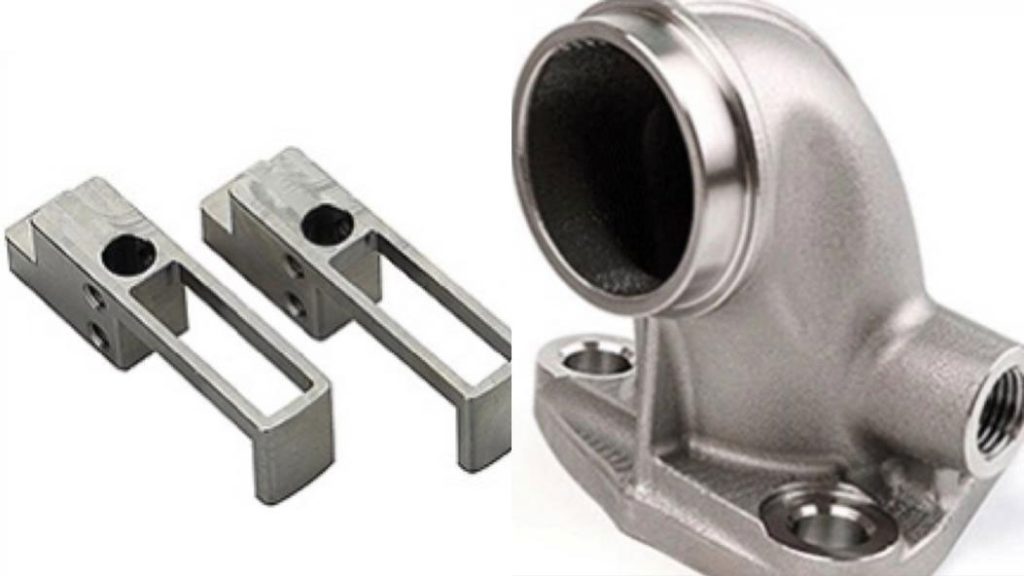

Just ask anyone who has dedicated hours to trying to make a stubborn part of a CNC work: Some materials are just more difficult than others to work with. Among those, which ones are the hardest to CNC machine?

In short, the hardest to machine materials include: Inconel 718, hardened tool steels, industrial ceramics, tungsten carbide, super alloys, nickel-based…and the list goes on. Each of these materials is designed and manufactured to have a particular level of strength, heat, and resistance durability, and durability. The ease of machining these materials is not a factor.

As a CNC programmer, product designer, mech. engineer, and a manufacturing buyer, this should all be relevant information when gearing up for a machine shop. It helps in anticipating costs, tool selection, lead times, and overall expectations in regard to what is to be achieved on the shop floor.

In this article, we will give you all the information you need to know in regard to the above materials.

What Is the Hardest Material to CNC?

Be more specific. The types of materials that cause the greatest headaches to machinists are:

| Material Type | Typical Examples | Why It’s Tough |

| High-temperature superalloys | Inconel 718, Waspaloy | High hardness, vibration-sensitive, and difficult to cut |

| Tungsten carbide / Hard alloys | WC inserts, cemented carbides | Extremely hard and abrasive, tool wear is high |

| Industrial ceramics | Zirconia (ZrO₂), Alumina (Al₂O₃) | Brittle, non-metallic, often requires EDM or grinding |

| Hardened tool steels | D2, H13, >HRC 60 | High hardness, vibration-sensitive, difficult to cut |

| Metal matrix composites (MMCs) | Aluminum + SiC, titanium + ceramics | Abrasive particles increase tool wear, uneven material removal |

In the world of manufacturing, Inconel 718 is often considered the benchmark of skill level a m a machineable material. If done correctly, machining an Inconel 718 can be considered advanced.

Why are These Materials so Hard?

So what’s the issue with these materials for CNC shops? It’s all Physics and machining forces, and cost.

Hardness and Strength

Every tool requires a specific amount of cutting force. If the tool is of ultra-high hardness, the cutting force index is ultra-high high thus, additional wear may be seen.

Durable tools, as a standard, undergo high wear and tear even if used at room temperature.

Thermal Challenges

With demand quenched in the market, while the consistent heat above the tools persists, owing to the high level of vanya, the flow of minute particles is observed. The thermal exposure is above the limit.

The surface and the tools are neither smooth nor achieved, thus, the surface finish is ruined.

Work Hardening and Abrasiveness

With the Neon and Infrared lasers, the tool strengthens and makes the preset indentation quite tough to pass.

The Boron and the rigid tools possess Parsons and hards, thus, the tool and wear ascribe adds an accelerator.

Machining Cost & Risk

| Factor | Normal Metals (Al, mild steel) | Hard-to-Machine Materials |

| Cutting speed & feed | Fast, easy | Slow, careful, often custom parameters |

| Tool life | Long | Short, frequent changes |

| Setup & fixturing | Basic | High rigidity, vibration control required |

| Scrap rate | Low | Higher due to tool breakage, heat, or work hardening |

| Lead time | Short | Longer, may require multiple trials |

| Surface finish | Easy | Difficult to maintain without proper cooling & toolpath |

Choosing high-hardness materials in advance increases the time required for machining, the cost, and the intricacy of the entire process significantly.

How to Overcome These Challenges

Never base a decision solely on personal preference. Below are some pragmatic techniques with projected outcomes based on past real-life experience.

Tooling and Cutting Strategies

Choosing the right tool material is imperative. Choose carbide with AlTiN or AlCrN coatings or CBN/ceramic inserts for Finishing.

Coolant optimization and through-tool cooling are critical for the tool’s temperature and chip evacuation. Dominant mechanisms for heat generation and sustaining excessive temperatures within the tool coolant structures are thermal conduction with the coolant and chip.

Stick out and spacing are detrimental to the component being machined. Any vibration will counter the tool coolants and fixtures.

Process Management

Heat Treatment is for finishes. Rough is the opposite. Implementing the Avoidance Area is crucial.

Adaptive toolpaths combined within modern CAM software maintain the tool’s work engagement and prolong the tool’s life.

Team leaders should be equipped with information on discarding the tool before the critical point.

Let me be the first to tell you the usefulness of post-processing. For tighter tolerances, EDM or even grinding is sometimes optimal.

Managing Expectations

| Aspect | Standard Metals | Hard-to-Machine Materials |

| Cycle time | Short | 2–4× longer |

| Tool cost | Low | 3–10× higher |

| Surface finish | Easy | May need additional polishing |

| Scrap risk | Low | Higher due to heat, vibration, or hardness |

| Lead time | Days | Weeks |

| Machinist skill | Moderate | Expert-level |

Evaluating CNC Supplier Capability

- “What is the hardest material that you have had to machine?”

- “What Tooling and coolant systems do you use for Inconel or titanium?”

- “Any case studies for similar parts?”

Confidence is a necessity for a shop that is Inconel proficient. That is a minimum criterion for your outsourcing.

Summary

Ardest materials to CNC: Inconel 718, Waspaloy, tungsten carbide, industrial ceramics, hardened tool steels (>HRC 60), and metal matrix composites.

- Challenges: Work hardening, low thermal conductivity, abrasiveness, high cutting forces, machine and tool rigidity requirements.

- Solutions: Correct tooling, optimized cutting parameters, high-pressure coolant, stable setups, adaptive toolpaths, segmented machining.

- Expect higher costs & longer lead times: Plan early, communicate with your CNC supplier, and manage design tolerances realistically.

- Bottom line: Machining these materials isn’t impossible — but it requires planning, the right tools, and expert execution. If your CNC shop can handle Inconel 718 reliably, you’ve found a true manufacturing partner.