If you’ve ever tried to pick the “right” brass for CNC machining, you’ll know the challenge: there’s no single “best brass” — it depends entirely on what you’re making.That said, for most CNC applications, C360 stands out as the top choice. Its excellent machinability, consistent structure, and balance of strength and ductility make it ideal for precision components, while still being easy on cutting tools.

Let’s break it down so you can make a confident choice.

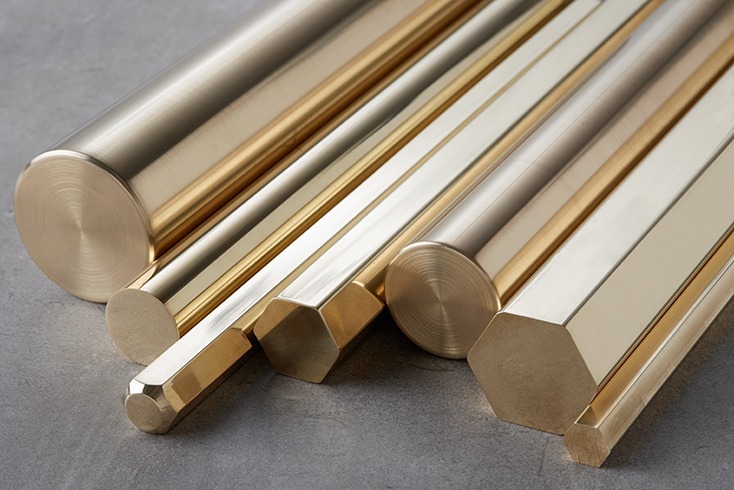

What Are the Different Types of Brass and Their Features

Brass is essentially copper + zinc, but the proportions change everything:

- More zinc → higher strength but slightly lower corrosion resistance.

- More copper → better corrosion resistance, softer, easier to form.

Brass is generally split into two main families:

- α-brass: up to ~36% zinc – softer, more ductile, easier to machine.

- β-brass: 36–46% zinc – stronger, harder, but less ductile.

| Category | Brass Grade | Typical Zinc % | Notes |

| α-brass | C360 | ~35% | The “free-machining” brass – CNC benchmark. |

| α-brass (Naval) | C464 | ~39% | Great corrosion resistance, especially in seawater. |

| α-brass | C260 | ~30% | Cartridge brass – excellent formability. |

| α-brass | C230 | ~15% | Red brass – high copper content, excellent corrosion resistance. |

read more:Best Practices for Machining, Maintaining, and Handling Brass CNC Parts

Why Brass Works So Well for CNC Machining

Brass is popular in CNC because it’s predictable, smooth, and easy to cut. Here’s why:

- High machinability – C360 sets the benchmark; it’s easy on tools.

- Low cutting friction – smooth cuts, less heat, longer tool life.

- Dimensional stability – holds ±0.01 mm tolerance, perfect for precision parts.

- Good thermal & electrical conductivity – ideal for connectors and heat sinks.

- Corrosion resistance – often no coating needed.

- Non-sparking cutting – safe in flammable environments.

CNC Machining Parameters (Reference)

| Process | Brass Grade | Cutting Speed (SFM) | Feed (in/rev) | Depth (in) | Coolant | Notes |

| Turning | C360 | 600–900 | 0.005–0.015 | 0.010–0.150 | Optional | High machinability, smooth finish |

| Turning | C464 | 500–800 | 0.003–0.010 | 0.010–0.120 | Recommended | Harder, slow down feed |

| Milling | C360 | 500–800 | 0.002–0.010 | 0.010–0.100 | Optional | Watch chip clearance |

| Milling | C464 | 400–700 | 0.002–0.008 | 0.010–0.080 | Recommended | Reduce depth to avoid overload |

| Drilling | C360 | 500–700 | 0.002–0.010 | 0.010–0.150 | Recommended | Ensure chip evacuation |

| Drilling | C464 | 400–600 | 0.002–0.008 | 0.010–0.120 | Recommended | Avoid overheating |

| Tapping | C360 | Moderate | 0.002–0.008 | — | Recommended | Smooth threads |

| Tapping | C464 | Lower | 0.002–0.006 | — | Recommended | Prevent thread tear-out |

