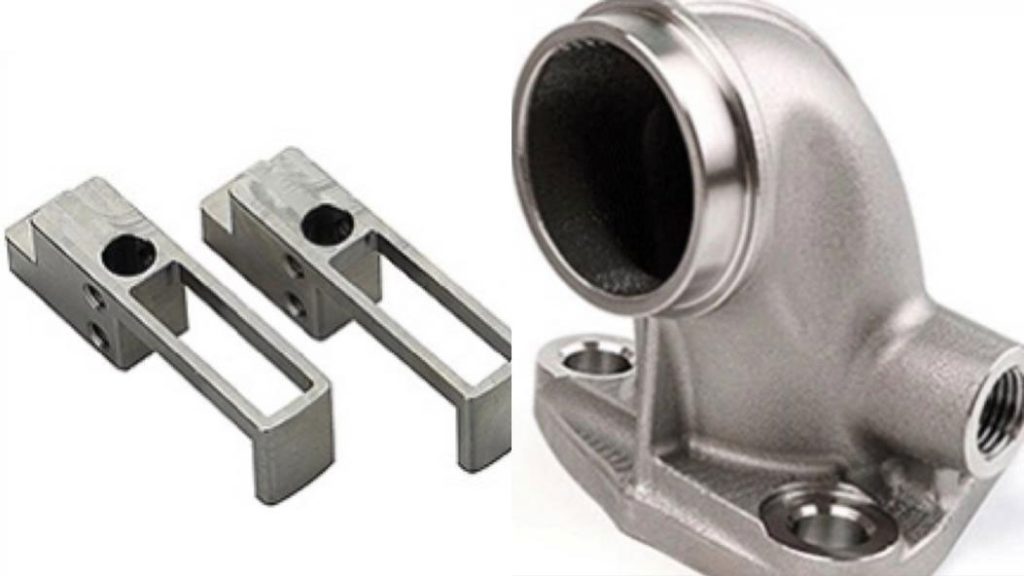

CNC machining processes are subtractive, using various cutting tools to remove material, and 3D printing processes are additive in that they construct a part a layer at a time.

Both methods define significantly different tolerances that can be achieved.

| Technology | Typical Accuracy | Common Tolerance Range | Surface Roughness (Ra) |

| CNC Machining | ±0.025 mm (standard) to ±0.005 mm (high-end) | ±0.01–0.05 mm | 0.8–3.2 μm |

| 3D Printing (FDM) | ±0.2 mm or ±0.002 mm/mm | ±0.1–0.3 mm | 6.3–25 μm |

| 3D Printing (SLA/SLS) | ±0.1 mm or ±0.0015 mm/mm | ±0.05–0.15 mm | 1.5–10 μm |

CNC machining offers 4–10× higher precision and significantly smoother surface finishes, while 3D printing delivers unmatched design freedom and faster iteration.

How does CNC compare to 3D printing in terms of accuracy?

| Aspect | CNC Machining | 3D Printing |

| Principle | CNC (Computer Numerical Control) removes material from a solid block using precisely controlled cutting tools. Its mechanical rigidity and motion control deliver exceptional dimensional accuracy. | An additive process that builds parts layer by layer. Precision depends on layer height, printing orientation, thermal stability, and calibration. |

| Materials | Metals (aluminum, steel, titanium) and engineering plastics (POM, PEEK, nylon). Mechanical properties are stable and isotropic. | Plastics, resins, nylons, and metal powders. Mechanical strength varies with orientation — parts are often anisotropic. |

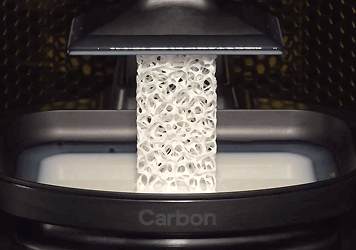

| Geometric Complexity | Limited by tool access; undercuts or internal channels may require multi-axis setups or assembly. | Exceptional. Enables internal channels, lattice structures, and organic geometries impossible for CNC. |

| Cost | Higher per part due to setup, tooling, and machining time — but more economical for medium or large batches. | Support removal, sanding, curing, polishing, or coating is often required for functional or aesthetic quality. |

| Post-Processing | Often minimal. Surfaces can be polished, anodized, or plated for protection and aesthetics. | Support removal, sanding, curing, polishing, or coating often required for functional or aesthetic quality. |

| Tolerances | Typically ±0.01–0.05 mm; precision machines can reach ±0.005 mm. | FDM: ±0.1–0.3 mm; SLA/SLS: ±0.05–0.15 mm. |

| Surface Finish | Ra 0.8–3.2 μm — smooth enough for direct assembly. | Moderate (SLA/SLS) to rough (FDM); visible layer lines are typical. |

| Isotropy | Excellent; mechanical properties are consistent in all directions. | Limited; vertical (Z) direction often weaker due to layer bonding. |

| Repeatability | Extremely high. Even across 100 parts, variation stays within ±0.01 mm. | Moderate; batch variations of ±0.05–0.1 mm depending on temperature, calibration, and material lot. |

±0.025 mm vs. ±0.1 mm: What Do These Accuracy Numbers Actually Mean in Real Life?