Key Features That Make Brass CNC-Friendly

- Tensile strength: 300–600 MPa → strong yet cuttable

- Yield strength: ~100–400 MPa → holds shape during machining

- Brinell hardness: 80–150 HB → balances strength & machinability

- Machinability: C360 = 100% benchmark → fast cuts, minimal tool wear

- Ductility: High → easy bending, forming, threading

- Low friction & dimensional stability → smooth surface & long tool life

- Thermal & electrical conductivity: Excellent → ideal for heat-sensitive or electrical parts

- Non-sparking: Safe in explosive environments

Which Benefits Does Brass Offer in CNC Machining?

| Property | Typical Value / Description | CNC Machining Advantage |

| Tensile Strength | 300–600 MPa (depends on grade) | Strong enough for functional parts while still easy to cut |

| Yield Strength | ~100–400 MPa | Maintains shape during machining; resists deformation |

| Brinell Hardness | 80–150 HB | Balances strength and machinability; minimizes excessive tool wear |

| Machinability | C360 = 100% (industry benchmark) | High cutting speed, low tool wear, shorter cycle time |

| Corrosion Resistance | Good to excellent | Reduces need for protective coatings or surface treatments |

| Ductility | High, especially for high-copper grades | Easy to bend, form, and tap threads |

| Low-Friction Cutting | Smooth cutting, low heat generation | Cleaner surface finish, longer tool life |

| Dimensional Stability | Minimal warping during machining | Maintains high precision tolerances (±0.01 mm) |

| Thermal & Electrical Conductivity | Excellent | Ideal for heat sinks, electrical connectors, and related parts |

| Non-Sparking Cutting | No sparks during cutting | Safer in explosive or flammable environments |

| High Production Efficiency | Enables high-speed cutting | Reduces overall manufacturing costs |

| Superior Surface Finish | Smooth surface after machining | Minimizes post-processing |

| Ease of Drilling & Tapping | Easier than stainless steel or titanium | Improves efficiency for complex parts |

C360 vs C464 vs.C260 vs C230: Which Brass is Best for CNC Machining?

Let’s break down C360, C464, C260, and C230, plus a few other notable ones, in composition, features, pros/cons, cost, and applications.

In CNC machining, brass is generally classified into two categories:

- Alpha Brass (α-brass): Zinc ≤36%, uniform structure, highly ductile, easy to machine. Commonly used for stamping, drawing, and precision cutting.

- Beta Brass (β-brass): Zinc 36–46%, higher hardness and strength, suitable for load-bearing or wear-resistant parts, but slightly harder to machine.

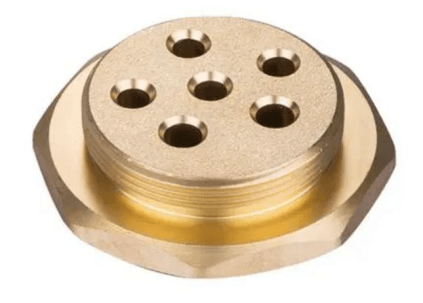

C360 – Free-Cutting Brass

- Type: α-β brass

- Composition: ~60% Cu, 35–37% Zn, 2.5–3.7% Pb

- Machinability: Industry benchmark (100%), low cutting resistance, ±0.01 mm tolerance achievable

- Pros: Excellent machinability, smooth surface finish, efficient for high-volume production

- Cons: Contains lead; not suitable for drinking water/food contact (check RoHS/REACH compliance)

- Cost: Medium

- Applications: Valves, fittings, gears, precision pins, electronic connectors

- Surface Treatment: Polishing, plating, brushing; natural golden sheen

C330 – Low-Lead Brass

- Type: α-β brass

- Composition: ~65% Cu, 35% Zn, <0.09% Pb

- Machinability: Close to C360, more eco-friendly

- Pros: Low lead, compliant with drinking water regulations, good thermal conductivity, better corrosion resistance than C360

- Cons: Slightly lower machinability, shorter tool life

- Cost: Slightly higher than C360

- Applications: Faucets, drinking water pipes, marine parts

- Surface Treatment: Polishing, plating with long-lasting shine

C353 – High-Leaded Brass

- Type: α-β brass

- Composition: ~62% Cu, 35% Zn, 2.8–3.5% Pb

- Machinability: Close to C360, higher strength, wear-resistant

- Pros: Easy to cut, good wear resistance, anti-galling

- Cons: Contains lead; not suitable for drinking water; slightly lower ductility

- Cost: Similar to C360

- Applications: Precision threads, bushings, gears

- Surface Treatment: Excellent plating, corrosion-resistant and decorative

C365 – Lead-Free Brass

- Type: α-brass

- Composition: ~63% Cu, 37% Zn, minimal Pb

- Machinability: Slightly lower than C360 but high-quality cuts possible with optimized tooling