It’s easy to read ±0.025 mm vs. ±0.1 mm — but hard to grasp the impact.

Here’s what those numbers mean in practical terms:

| Application | Precision Sensitivity | Real-World Impact |

| Gear housings, bearing fits | Very high | ±0.1 mm may cause interference or misalignment |

| Plastic enclosures, casings | Medium | ±0.1 mm variation is visually acceptable |

| Prototype validation | Low | ±0.2 mm still suitable for design checks |

| Display or demo models | Very low | Tolerance differences are negligible |

- ±0.025 mm ≈ , one-third the thickness of a human hair.

- ±0.1 mm ≈ is the gap between smartphone panels.

- CNC machining delivers a mechanical-level fit,

- while 3D printing provides visual-level accuracy.

Is Accuracy the Only Factor That Matters?

No. In real manufacturing, precision is just a slice of the pie.

Material characteristics, pricing, design mobility, and time for delivery bring just as much value, if not more.

| Factor | CNC Machining | 3D Printing |

| Material Strength | High, isotropic | Varies, often anisotropic |

| Design Freedom | Limited by tool geometry | Extremely high, supports complex shapes |

| Cost per Part | Higher setup, lower at scale | Lower setup, higher per-unit for batches |

| Lead Time | Longer (setup/programming) | Shorter (direct from CAD) |

| Repeatability | Excellent | Moderate |

| Best for | Functional or load-bearing parts | Rapid prototyping, complex geometry |

- CNC = precision + stability,

- 3D printing = flexibility + speed.

How Is Precision Achieved — and How Consistent Is It?

| Technology | How Precision Is Achieved | Consistency Level |

| CNC | Through rigid machine frames, precision tooling, thermal compensation, and feedback control. | Very high — variation within ±0.01 mm even across 100 parts. |

| 3D Printing | Through layer thickness, print orientation, and temperature control. | Moderate — variation within ±0.05–0.1 mm depending on conditions. |

- The accuracy of a CNC machine’s cutting is always mechanical and deterministic; there is always a measurement and compensation for each cut.

- The accuracy of a 3D printer is thermal and probabilistic. It is dependent on shrinkage, printer orientation, and the environment.

What Trade-Offs Are Required to Reach High Precision?

Achieving high accuracy always costs something — time, money, or process flexibility.

| Trade-Off Factor | CNC Machining | 3D Printing |

| Machining/Build Time | Long (complex toolpaths) | Short (automated layers) |

| Material Efficiency | Low (subtractive waste) | High (additive efficiency) |

| Setup Cost | High (fixtures, tooling) | Low |

| Post-Processing | Optional (polishing, plating) | Often mandatory (sanding, curing) |

| Labor Skill | Skilled operator required | Mostly automated |

| Consistency | Excellent | Moderate |

“CNC provides you with precision mastery through control and time; 3D printing offers you speed, simplicity, and freedom.”

CNC vs. 3D Printing: Which Technology Should You Choose for Your Project?

| Project Requirement | Recommended Process | Reason |

| High-precision assemblies (shafts, molds) | CNC | ±0.01 mm tolerance, perfect for functional fits |

| Rapid prototyping and design validation | 3D Printing | Fast turnaround, low cost |

| Complex or lightweight structures | 3D Printing (SLS/SLM) | Enables topology-optimized geometries |

| Small-batch production | CNC | Reliable, consistent results |

| Aesthetic models or visual mock-ups | SLA 3D Printing | Smooth surface and fine detail |

- Use 3D printing for design iteration

- CNC for final precision manufacturing.

Conclusion

CNC vs. 3D Printing: Who Wins in Accuracy?

| Comparison Aspect | Winner | Explanation |

| Dimensional Accuracy | CNC | ±0.005–0.025 mm achievable |

| Surface Finish | CNC | Smooth, assembly-ready surfaces |

| Geometric Freedom | 3D Printing | Internal channels, lattice structures |

| Production Speed | 3D Printing | Fast, no tooling required |

| Repeatability | CNC | Consistent across batches |

| Cost Flexibility | 3D Printing | Ideal for low-volume runs |

- The surface finish, repetition, and precision of CNC machining are unrivalled.

- In terms of speed, design freedom, and cost efficiency, CNC machining is outperformed by 3D printing.

- Choose CNC when tolerances define performance.

- 3D printing, when defining success, focuses heavily on innovation.

- The best option is usually combining both, which is the flexibility of 3D printing and the precision of CNC machining.