- Pros: Lead-free, corrosion-resistant, scale-resistant

- Cons: Lower machinability, longer processing time

- Cost: Higher than C360/C330

- Applications: Drinking water valves, marine fittings, food machinery

- Surface Treatment: Polishing and plating; warm, natural color

C464 – Naval Brass

- Type: α-β brass

- Composition: ~60% Cu, 39% Zn, 0.75–1.0% Sn

- Machinability: Good, slightly lower than C360

- Pros: Extremely corrosion-resistant (marine), high strength, wear-resistant

- Cons: Slower cutting speeds, higher cost than standard brass

- Cost: Mid-high

- Applications: Ship propellers, seawater valves, pump shafts, bearing sleeves

- Surface Treatment: Polishing gives deep golden tone, combines decoration and corrosion resistance

C260 – Cartridge Brass

- Type: α-brass

- Composition: ~70% Cu, 30% Zn

- Machinability: Lower than C360, excellent ductility for cold forming

- Pros: High plasticity, excellent forming, stress-corrosion resistant

- Cons: Lower cutting efficiency, longer machining time

- Cost: Medium

- Applications: Shells, decorative hardware, musical instruments

- Surface Treatment: Excellent polishing, mirror-like finish

C230 – Red Brass

- Type: α-brass

- Composition: ~85% Cu, 15% Zn

- Machinability: Moderate, corrosion resistance extremely high

- Pros: High ductility, natural red-gold color, outstanding corrosion resistance

- Cons: Slow cutting, soft material, easy to deform

- Cost: Higher than standard brass

- Applications: Decorative pieces, architectural panels, marine fittings

- Surface Treatment: Maintains color without coating; can oxidize to antique finish

C220 – Commercial Bronze

- Type: α-brass (commercial bronze)

- Composition: ~90% Cu, 10% Zn

- Machinability: Low, suitable for cold forming

- Pros: Highly corrosion-resistant, reddish color, excellent ductility

- Cons: Not suitable for high-speed cutting, low efficiency

- Cost: Relatively high

- Applications: Architectural decoration, sculptures, musical instrument parts

- Surface Treatment: Naturally oxidizes to artistic bronze tones

Why C360 Brass is Best for CNC Machining?

- Outstanding machinability – C360 is the benchmark for 100% machinability in the machinability index (even steels are rated against it).

- Contains lead (2.5–3.5%) – The tiny lead inclusions act like a lubricant during cutting, producing small chips and reducing tool wear.

- Dimensional stability – Cuts cleanly without significant work-hardening, making it easy to achieve tight tolerances.

- Surface finish – Can achieve mirror-like surfaces straight off the CNC without much post-polishing.

- Cost-effective – Relatively affordable compared to exotic brass grades with special alloying elements.

How to Choose the Right Brass for CNC Machining

Choosing the right brass grade depends on machining efficiency, environment, regulations, and material properties:

Fastest CNC machining → C360 Free-Cutting Brass. High machinability, low tool wear, ideal for valves, fittings, and electronics.

Marine or corrosive environments → C464 Naval Brass. Tin content improves corrosion resistance, great for ship parts and pump shafts.

Lead-free / eco-friendly → C365 Lead-Free Brass. Meets RoHS and NSF standards, still easy to machine.

Cold forming or deep drawing → C260 Cartridge Brass. Excellent ductility, perfect for stamping and decorative parts.

Red-bronze look + corrosion resistance → C230 Red Brass. Used for pipes, architectural hardware, and decorative fittings.

| Grade | Machinability | Corrosion Resistance | Lead | Typical Use |

| C360 | ⭐⭐⭐⭐⭐ | Medium | Yes | Valves, fittings, electronics |

| C464 | ⭐⭐⭐⭐ | Very High | Yes | Marine parts, pump shafts |

| C260 | ⭐⭐⭐ | High | No | Decorative parts, stamping |

| C230 | ⭐⭐⭐ | Very High | No | Pipes, architectural hardware |

| C365 | ⭐⭐⭐ | Medium-High | No | Drinking water fittings, food machinery |

- High-speed production → C360

- Corrosion resistance / marine use → C464

- Lead-free / safe for water / food → C365

- Ductility or decorative parts → C260 / C230